Impedance combined type silencer

A composite muffler and sound absorbing body technology, which is applied to mufflers, machines/engines, engine components, etc., can solve the problems of poor high-frequency noise muffling effect, inability to achieve muffling effect, and poor low-frequency muffling performance, etc. Achieve the effect of increasing sound absorption, good noise reduction effect, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

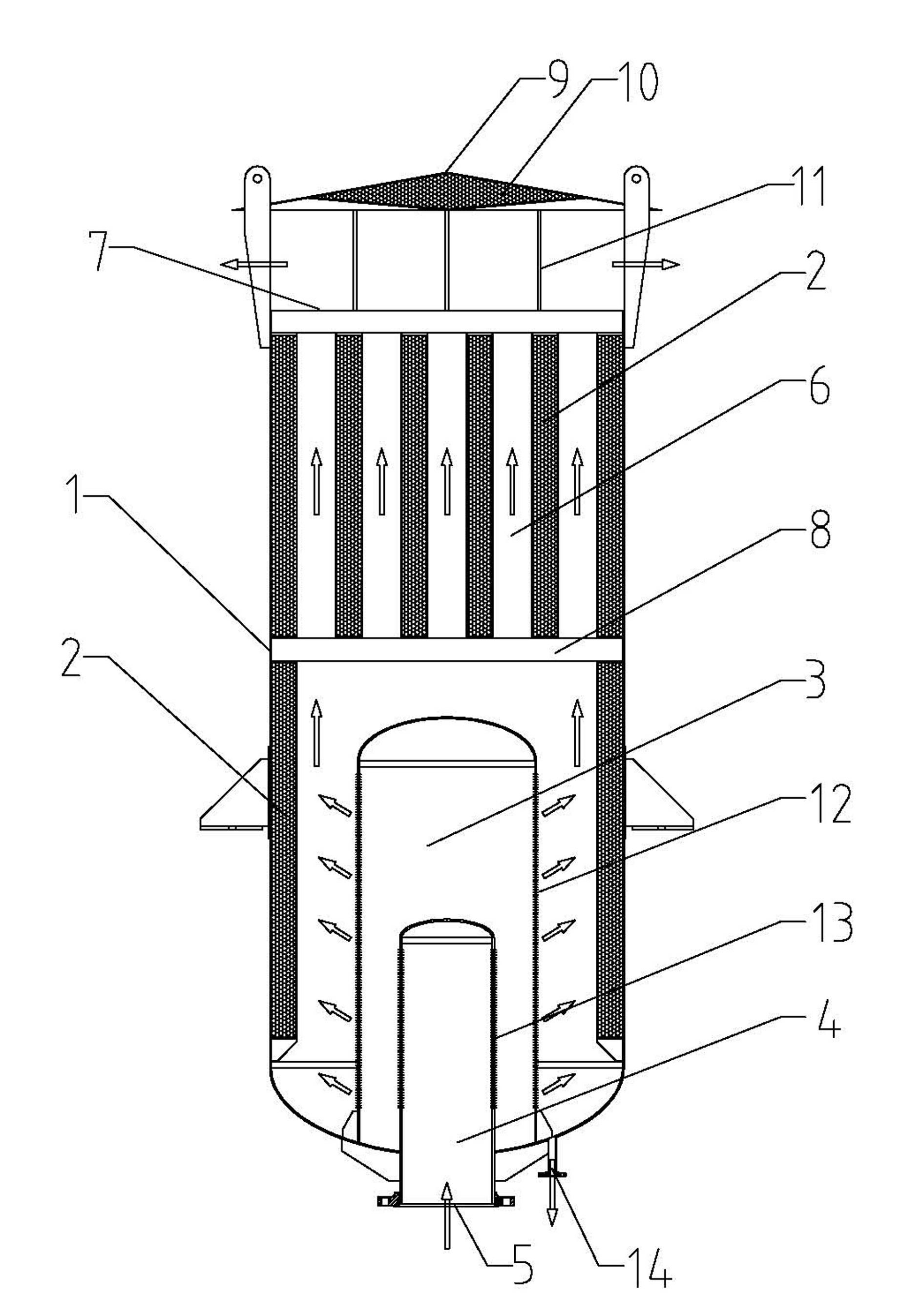

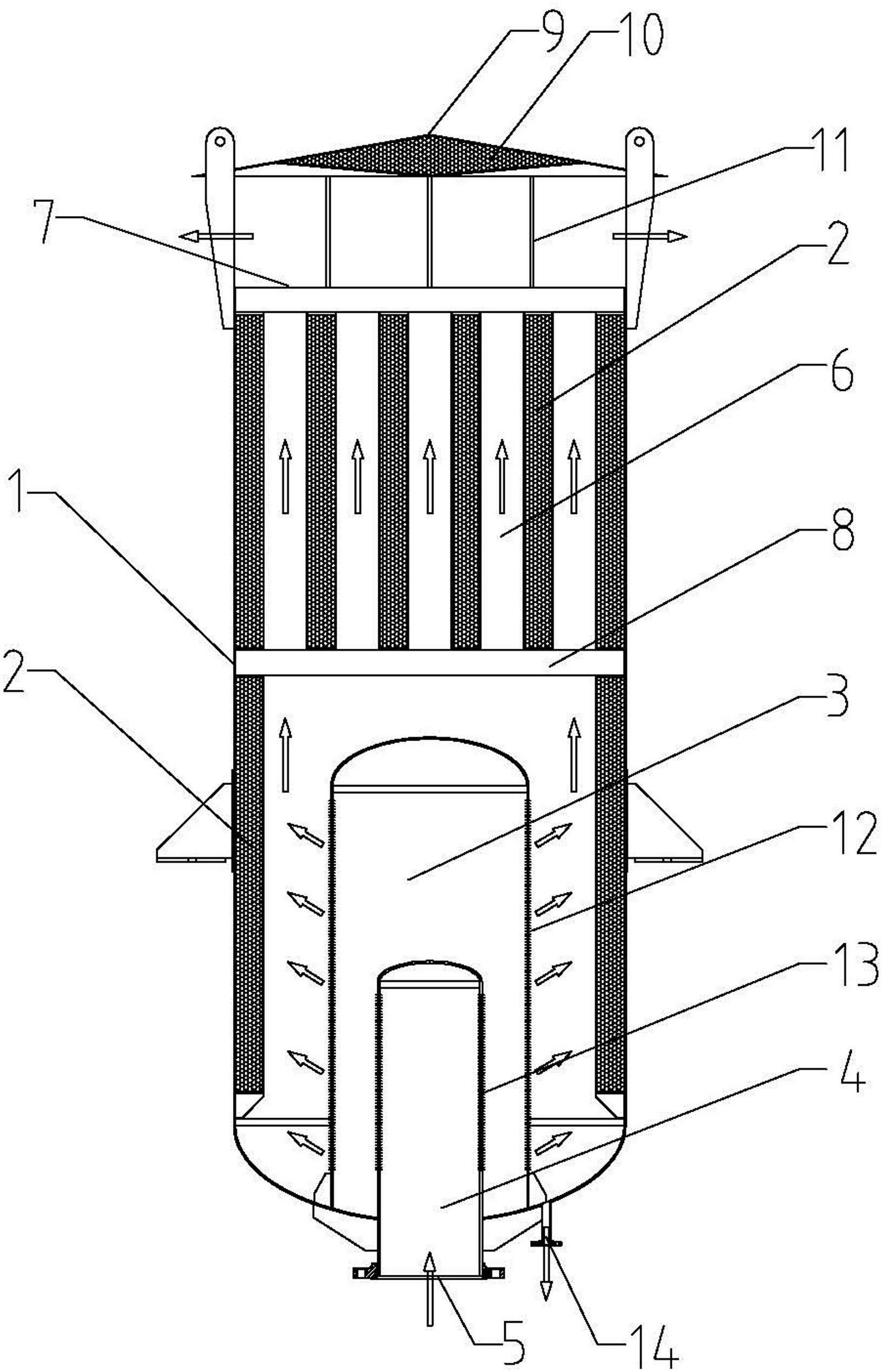

[0021] Such as figure 1 Shown: an impedance compound muffler, including a shell 1, the shell 1 is a cavity structure with a sound-absorbing layer 2 on the inner wall, and a small hole injection device 3 and a section are arranged in the lower chamber of the shell 1 The flow pressure reducing device 4, wherein the small hole injection device 3 is located in the middle of the casing 1 and forms a cavity with the casing 1, and the lower part of the cavity formed between the casing 1 and the small hole injection device 3 is provided with The outlet 14 and the small hole injection device 3 are also cavity structures, and the side wall of the cavity of the small hole injection device 3 is provided with an injection hole 12 with a diameter not greater than 1.5mm; the throttle and pressure reduction device 4 is located in the small hole A cavity is formed betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com