Novel three-point type bending machine hydraulic system with quick energy conservation

A hydraulic system and three-point technology, applied in the field of sheet metal bending machines, can solve problems such as inconvenience, large rebound of sheet metal, accident-prone maintenance, etc., and achieve the effect of convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

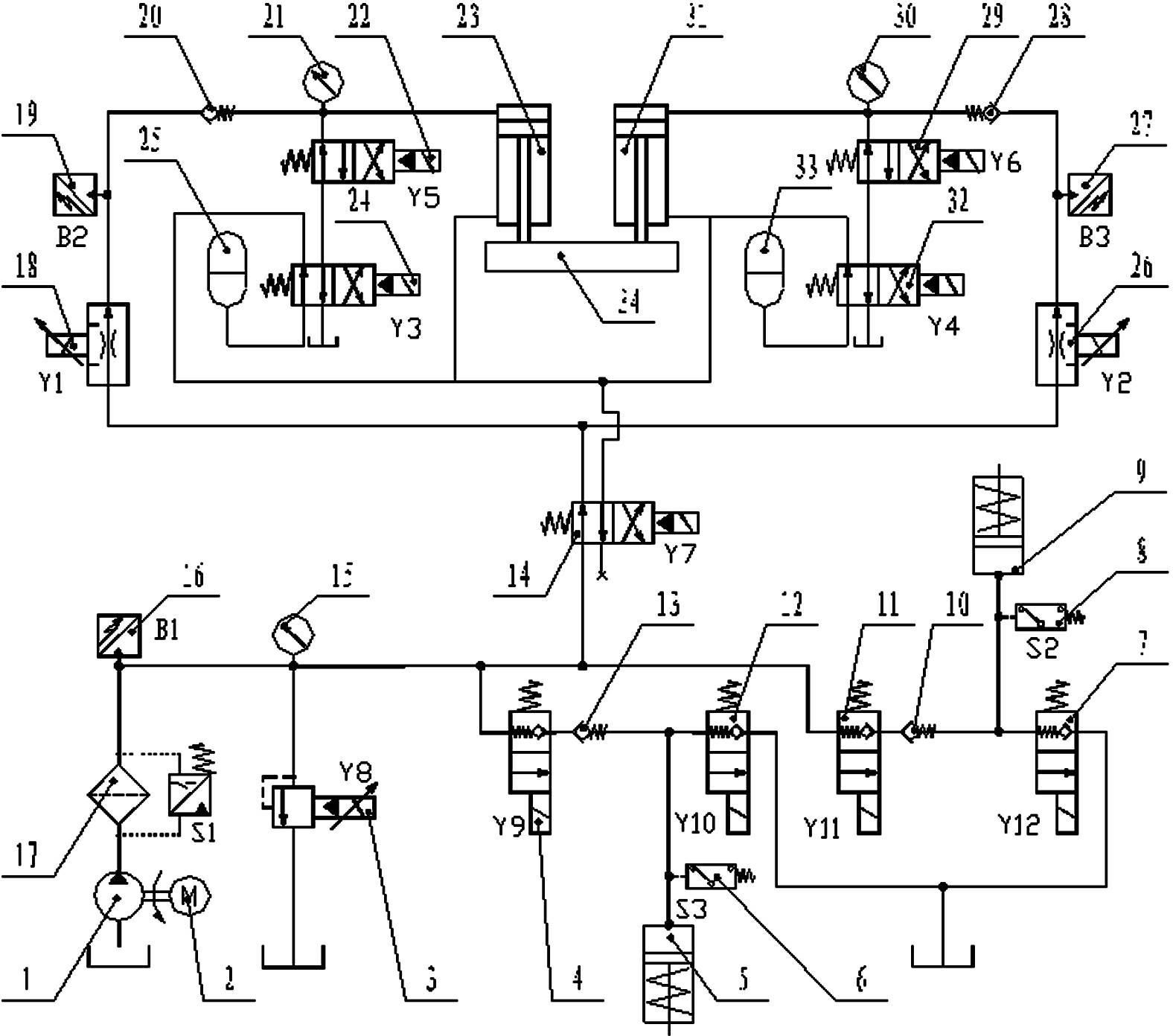

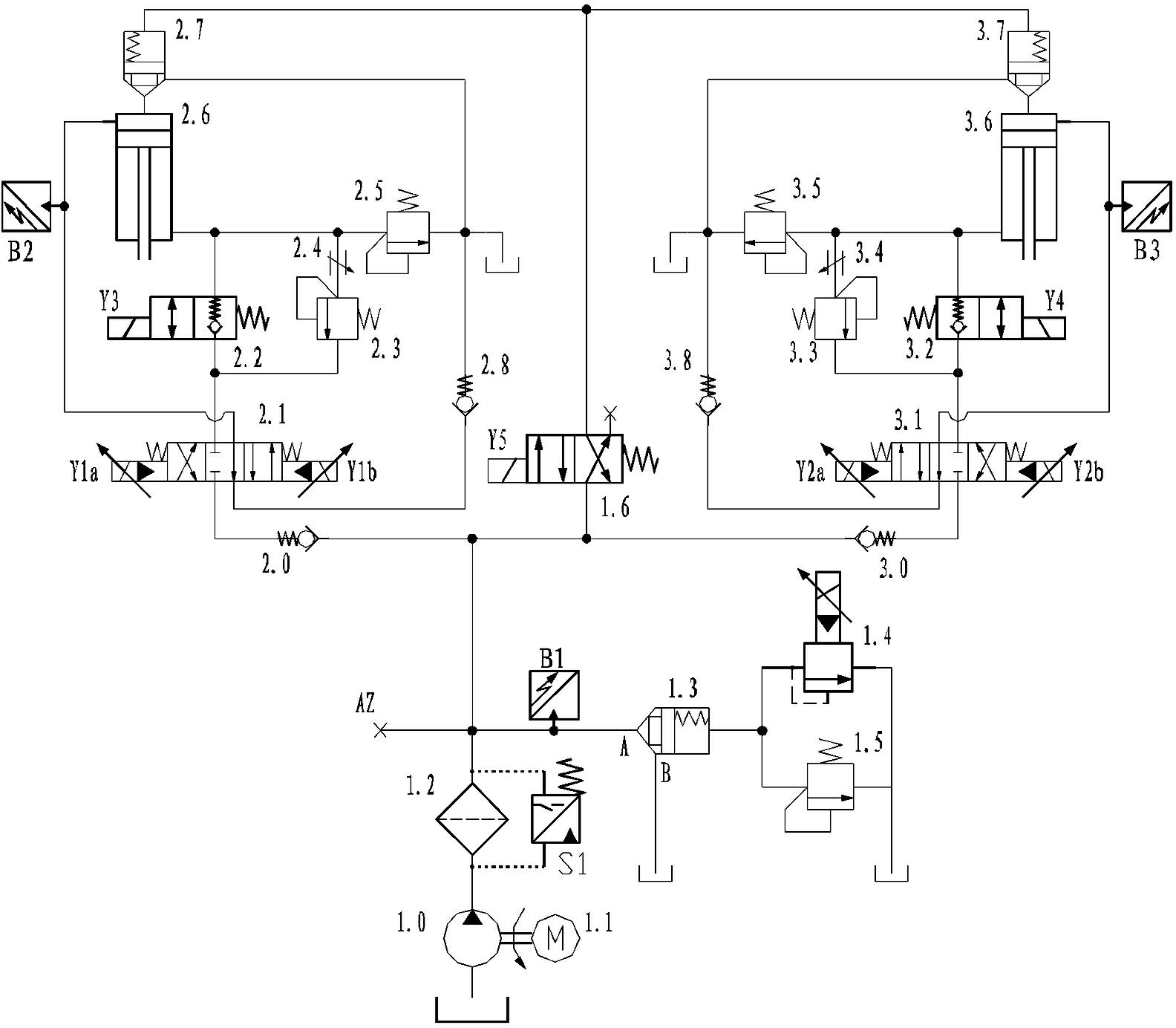

[0041] refer to figure 1 , the hydraulic system of the new fast and energy-saving three-point bending machine of the present invention includes a fuel tank, a power unit, a proportional overflow valve 3, a first reversing valve 14; a first proportional speed regulating valve 18, a first main oil cylinder 23, a first storage Energy control device, and the second proportional speed regulating valve 26, the second energy storage control device, the second master oil cylinder 31; and the upper knife plate 34; and the hydraulic clamping mechanism of the upper mold and the hydraulic clamping mechanism of the lower mold.

[0042] refer to figure 1 One end of the power unit is connected in parallel with one end of the proportional overflow valve 3 and then connected to the oil tank, and the other end of the power unit is connected in parallel with the other end of the proportional overflow valve 3 and then connected with the first reversing valve 14 . The power unit is composed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com