Microcamera module manufacturing method and product thereof

A technology of micro-camera and manufacturing method, which is applied in photography, image communication, television, etc. It can solve the problems of low degree of refinement of device structure, limited focus adjustment method, and low focus adjustment accuracy, and achieve small volume Miniaturization, ingenious structural design, reducing the effect of focusing components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

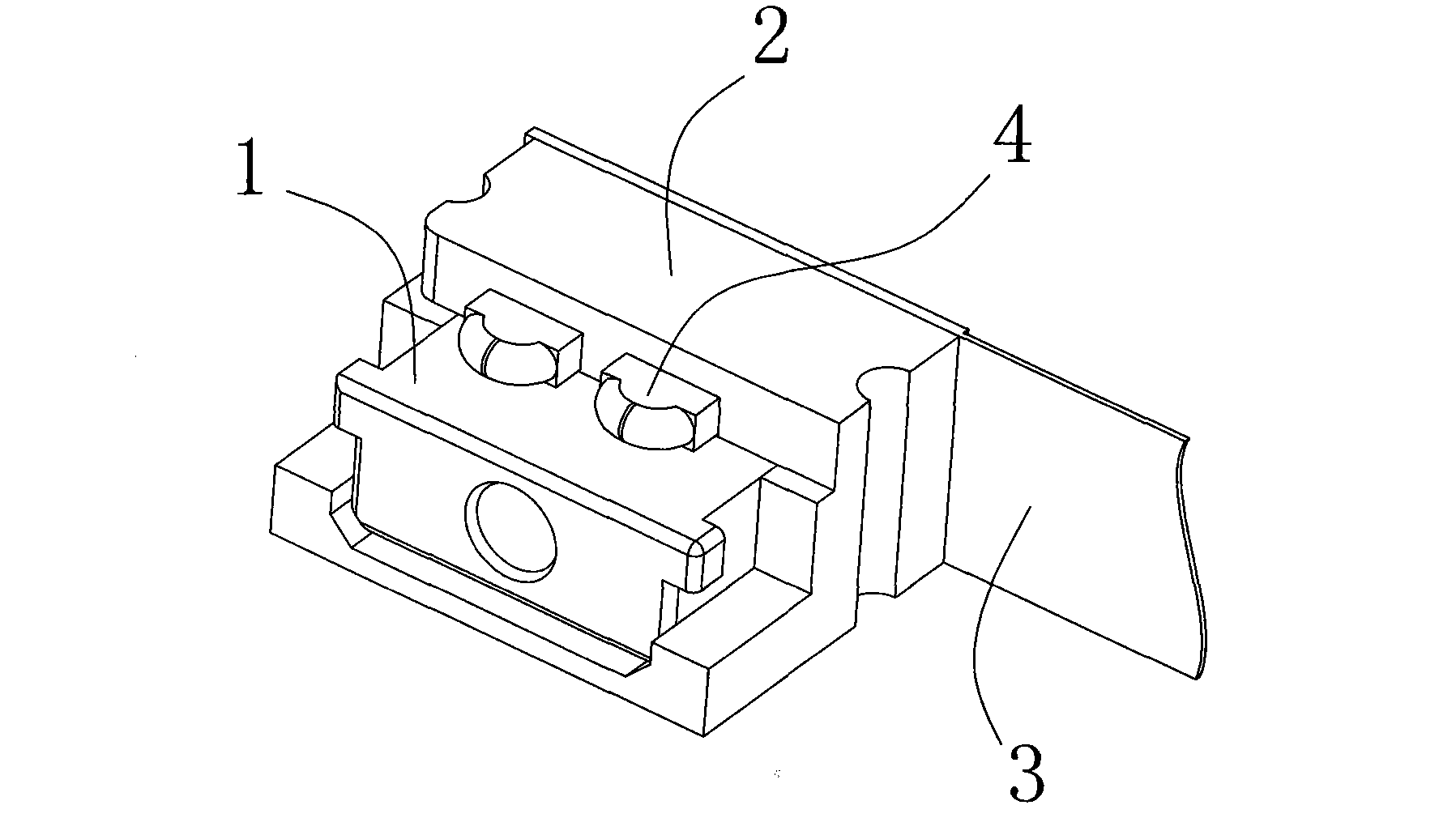

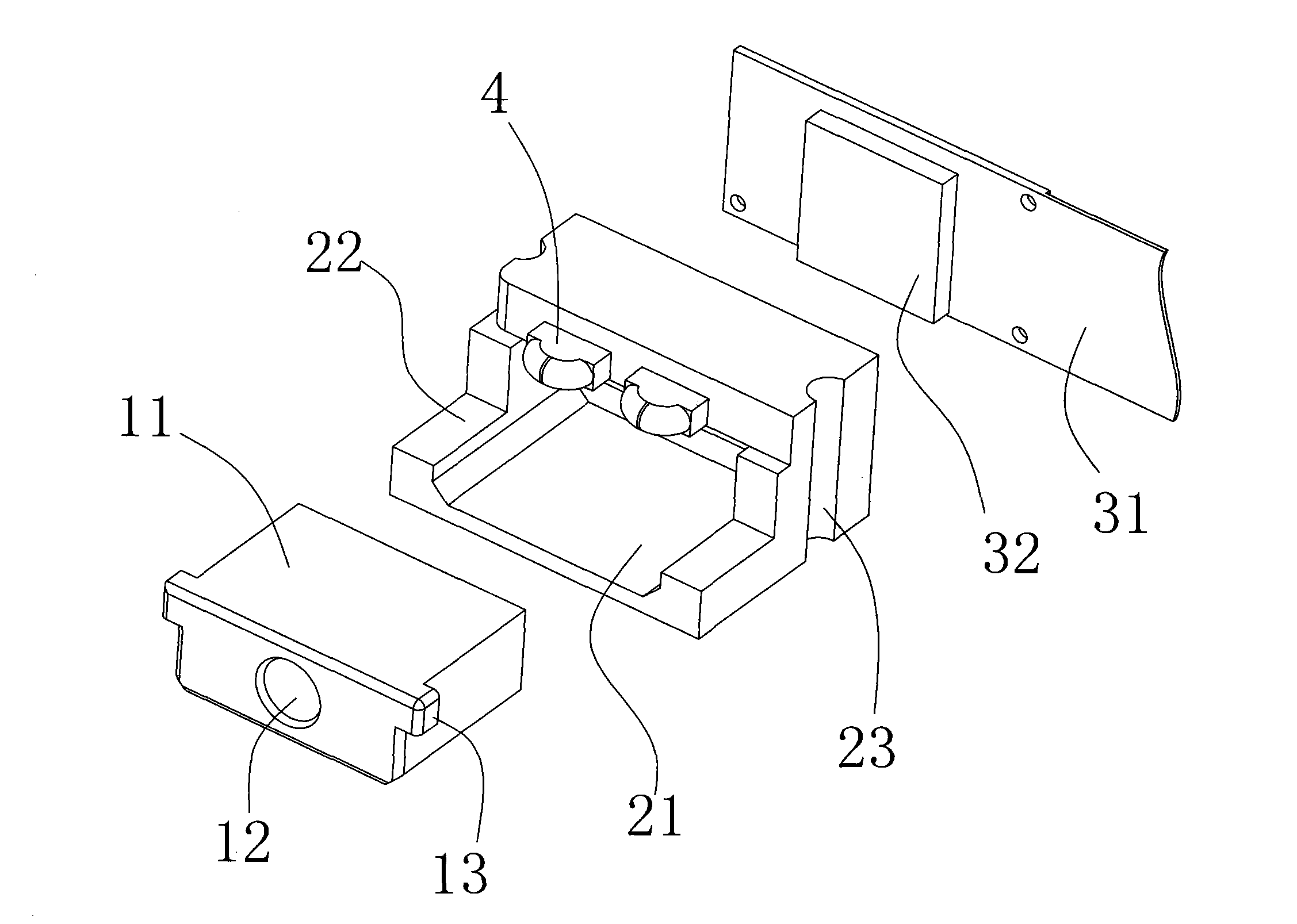

[0032] Embodiment 1: see figure 1 with figure 2 , a method for manufacturing a miniature camera module provided by an embodiment of the present invention, which includes the following steps:

[0033] (1) Prepare a small-volume lens 1 with a large viewing angle, which is used to focus on the subject;

[0034] (2) Prepare a mirror base 2, on the mirror base 2 is provided with an adjustment slot that is adapted to the outline of the small-volume large-view lens 1 and for the small-volume large-view lens 1 to slide back and forth on it twenty one;

[0035] (3) Corresponding to the front end of the adjustment channel 21, a notch 22 is provided at the front of the mirror base 2 to facilitate placing the small-volume, large-angle lens 1 on the adjustment channel 21;

[0036] (4) Prepare an image sensing component 3, and arrange the image sensing component 3 at the tail of the mirror base 2 corresponding to the position of the tail end of the adjustment channel 21;

[0037] (5) P...

Embodiment 2

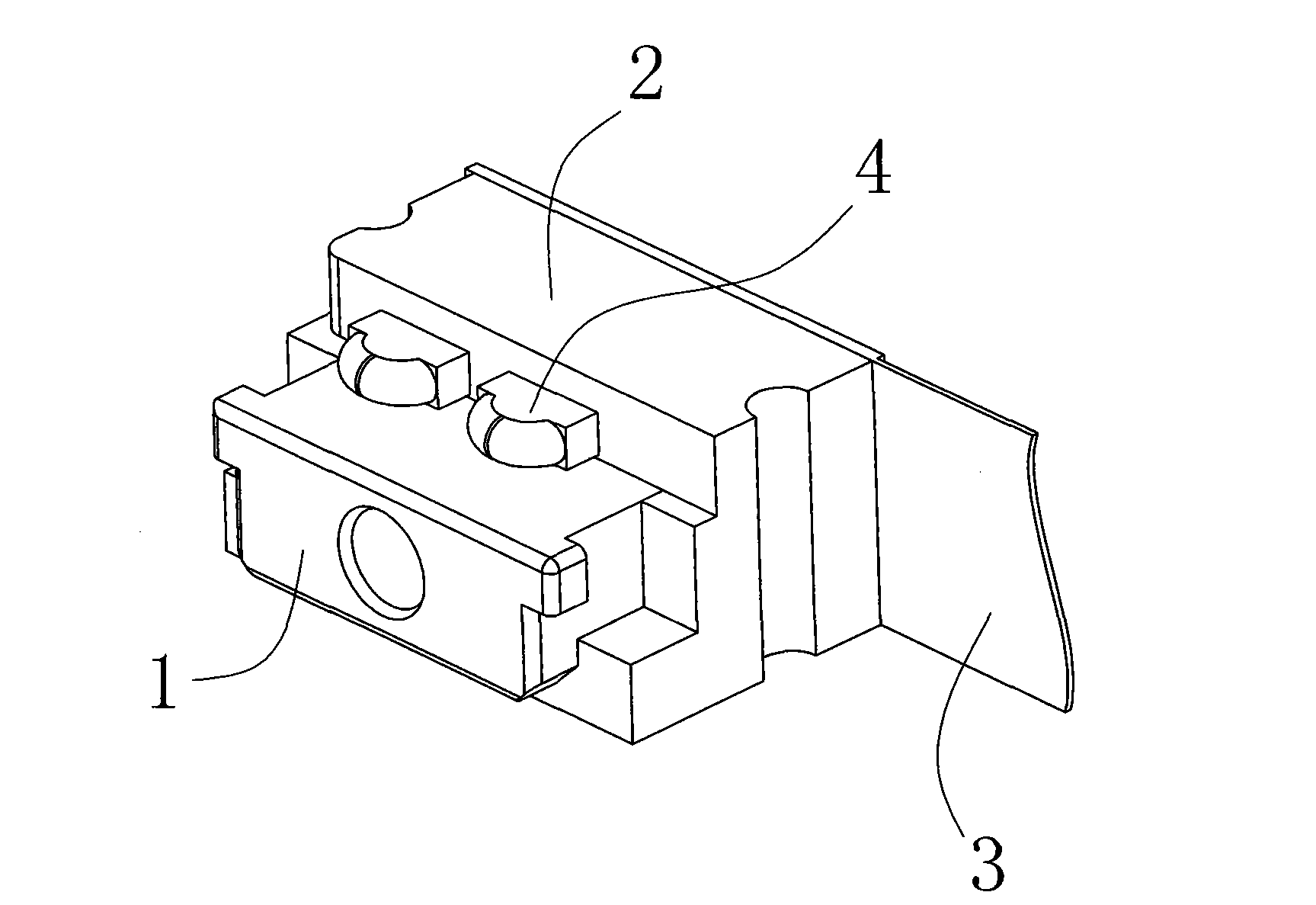

[0046] Example 2, see image 3 , a kind of micro-camera module manufacturing method and its products provided by this embodiment are basically the same as Embodiment 1, the difference is that the front part of the small volume and large viewing angle lens 1 is adjusted from the adjustment channel of the mirror base 2 21 sticks out.

Embodiment 3

[0047] Example 3, see Figure 4 with Figure 5 , a method for manufacturing a miniature camera module provided by an embodiment of the present invention, which includes the following steps:

[0048] (1) Prepare a small-volume lens 1 with a large viewing angle, which is used to focus on the subject;

[0049] (2) Prepare a mirror base 2, on the mirror base 2 is provided with an adjustment slot that is adapted to the outline of the small-volume large-view lens 1 and for the small-volume large-view lens 1 to slide back and forth on it twenty one;

[0050] (3) Corresponding to the front end of the adjustment channel 21, a notch 22 is provided at the front of the mirror base 2 to facilitate placing the small-volume, large-angle lens 1 on the adjustment channel 21;

[0051] (4) Prepare an image sensing component 3, and arrange the image sensing component 3 at the tail of the mirror base 2 corresponding to the position of the tail end of the adjustment channel 21;

[0052] (5) Pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com