Monitoring system and monitoring method for liquid level of fire-fighting high-altitude water tank for tunnel

A liquid level monitoring and remote monitoring system technology, applied in liquid level control, control/regulation system, pump control, etc., can solve problems such as increased use costs, tunnel fire safety threats, fire safety hazards, etc., to eliminate personal safety hazards , Improve monitoring efficiency and reduce maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

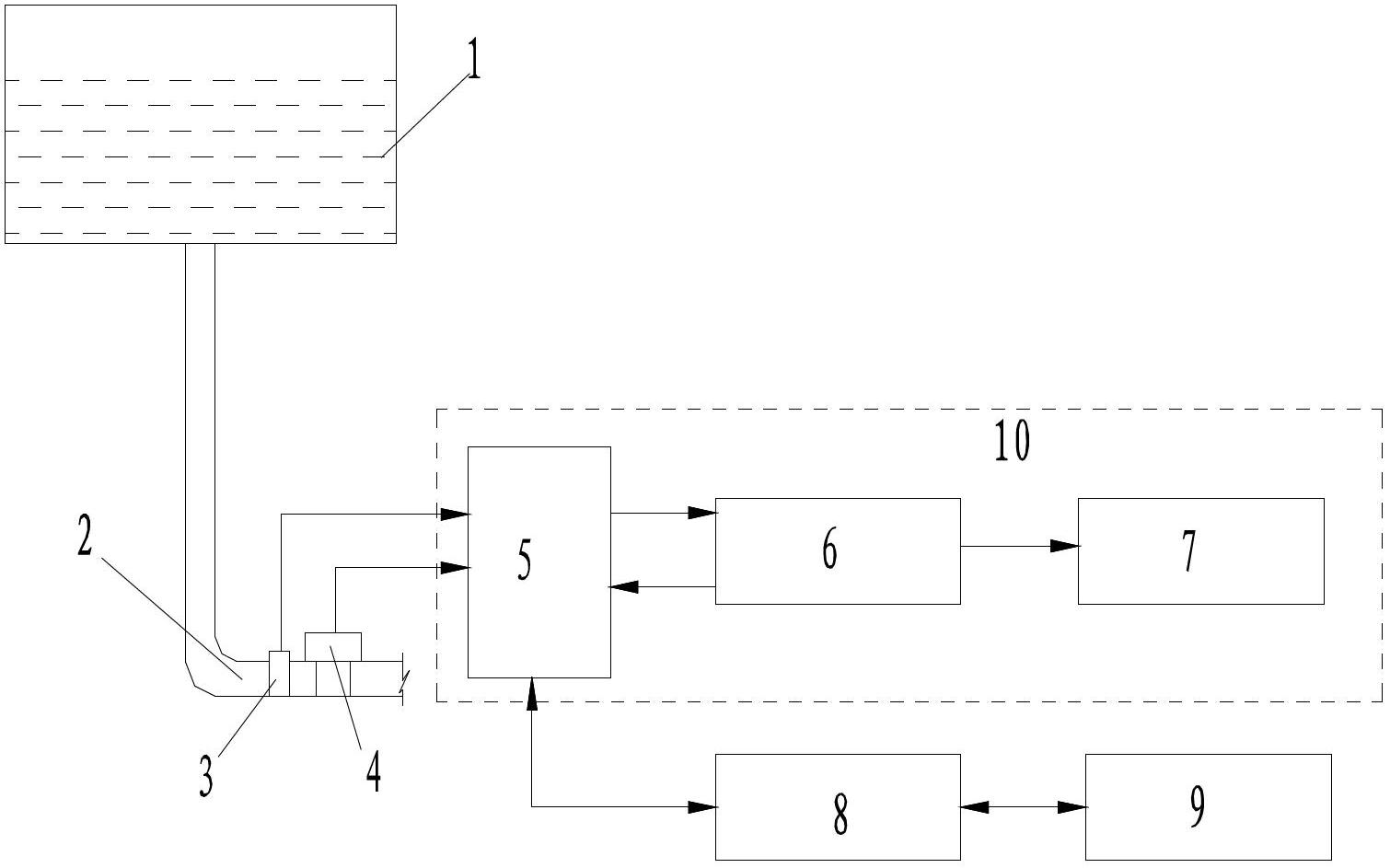

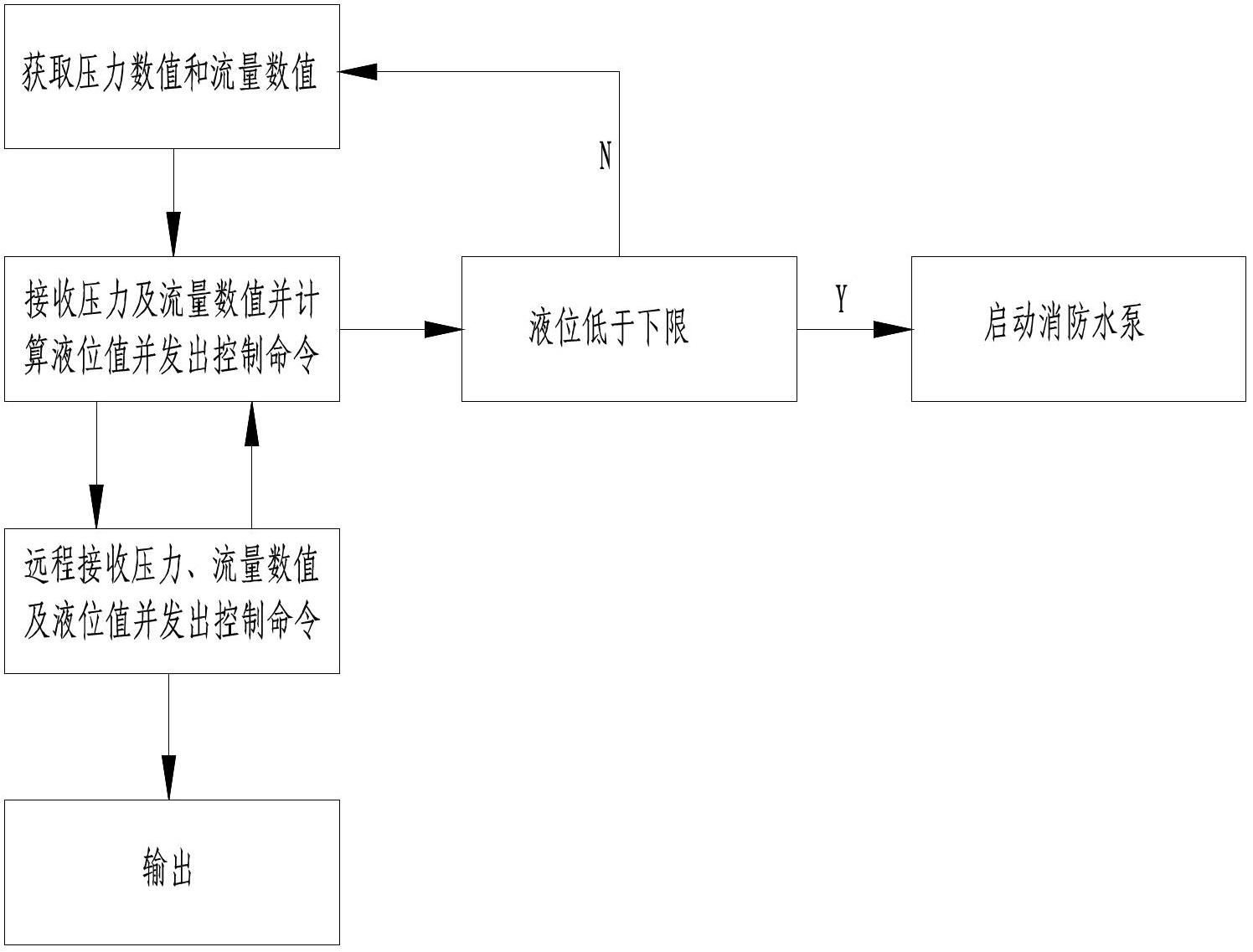

[0029] figure 1 It is a schematic diagram of the principle of the present invention, as shown in the figure: the liquid level monitoring system of the tunnel fire-fighting high-level pool of the present invention at least includes:

[0030] The pressure sensor 3 is arranged on the fire-fighting main pipe 2 from the high-level pool 1 to the tunnel to collect the water pressure signal in the main pipe 2; the pressure sensor of any structure capable of side hydraulic pressure in the prior art can be used; the high-level pool to the tunnel The main fire pipe of the tunnel is a fire pipe section laid horizontally in the tunnel, and communicates with the high-level pool through the upper and lower connecting pipes;

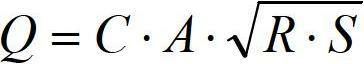

[0031] The flow sensor 4 is arranged on the fire-fighting main pipe 2 from the high-level pool 1 to the tunnel to collect the water flow signal in the main pipe 2; the flow sensor 4 can choose any flow sensor that is used to measure the flow in the pipe using existing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com