Rotary preheated and tubular preheater coupled air preheating system

A technology of air preheating and preheater, which is applied in the direction of heat exchanger, heat exchanger type, indirect heat exchanger, etc. It can solve the problem that the clogging and deposition of rotary ammonium bisulfate cannot be completely removed, it is not considered carefully, and the machine is shut down for cleaning problems such as ammonium bisulfate clogging and low-temperature corrosion, large design flexibility, and operating cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

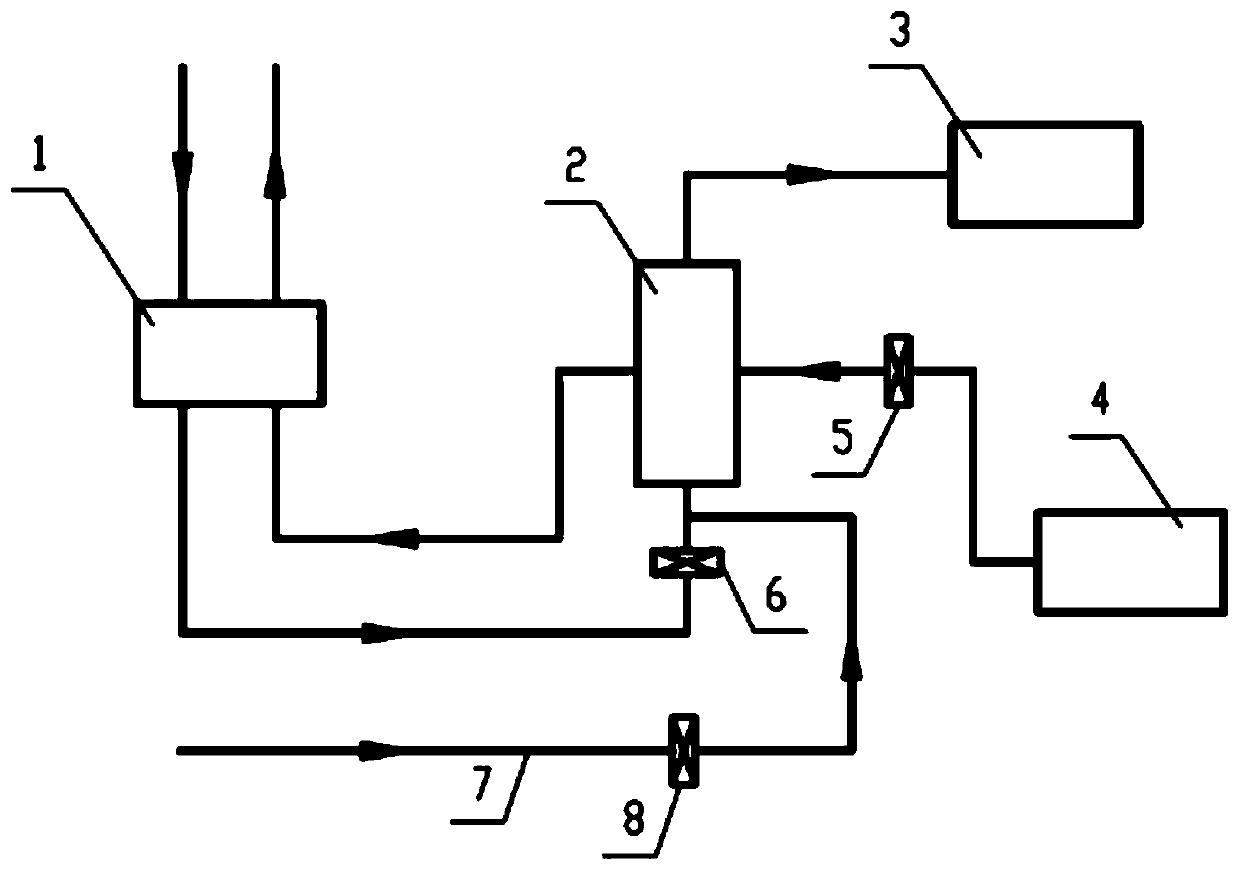

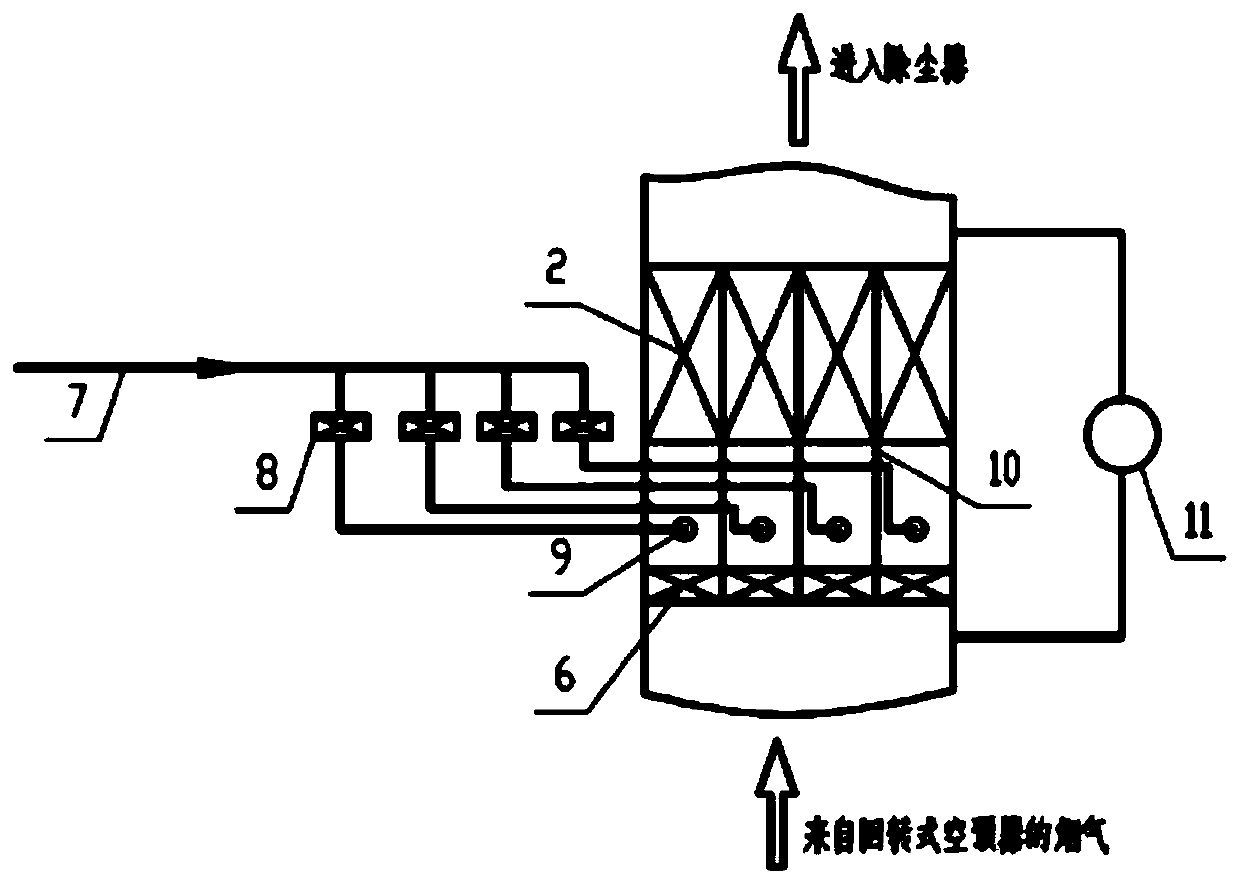

[0029] Such as figure 1 , figure 2 As shown, a 300MW coal-fired boiler unit is taken as an example for illustration.

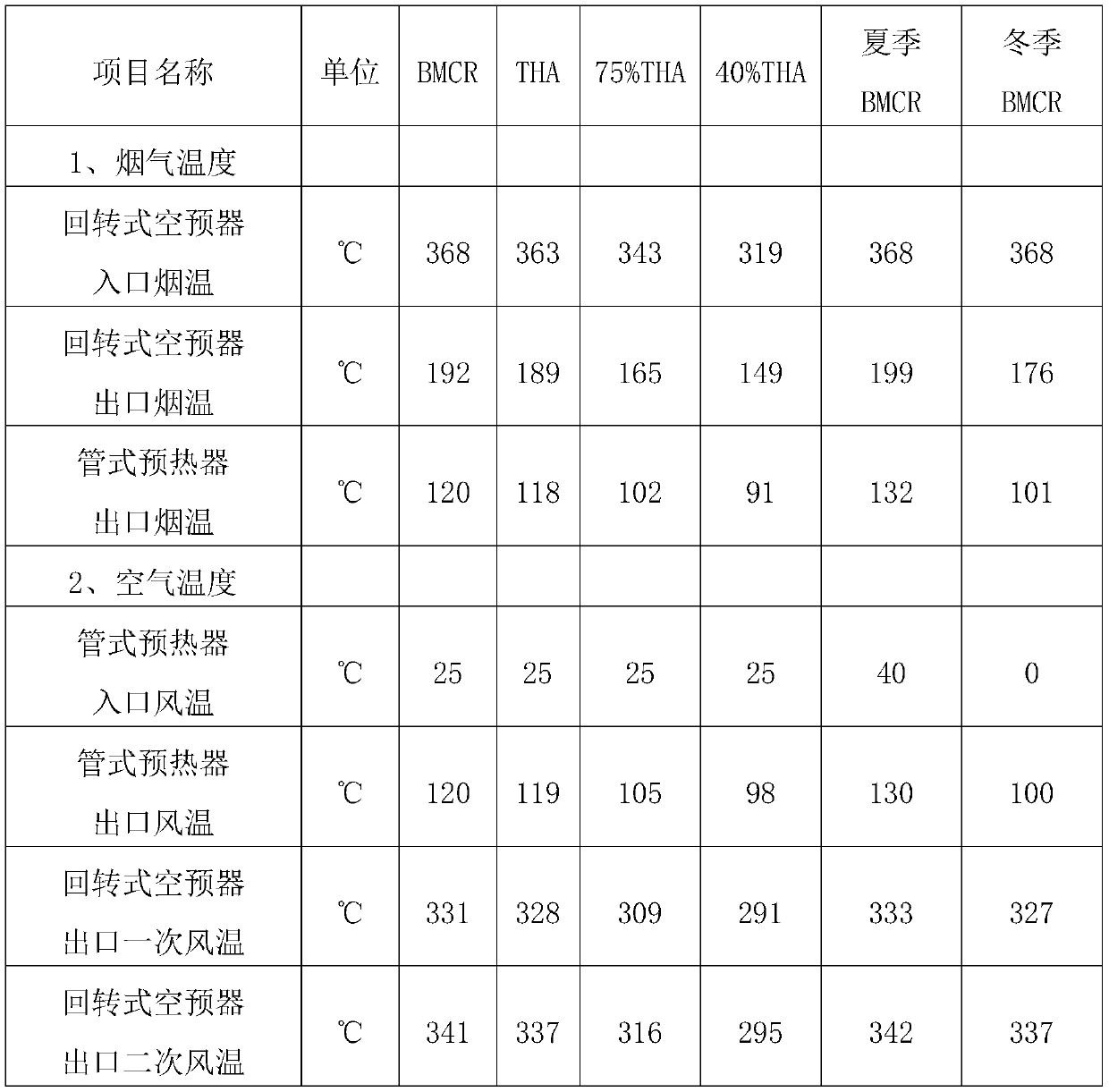

[0030] This project uses high-sulfur coal with a sulfur content of 4%. The unit uses the air preheating system of the present invention. A rotary preheater is arranged in the medium and high smoke temperature area of the SCR outlet, and a tubular preheater is arranged in the low smoke temperature area. After the flue gas comes out of the SCR, it passes through the rotary preheater, the tubular preheater, and then enters the dust collector; after the primary and secondary air comes out from the primary fan / supply fan, it passes through the tubular preheater, rotary preheater before entering the boiler. The rotary preheater is a three-chamber preheater, which is used to heat the air at the outlet of the tubular preheater; the tubular preheater is a bare tube heat exchanger, which is used to heat the air at the inlet of the rotary preheater , The flue gas g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com