Hydraulic pasture and straw cutting device

A hydraulic and guillotine cutting technology, which is applied to cutting equipment, agricultural machinery and tools, and applications, can solve problems such as inconvenient operation, affecting machine performance, and reduced productivity, so as to achieve convenient drying, shorten drying time, and use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

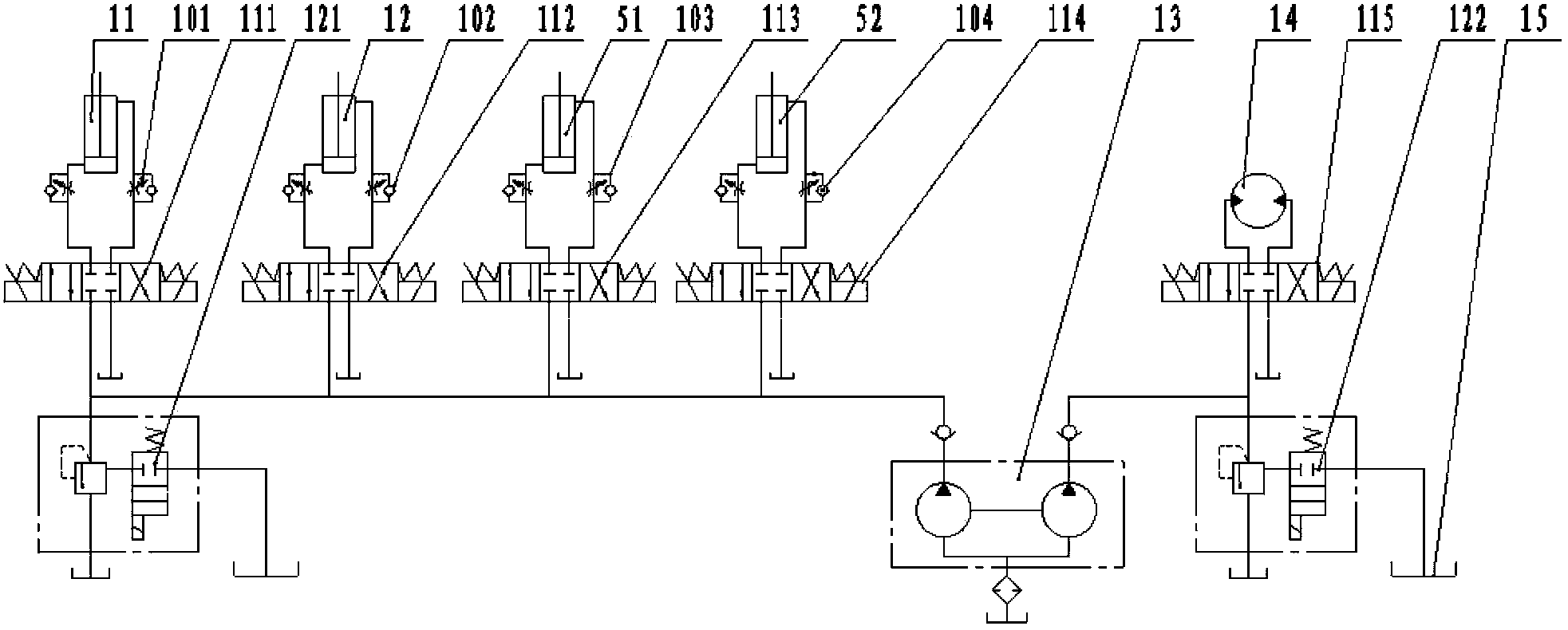

[0044] The cutting method used in the hydraulic pasture and straw cutting device of the present invention is to use a hydraulic method to carry out double-sided feeding and cutting of pasture and straw at the same time. The above-mentioned guillotine cutting operation is to press down vertically from the top to force the guillotine to be cut. The guillotine cutting length is determined according to the grid gap of the cutter device, and it is optional from 30 to 90 mm.

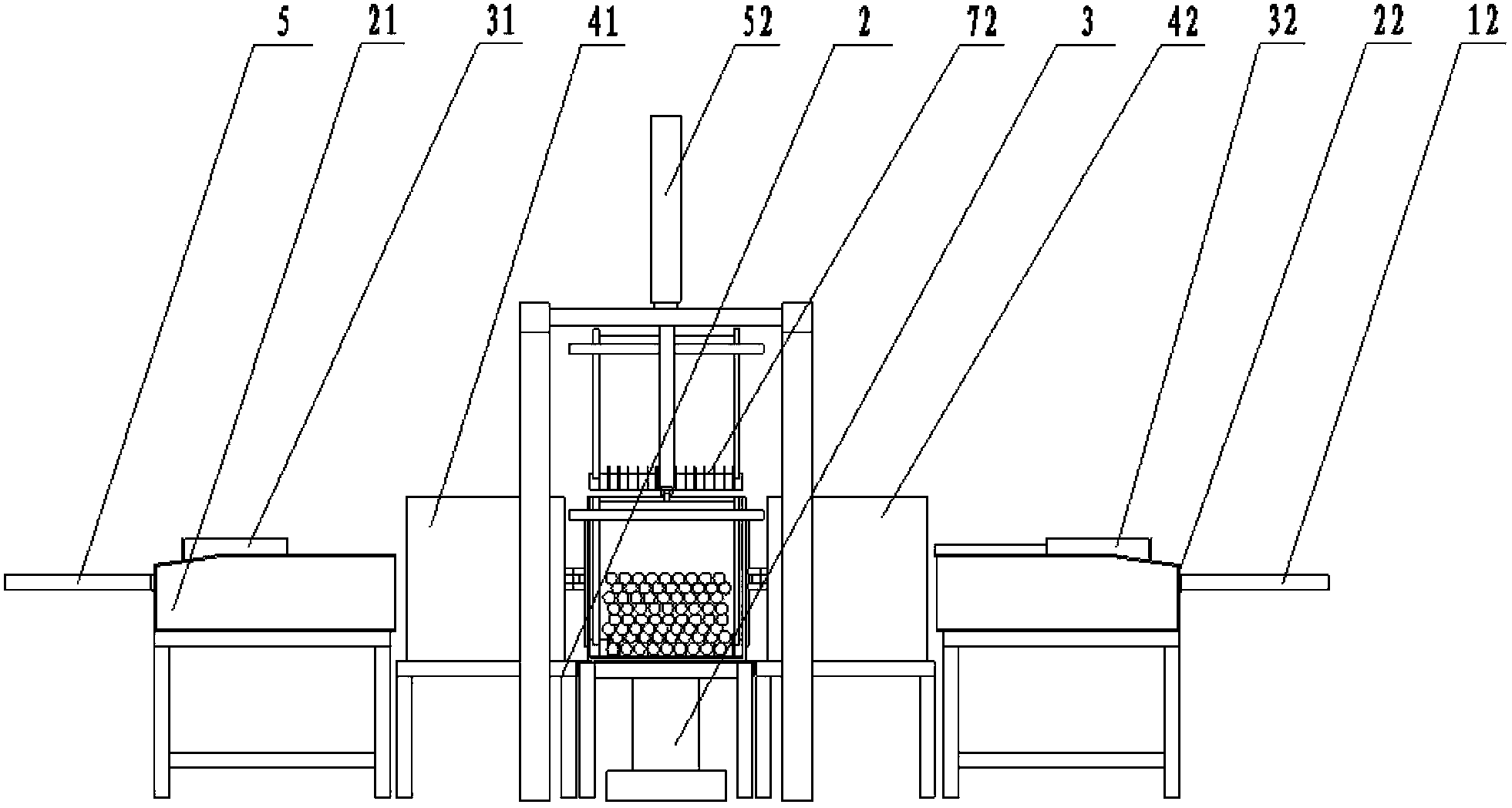

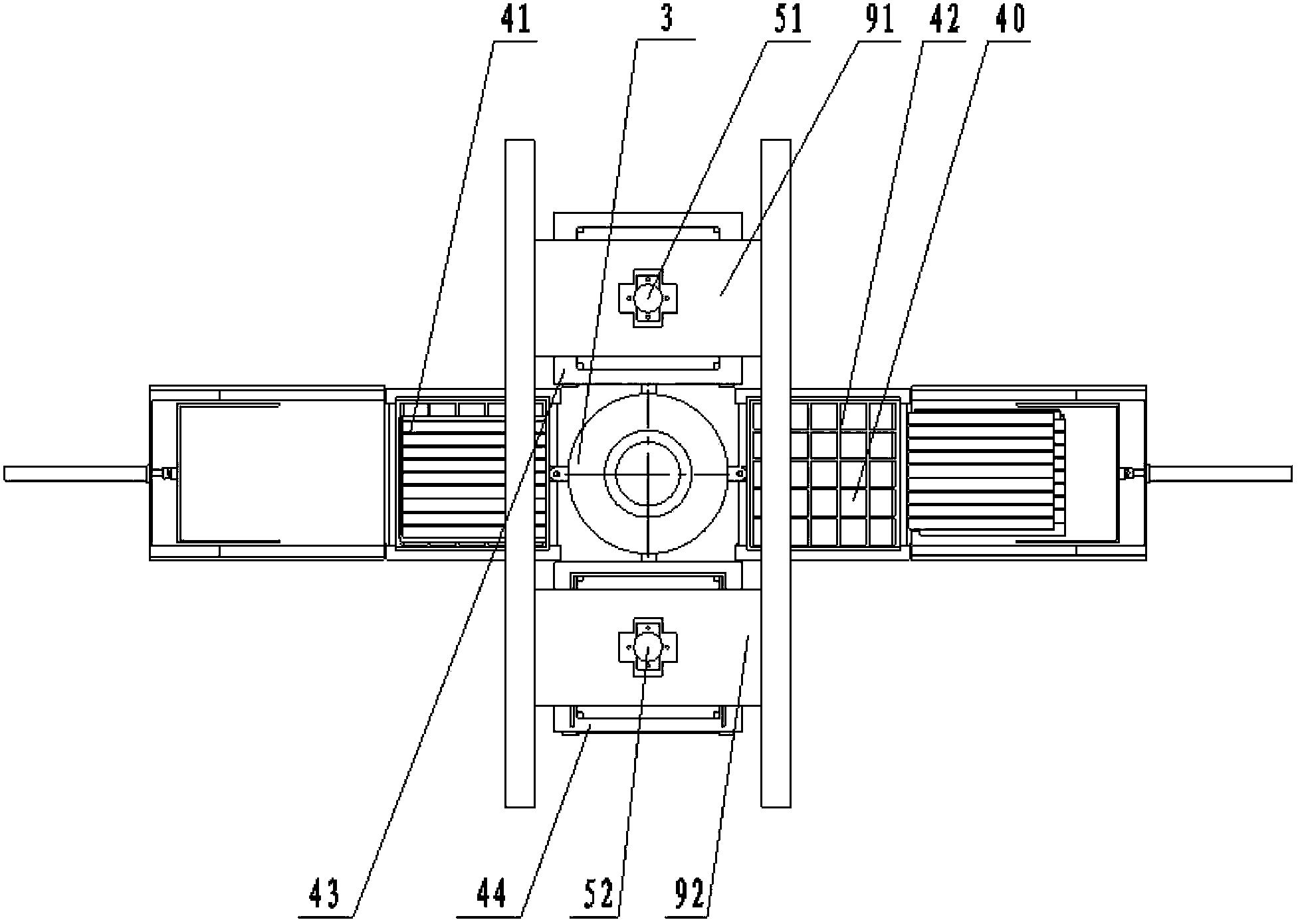

[0045] In order to realize the simultaneous operation of this double-sided feeding and guillotine cutting, the present invention provides a guillotine cutting device. Such as figure 1 , figure 2 , Figure 4 , Figure 5 In the shown embodiment, the guillotine cutting device of the present invention includes: a first conveying hydraulic cylinder 11, a second conveying hydraulic cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com