Air-pressure-type retraction self-destruction syringe

A pneumatic and syringe technology, applied in the field of syringes, can solve the problems of complex assembly, poor reliability of special assembly machinery, high cost, etc., and achieve the effects of reducing air compression, easy processing and molding, and reliable air sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

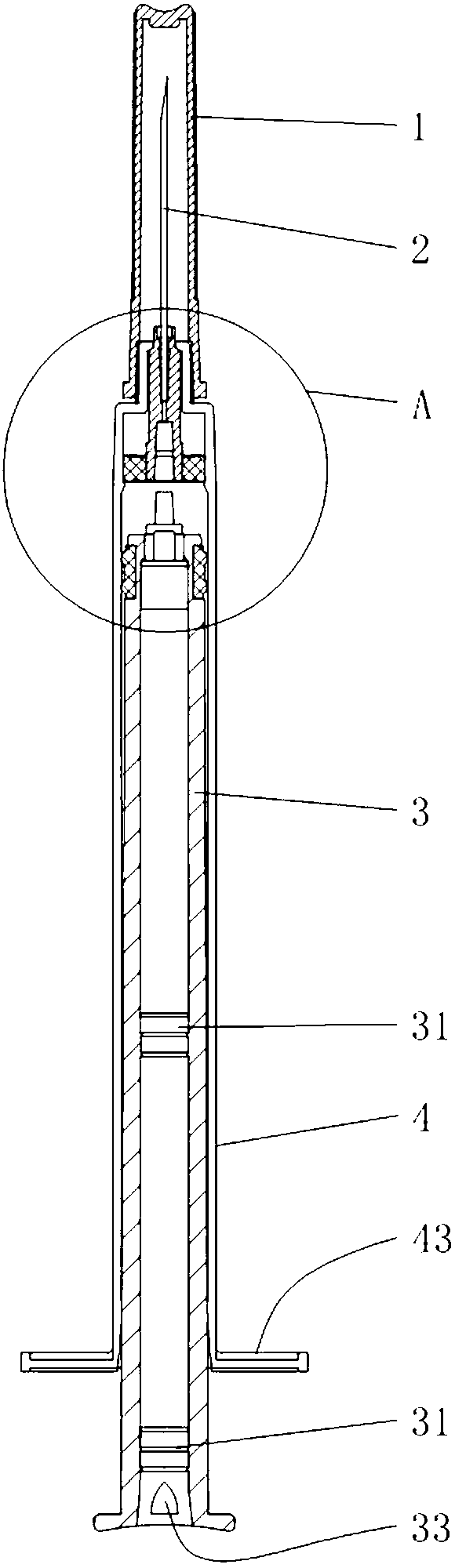

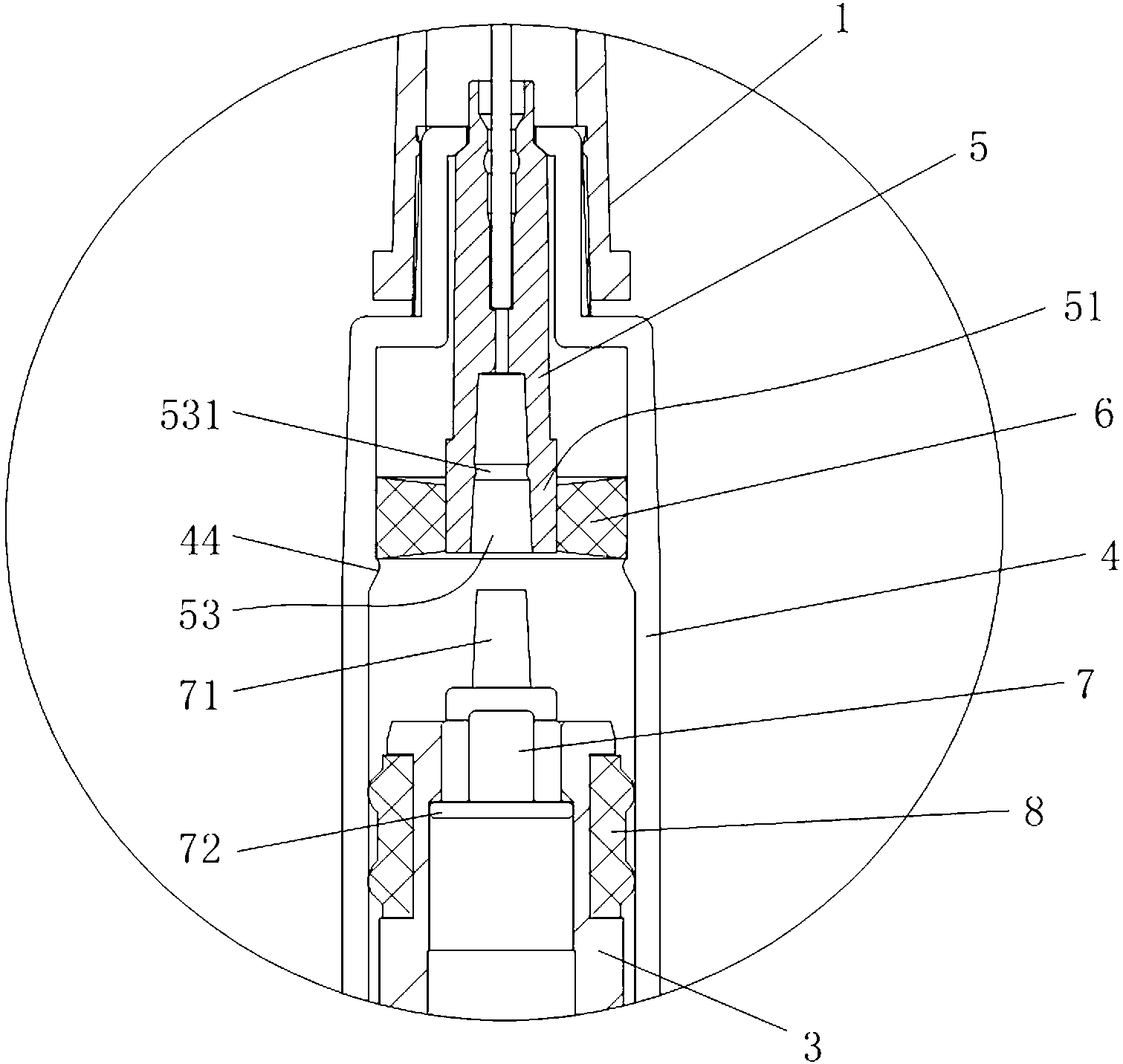

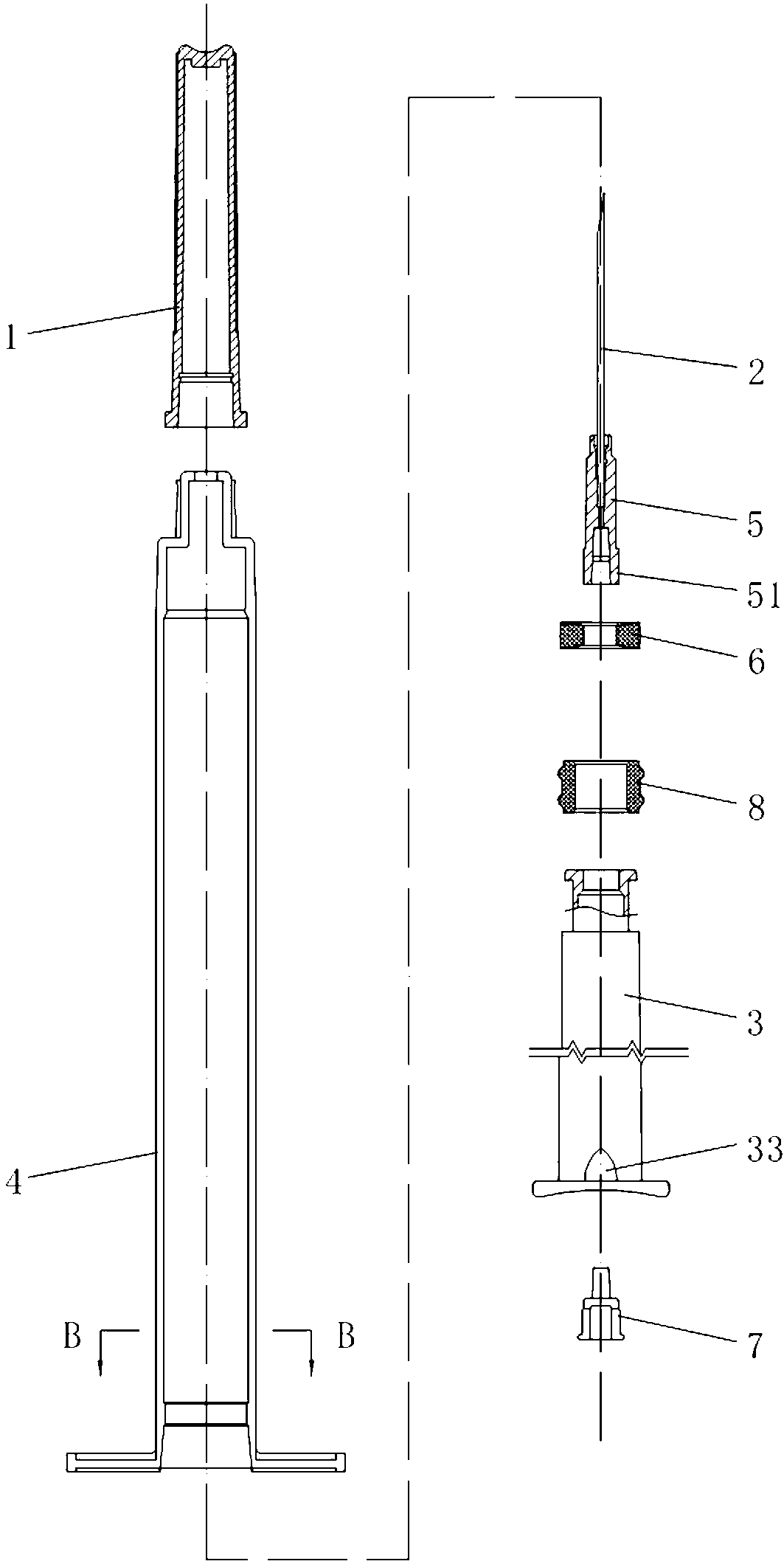

[0023] Such as figure 1 Shown in -6, a kind of air pressure retractable self-destructing syringe comprises injection barrel 4, cylindrical hollow injection rod 3, needle seat 5, sealing ring 6, piston 8 and sealing joint 7, and the center of needle seat 5 is provided with The needle 2 and the needle base 5 are mounted on the front end of the injection barrel 4 through the sealing ring 6 set on the lower end, the piston 8 is set on the outside of the front end of the injection rod 3, the sealing joint 7 is arranged on the inside of the front end of the injection rod 3, and the sealing joint 7 and the needle seat 5 are provided with a coupling structure that cooperates with each other. When the injection rod 3 is pushed to the front end of the syringe 4, the inner wall of the front end of the syringe 4 and the outer wall of the front end of the needle seat 5 are airtight, and the inner wall of the injection rod 3 There is a limit device 31 on the top that prevents the sealing jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com