Whirlwind thread tapping machine

A screw machine and cyclone technology, applied in the field of mechanical processing, can solve the problems of troublesome workpiece clamping, inability to be widely used, low efficiency of workpiece loading and unloading, etc., and achieve the effect of good processing quality, compact structure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further explained below in conjunction with the drawings:

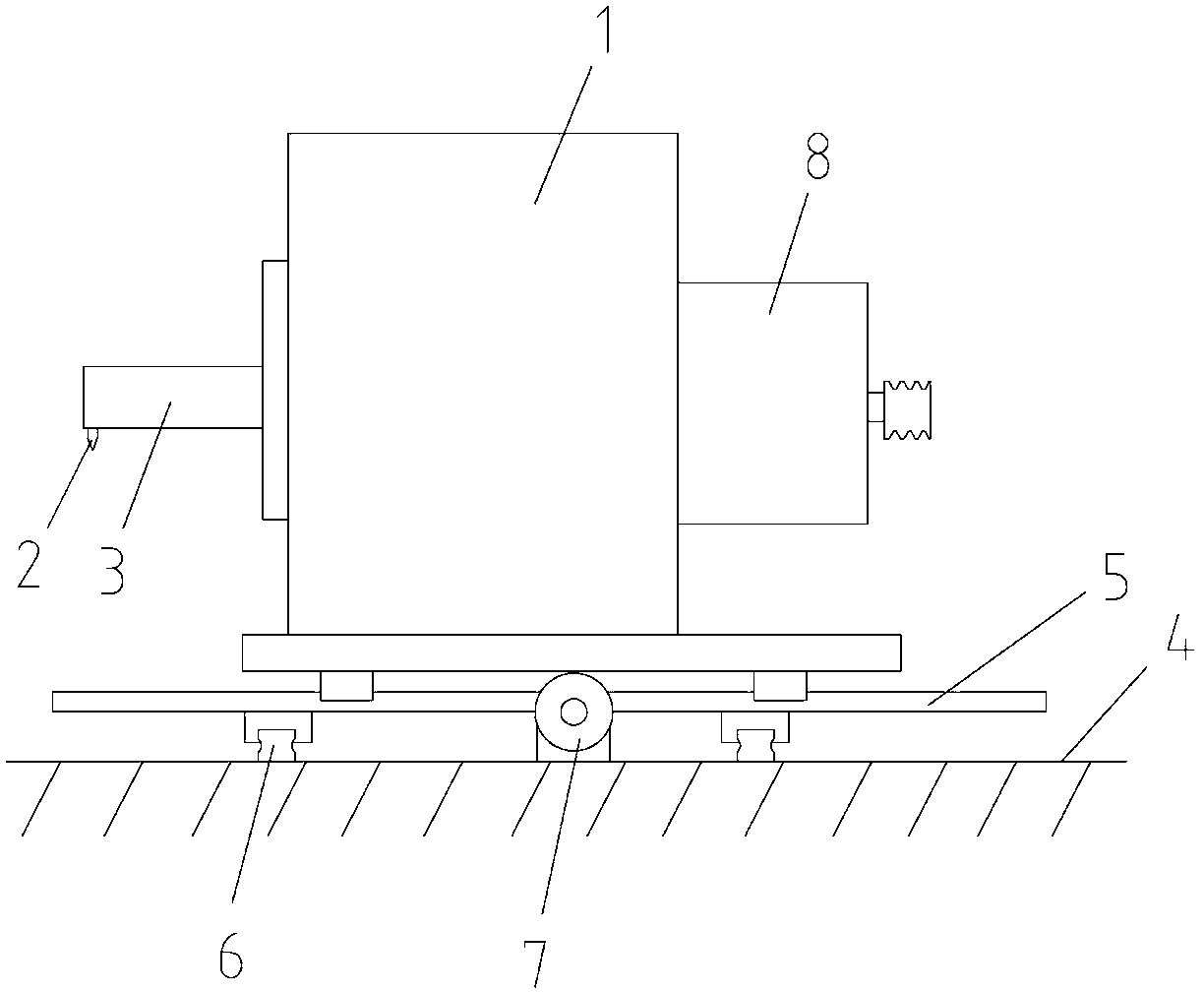

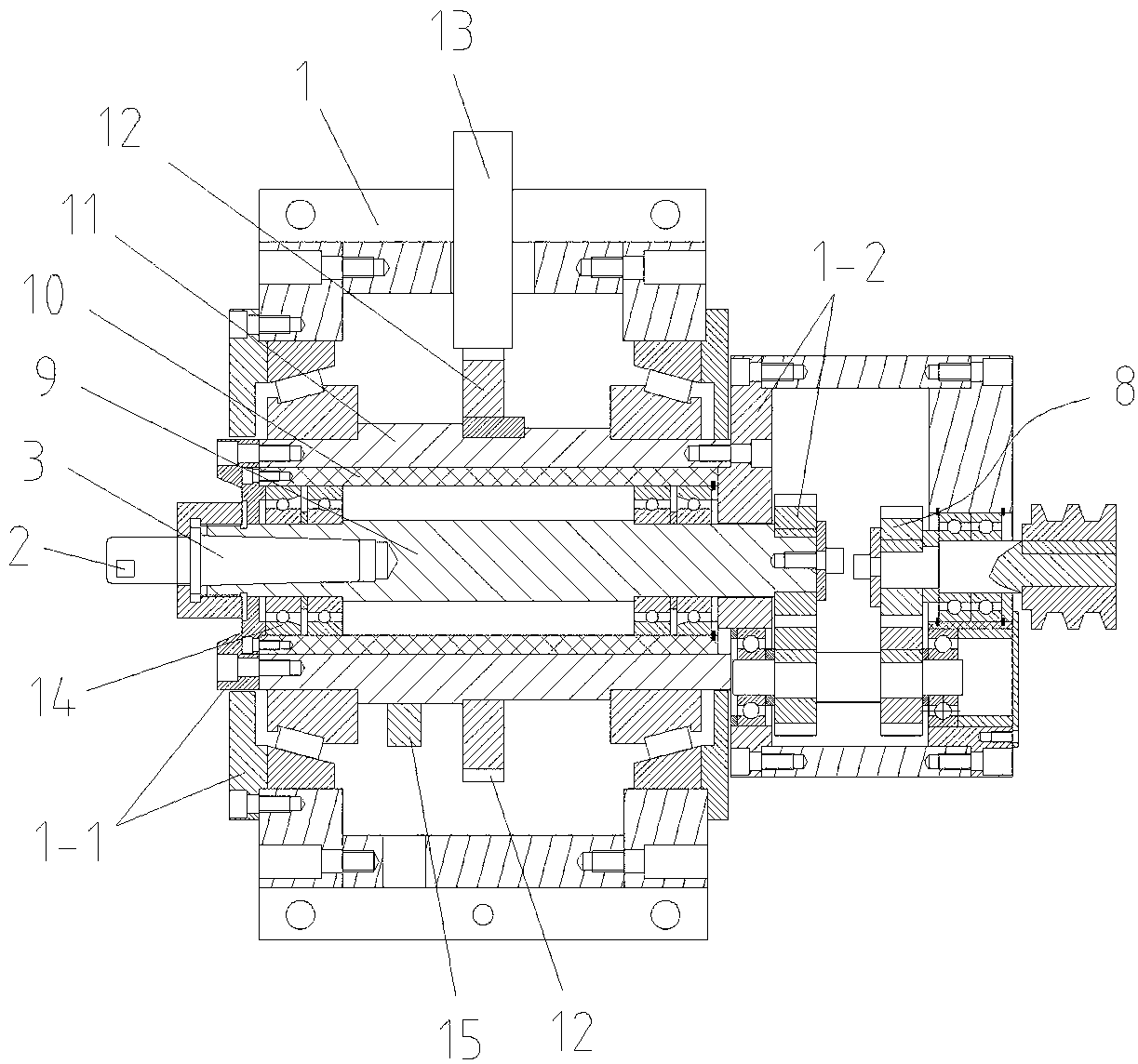

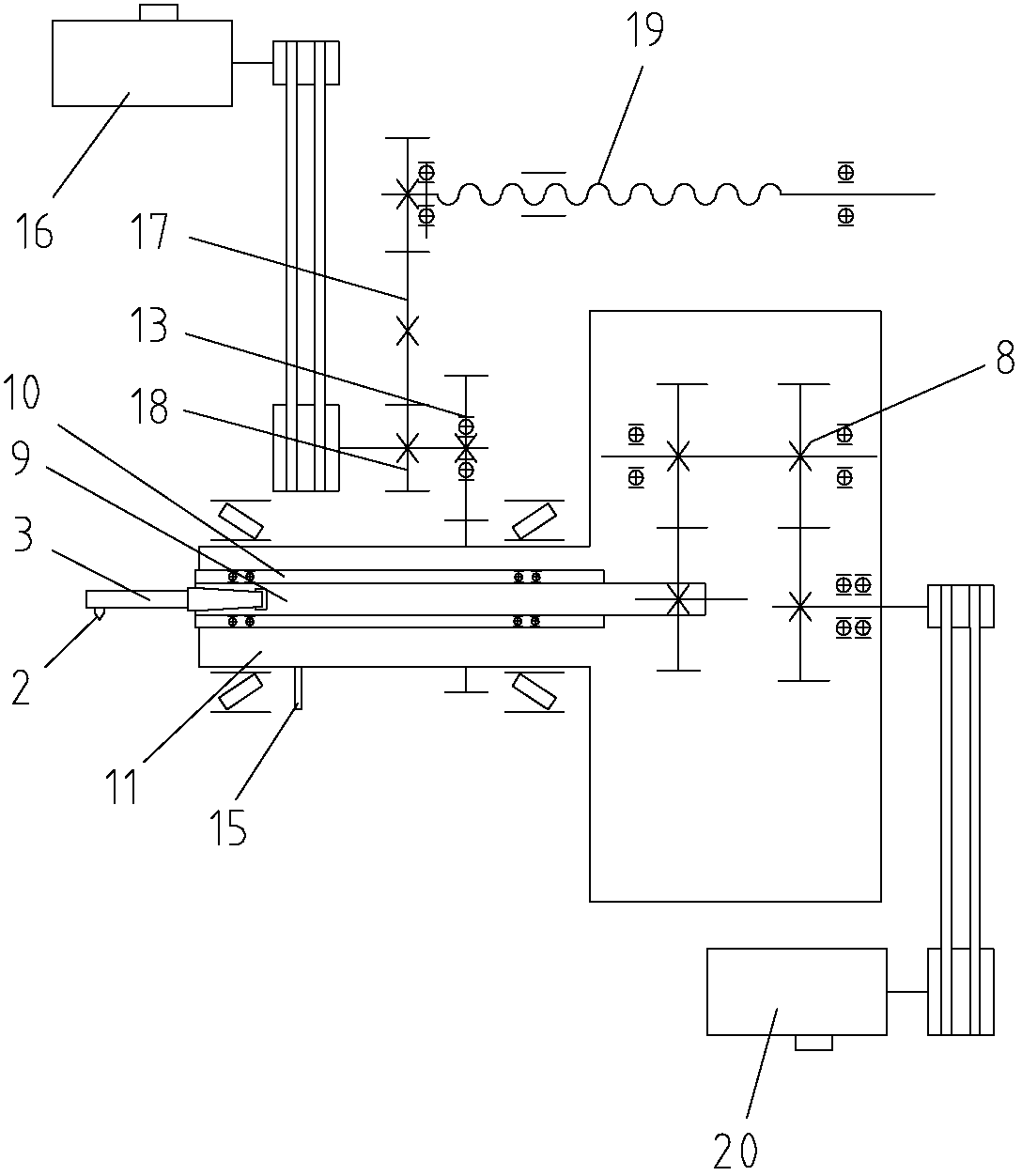

[0019] Refer to the attached drawings: this whirlwind thread cutting machine includes a worktable 4, a machine body 1 is provided on the worktable 4, a cutter bar 3 is provided on the machine body 1, and a milling cutter 2 is fixed on the end of the cutter bar 3, of which the cutter bar 3 Fixed on the axis of the autorotating main shaft 9, wherein the body 1 is provided with an eccentric shaft barrel 11 for installing the autorotating main shaft 9, wherein the autorotating main shaft 9 is installed at an eccentric position in the eccentric shaft barrel 11, and the rear end of the autorotating main shaft 9 passes through The eccentric shaft barrel 11 is connected with a rotation motor 20 through a gear box 8; wherein the eccentric shaft barrel 11 is connected with a revolution motor 16 that drives it to rotate; wherein a horizontal guide rail 5 is provided on the workbench 4, and a cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com