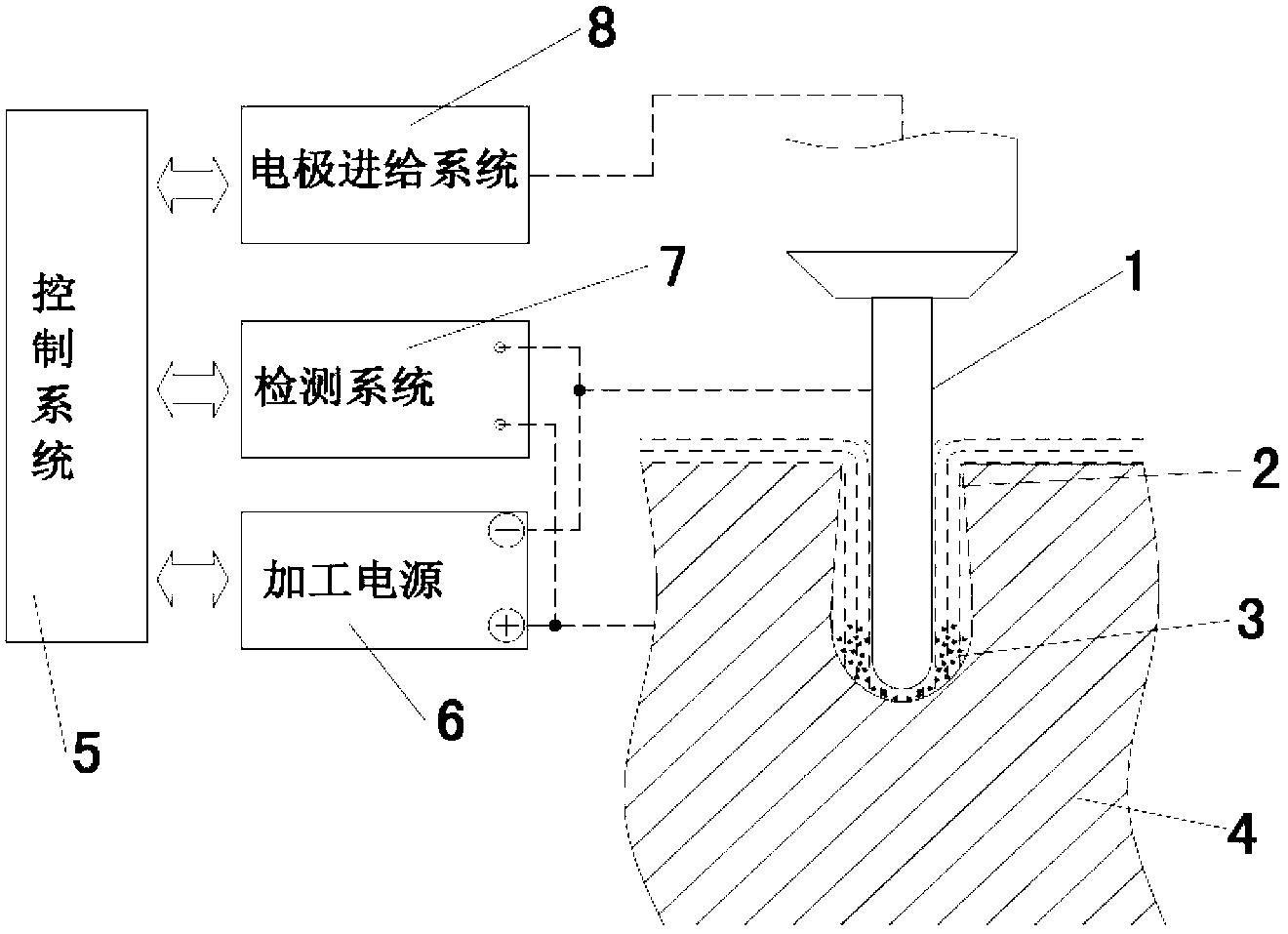

Electric spark machining method and device for micro inverted taper hole

A processing method and a technology for a reverse taper hole, which are applied in the field of electric discharge machining methods and processing devices, and can solve the problems of helpless taper, discharge energy reducing the feed speed, and small taper of the reverse taper hole.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

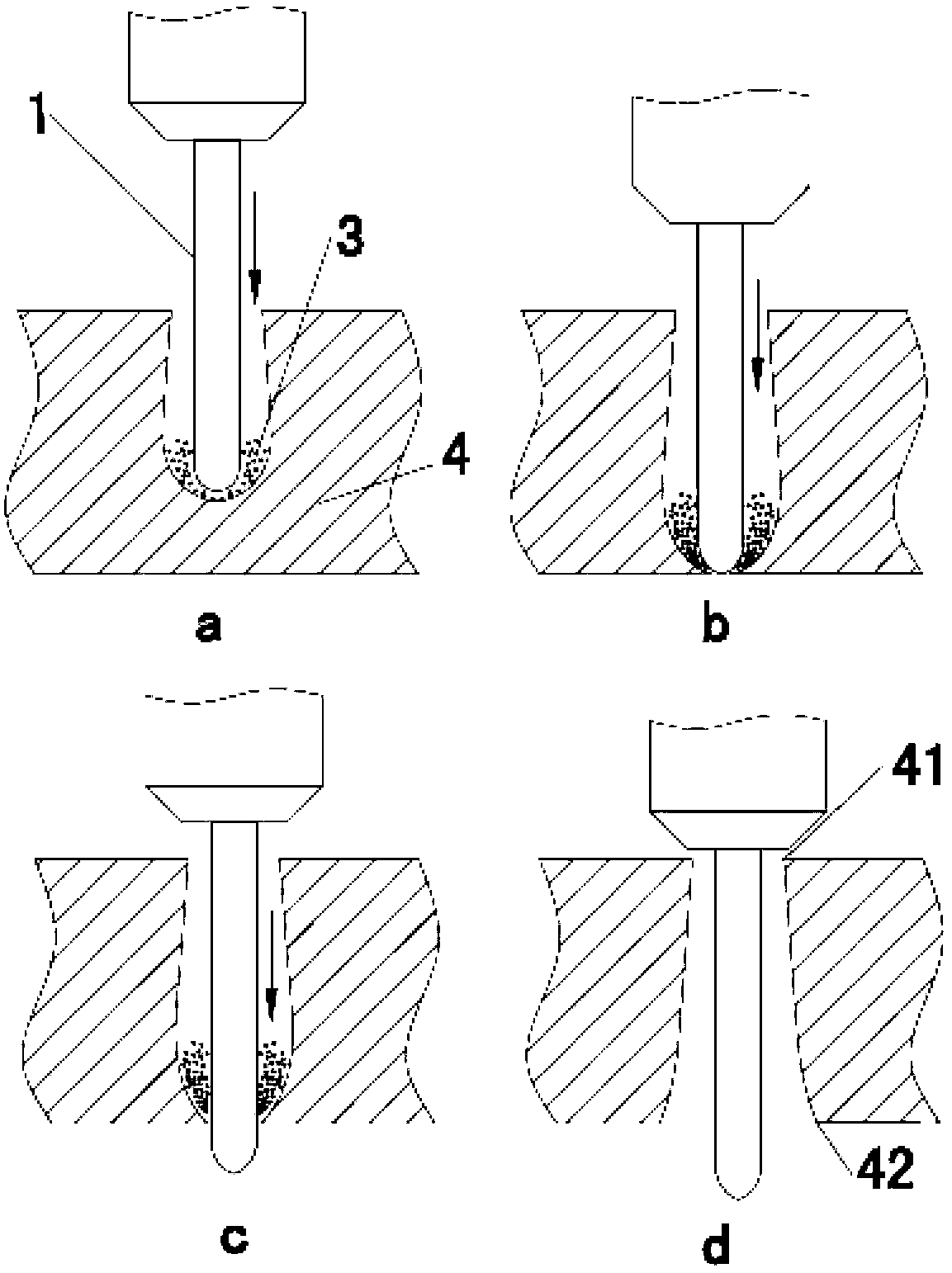

[0039] Example 1: Before the hole is machined through, the machining energy is not adjusted, and an inverted taper hole with a relatively small taper can be machined.

[0040] Such as figure 2 As shown in a to 2d, this embodiment includes the following steps:

[0041] 1) Turn on the processing power supply 6 and use the tool electrode 1 to process the workpiece 4. When the control system 5 judges that the hole has not been processed through, the processing energy of the processing power supply 6 remains unchanged. The control system 5 controls the electrode feeding system 8 according to the inter-electrode discharge state fed back by the detection system 7, and adjusts the gap between the tool electrode 1 and the workpiece 4 to achieve a good discharge state.

[0042] 2) When the control system 5 judges that the hole has been machined through, the control system 5 controls the electrode feed system 8 to make the tool electrode 1 feed rapidly, and at the same time increases t...

Embodiment 2

[0044] Embodiment 2: Before the hole is machined through, the discharge energy is gradually increased, and an inverted taper hole with a larger taper than that of Embodiment 1 can be processed.

[0045] Such as figure 2 As shown in a to 2d, this embodiment includes the following steps:

[0046] 1) Turn on the processing power supply 6, and use the tool electrode 1 to process the hole on the workpiece 4. When the control system 5 judges that the hole has not been processed through, the processing voltage of the processing power supply 6 increases gradually with the increase of the feed depth of the tool electrode 1. , at about the rear 1 / 3 of the feed depth of the tool electrode 1 before the hole is penetrated, the voltage is increased by 30% compared with the first 2 / 3. The control system 5 controls the electrode feeding system 8 according to the inter-electrode discharge state fed back by the detection system 7, and adjusts the gap between the tool electrode 1 and the workp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com