Normal-pressure infiltration catalytic separation structure of waste polyethylene (PE) strip steel corrugated pipe and technology for structure

A separate structure and bellows technology, applied in recycling technology, plastic recycling, etc., can solve the problems of reducing the utilization rate of plastics, affecting the quality of scrap steel, smelting pollution, etc., achieving low production costs, high production safety, and high thermal insulation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

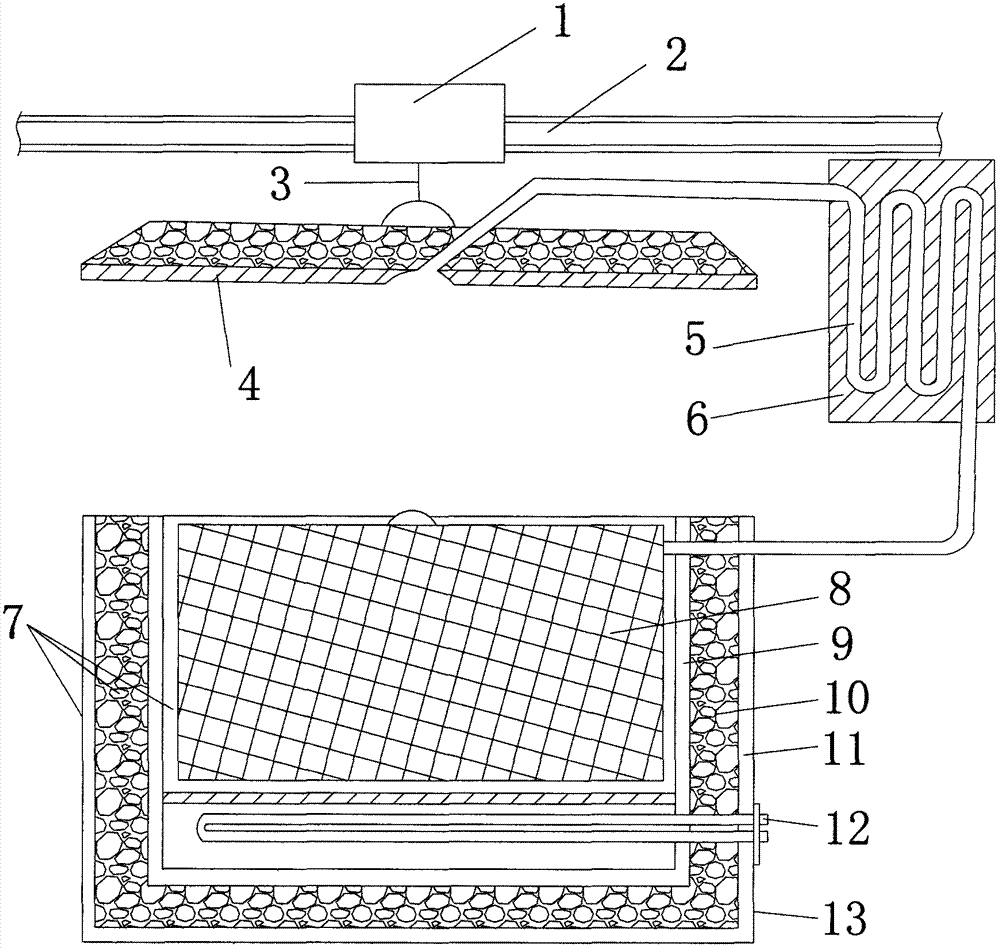

[0022] see figure 1 As shown, a kind of atmospheric pressure infiltration catalytic separation structure of waste PE strip steel bellows, which includes a reaction pot 7 and a reaction pot cover 4 and an electric heating tube 12 is installed in the reaction pot 7, and the reaction pot cover 4 passes through a hanging The rope 3 is connected with the electric hoist 1 arranged on a lifting bracket 2, and it also includes a steam cooling box 6 and a charging basket 8 for being hoisted into the reaction pot 7 by the electric hoist 1, and the steam cooling box 6 is provided with a steam discharge pipe 5, and the two ends of the steam discharge pipe 5 extend into the reaction pot 7 respectively. The reaction pot 7 is followed by an inner layer 9, a first outer layer 11, and a second outer layer 13 from the inside to the outside, and an ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com