Composite part and forming method thereof

A technology for composite materials and parts, applied in the field of composite material processing and forming, can solve the problems of misalignment between layers and low strength of composite parts, reduce air bubbles and dry spots, increase shear strength, and resist compression and bending Effects of Strength, Rigidity, and Reliability Improvements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

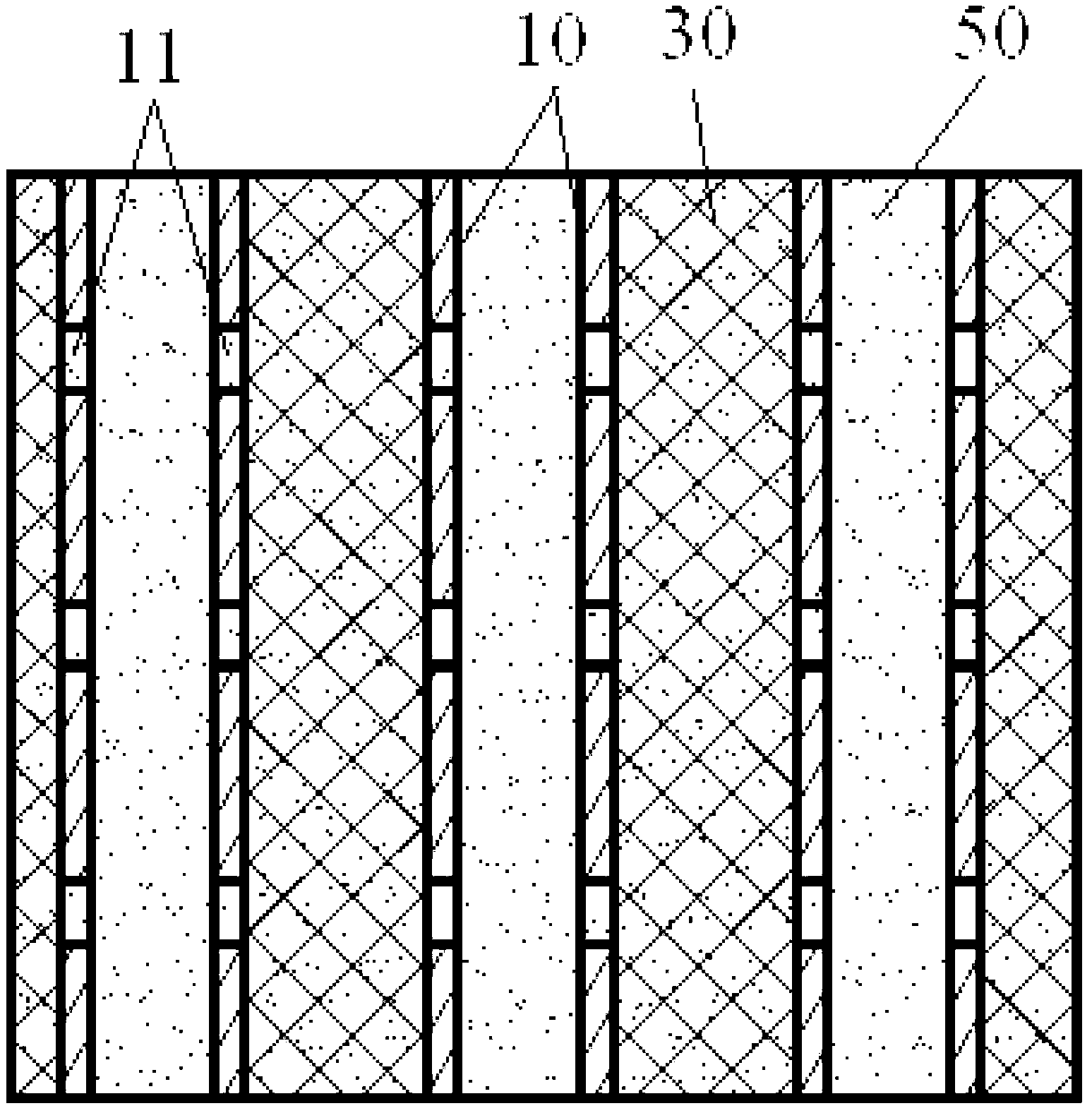

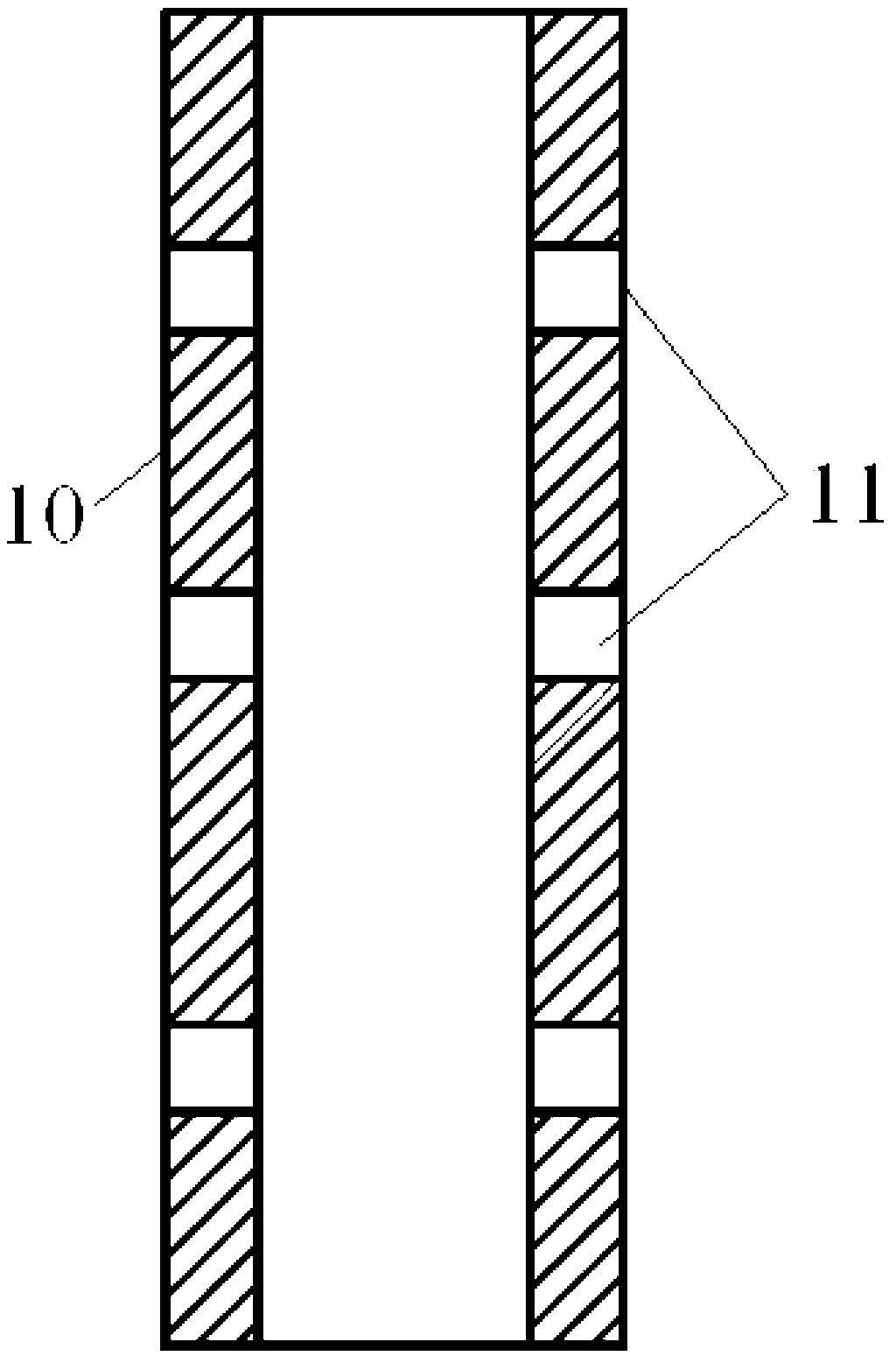

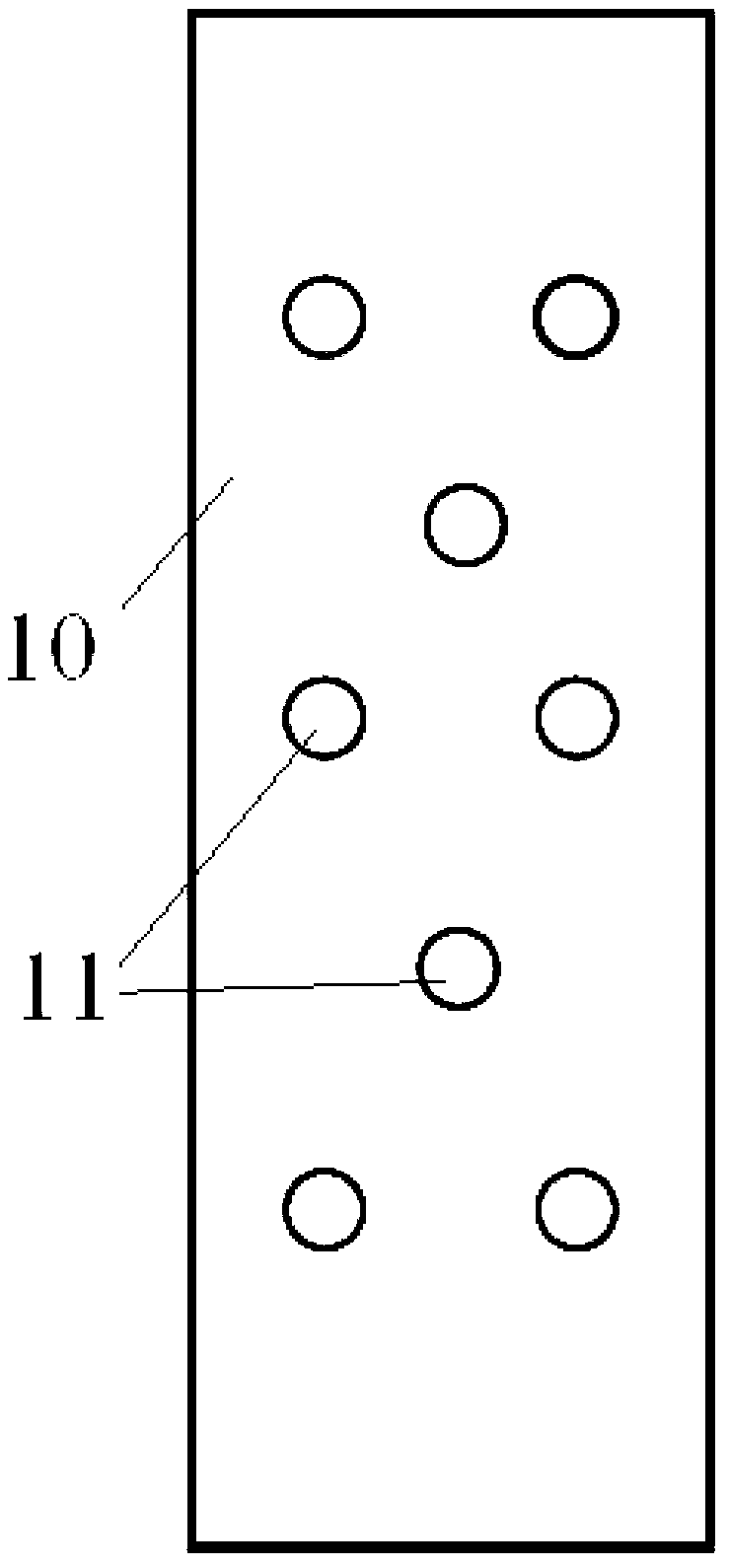

[0026] Such as figure 1 As shown, according to one aspect of the present invention, a composite material product is provided, including: a plurality of supporting frame parts 10, these supporting frame parts 10 are arranged according to the shape of the composite material part; braided fibers 30 are arranged layer by layer Between the outer surfaces of the supporting skeleton parts 10 and together with these supporting skeleton parts 10, a prefabricated part matching the shape of the composite material part is formed; the casting matrix 50 is impregnated in the prefabricated part and formed integrally with the prefabricated part after being cured Composite parts.

[0027] In the composite material part that the present invention provides, adopt a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com