Manufacturing method of ultra coarse-grain tungsten carbide powder

A technology of tungsten carbide powder and manufacturing method, which is applied in the direction of carbide, tungsten/molybdenum carbide, etc., can solve the problem of not being able to meet the requirements for the production and application of ultra-coarse-grained or ultra-coarse-grained hard alloys, and inherit the quality of original tungsten powder Defects, increased content of harmful impurities such as iron, etc., to achieve the effect of favorable growth and perfection, perfect crystal development, and low content of harmful impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Preferred embodiment of the present invention.

[0017] First, mix and stir the ultra-coarse crystalline tungsten powder in the carbon dispenser, which is a "mixer for preparing tungsten carbide powder" with the patent number of 03253385.3; then mix the tungsten-carbon with carbon The material is sent to the carbonization equipment, which is heated by medium frequency induction to carry out ultra-high temperature carbonization above 2200 °C.

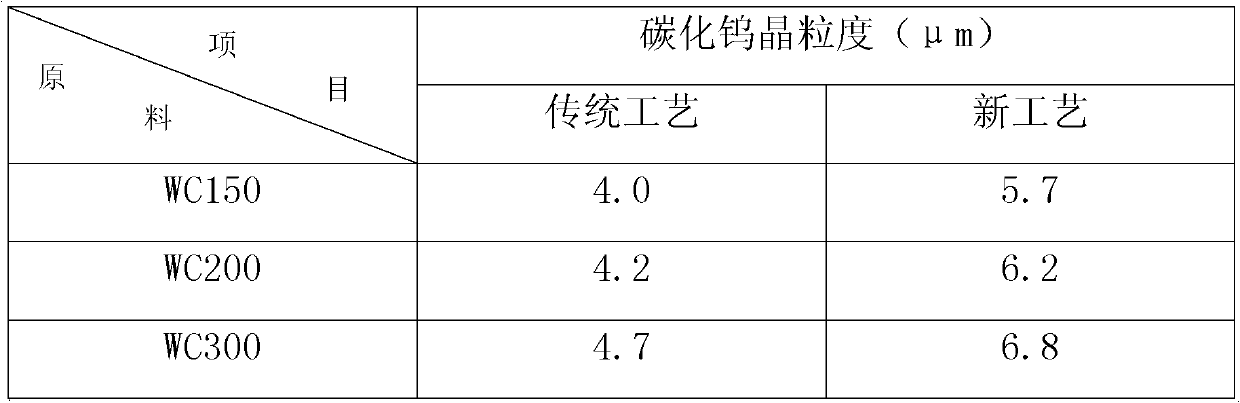

[0018] The following is a comparison of the grain size of tungsten carbide powder raw materials with different grain sizes, and the ultra-coarse grain tungsten carbide powder produced by the traditional process and the process of the present invention.

[0019]

[0020] It can be seen from the table that the process of the present invention makes the crystal development perfect, and the grain size of the tungsten carbide powder is greatly increased, exceeding 5.5 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com