Method for removing organic matters and metal ions from mineral raw water in five connective lakes

A technology of Wudalianchi and metal ions, applied in chemical instruments and methods, non-metallic elements, adsorption water/sewage treatment, etc., can solve the problems of complicated process, unable to reduce Wudalianchi mineral water, high cost of water treatment process, etc., and achieve simple treatment method , Reduce processing costs, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0006] Specific implementation mode one: the present implementation mode is a kind of removal method of organic matter and metal ion in the raw water of Wudalianchi mineral water, specifically completes according to the following steps:

[0007] 1. Treatment of volcanic rocks: first, clean the volcanic rocks with deionized water, then dry them at a temperature of 100°C to 110°C for 9h to 24h, cool to room temperature to crush the volcanic rocks, and obtain 0.1cm-diameter particles through sieving. 1.0cm volcanic rock fragments, and then burn 0.1cm-1.0cm diameter volcanic rock fragments at a temperature of 750°C to 850°C for 150min to 250min, and place them in a desiccator to cool to room temperature after burning. Then soak in hydrochloric acid with a concentration of 5mol / L-10mol / L for 10min-15min, take out the treated volcanic rock and dry it, and then soak it in a sodium hydroxide solution with a concentration of 10mol / L-20mol / L for 10min-15min , take it out and dry it to c...

specific Embodiment approach 2

[0008] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, the volcanic stone is first cleaned with deionized water, then dried at a temperature of 102°C to 108°C for 12h to 20h, and cooled to room temperature Crush the volcanic rock, and obtain volcanic rock fragments with a diameter of 0.2cm to 0.9cm through sieving, and then burn the volcanic stone fragments with a diameter of 0.2cm to 0.9cm at a temperature of 780°C to 820°C for 180min to 220min, after burning, place it in a desiccator to cool to room temperature, then soak in hydrochloric acid with a concentration of 6mol / ~8mol / L for 12min~14min, take out the treated volcanic rock and dry it, and then put it in a concentration of 12mol / L Soak in ~18mol / L sodium hydroxide solution for 12min~14min, take it out and dry it to constant weight at a temperature of 102°C~108°C to obtain the treated volcanic rock. Others are the same as the first embodiment.

specific Embodiment approach 3

[0009] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the volume ratio of the processed volcanic rock described in step 2 and the raw water of Wudalianchi mineral water is (1.2~1.4):1. Others are the same as those in Embodiment 1 or 2.

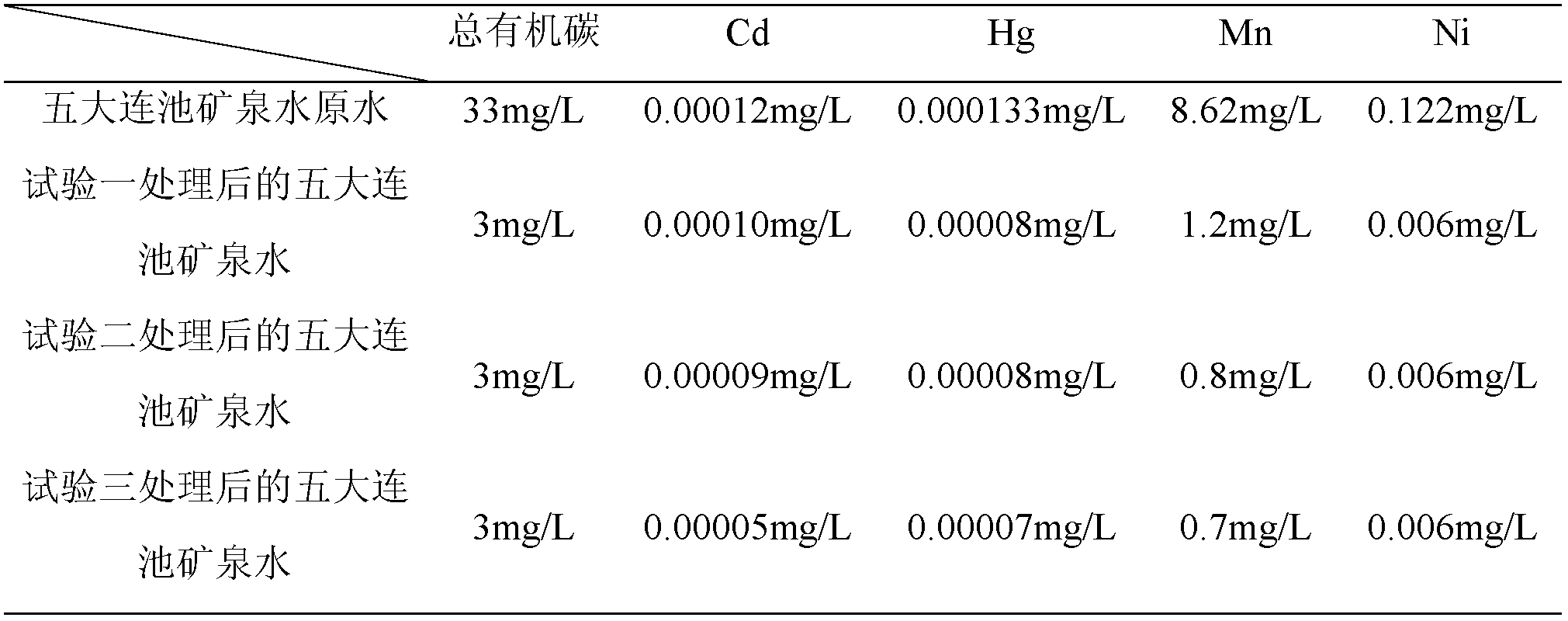

[0010] Adopt following test to verify effect of the present invention:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com