Cement-based steel slag granite product and preparation method thereof

A granite and cement-based technology, applied in the field of building materials, can solve the problems of low hardness, easy yellowing and discoloration of marble surface, and resistance to scratching, etc., to improve surface wear resistance and mechanical properties, increase added value, overcome The effect of poor weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4-5

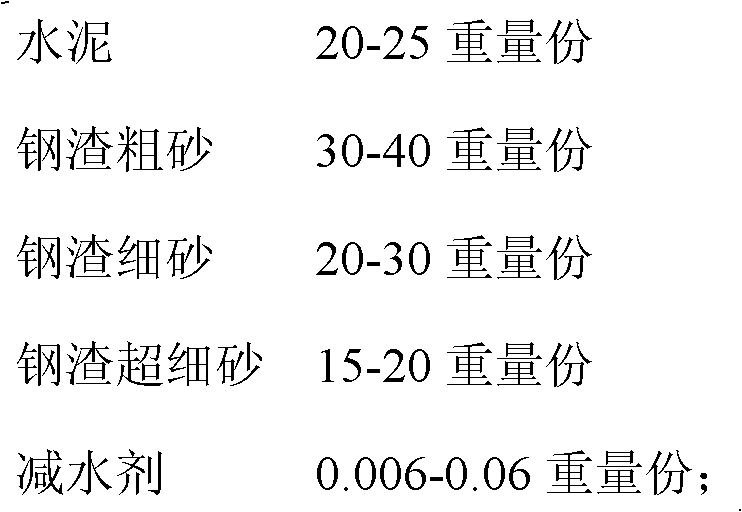

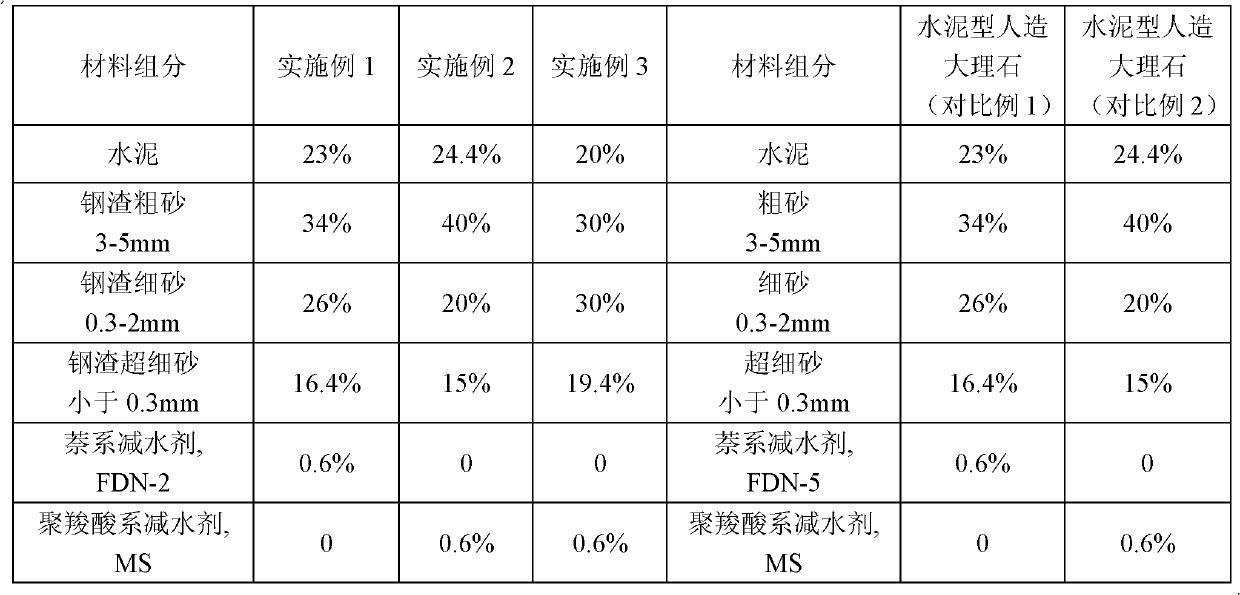

[0054] The raw material components and ratios of Examples 4-5 are shown in Table 4, and the values in the table are all mass percentages.

[0055] The raw material formula of each embodiment of table 4

[0056]

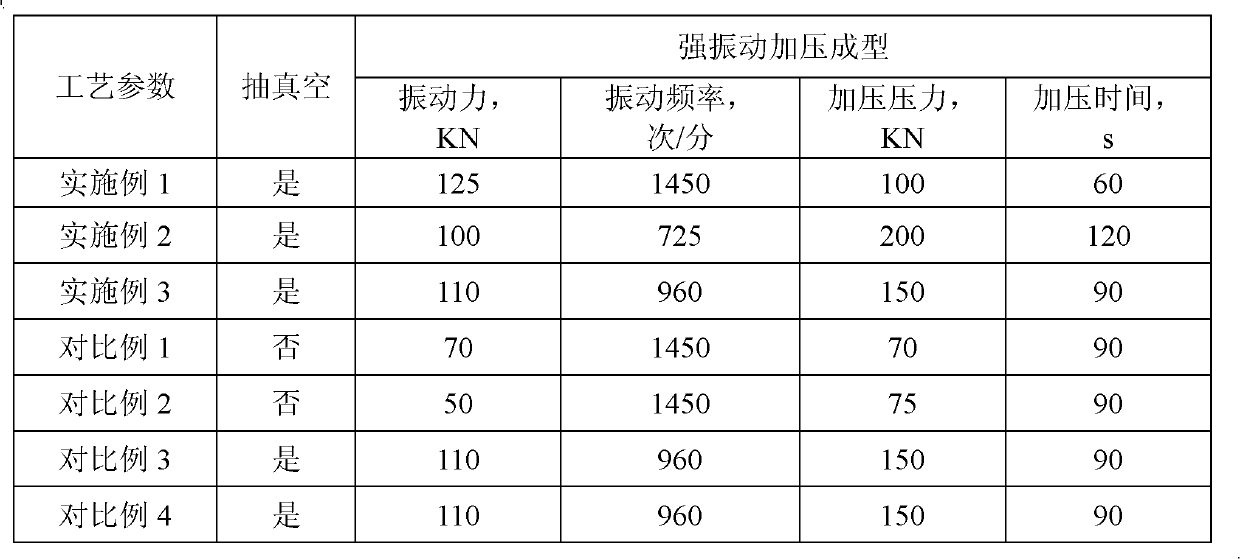

[0057] In addition to the difference in raw material components, the above-mentioned comparative examples and the examples are also different in their preparation methods. The difference is that the comparative examples adopt a weak vibration press molding process, while the present invention adopts a strong vibration press process. Concrete process parameter is as shown in table 5:

[0058] Table 5 Molding Process Parameters

[0059]

[0060] The test properties of the finished products obtained in the above examples are as follows: the test method is carried out in SN / T0308-1993 "Export Artificial Stone Test Method".

[0061] Table 6 performance test results

[0062]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com