Method for separating amygdalin from almond oil residue

A technology of amygdalin and almond oil, applied in the field of separation of amygdalin, can solve the problems of not considering the removal of oil and protein impurities, increasing production costs, affecting product quality, etc., and achieves easy industrial production, saving production costs and prices cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

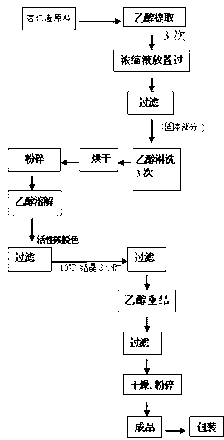

Image

Examples

Embodiment 1

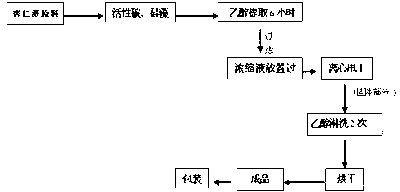

[0026] refer to figure 2 Shown, a kind of method for separating amygdalin from almond oil residue, carries out by following steps successively:

[0027] (1) Mixing material: crush the almond oil residue to 100 mesh, add 0.4-0.6 times the amount of activated carbon and 0.4-0.6 times the amount of diatomite to the total weight of the almond oil residue according to the mass ratio, and mix well Stir well and set aside;

[0028] (2) Extraction: Put the fully mixed and evenly stirred raw materials into the extraction equipment, heat to 72°C-78°C with 5 times the amount (weight / volume) of ethanol, and extract for 6-7 hours;

[0029] (3) Filtration and crystallization: The extracted liquid is directly filtered with a plate-and-frame filter and a 0.2-micron membrane while it is hot, and placed in a clean container to stand overnight;

[0030] (4) Centrifugal drying: After overnight crystallization of the mixed solution, pour it directly into a centrifugal dryer to dry, and directly...

Embodiment 2

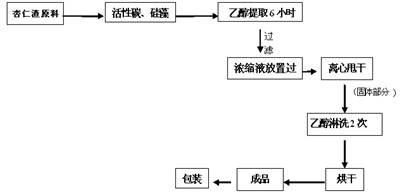

[0034] According to the mass ratio, take 1.5 kg of raw materials, mix them with 0.75 kg of activated carbon and 0.75 kg of diatomaceous earth, mix them evenly, put them in a 20L jar, add 7.5L of ethanol, heat at 75°C for 6 hours, filter the extract with a 0.2 micron membrane and leave it overnight , and carried out crystallization and suction filtration according to the inventive process, and dried at a temperature of 75° C. for 24 hours to obtain 45.3 grams of the product, the content detection was 98.33%, and the yield was 75.42%.

Embodiment 3

[0036] According to the mass ratio, take 10 kg of the same batch of raw materials, mix them with 5 kg of activated carbon and 5 kg of diatomaceous earth, mix them evenly, put them in a 200L extraction tank, add 50L of ethanol and heat at 75°C for 6 hours, and filter the extract with a 0.2 micron membrane and place it Overnight, crystallization and suction filtration were carried out according to the inventive process, and 305 grams of the product were obtained after drying at a temperature of 75° C. for 24 hours. The content was detected to be 99.13%, and the yield was 76.25%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com