Protein microdialyzer and usage method

A dialysis device and protein technology, applied in the experimental field of protein purification, can solve the problems of difficult protein recovery, small volume, leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

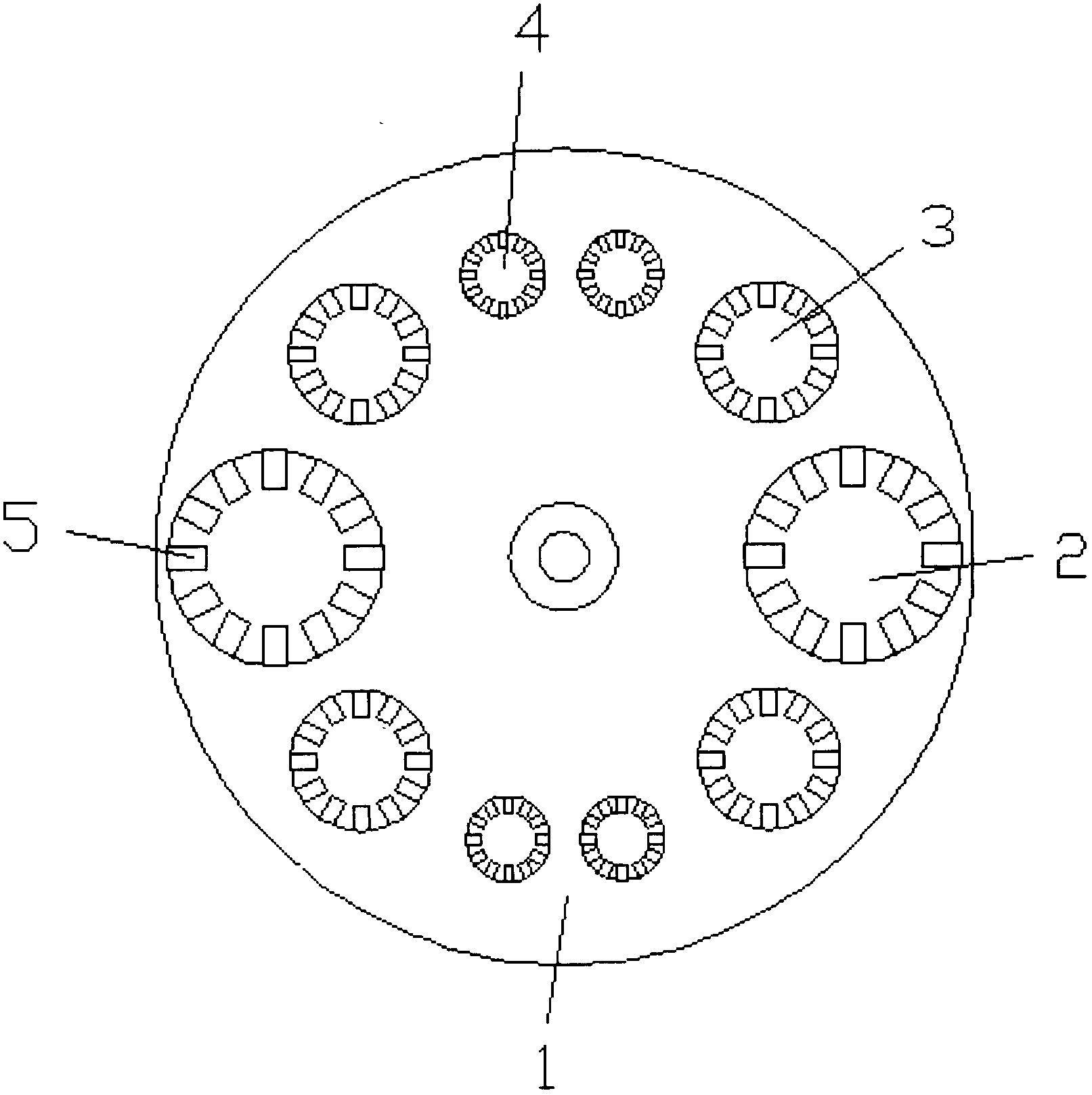

[0024] Embodiment 1, the structural composition of microdialysis device

[0025] The microdialysis device includes the following components: microdialysis tubing assembly, semipermeable membrane, rubber ring, floating plate and magnetic stirring bar.

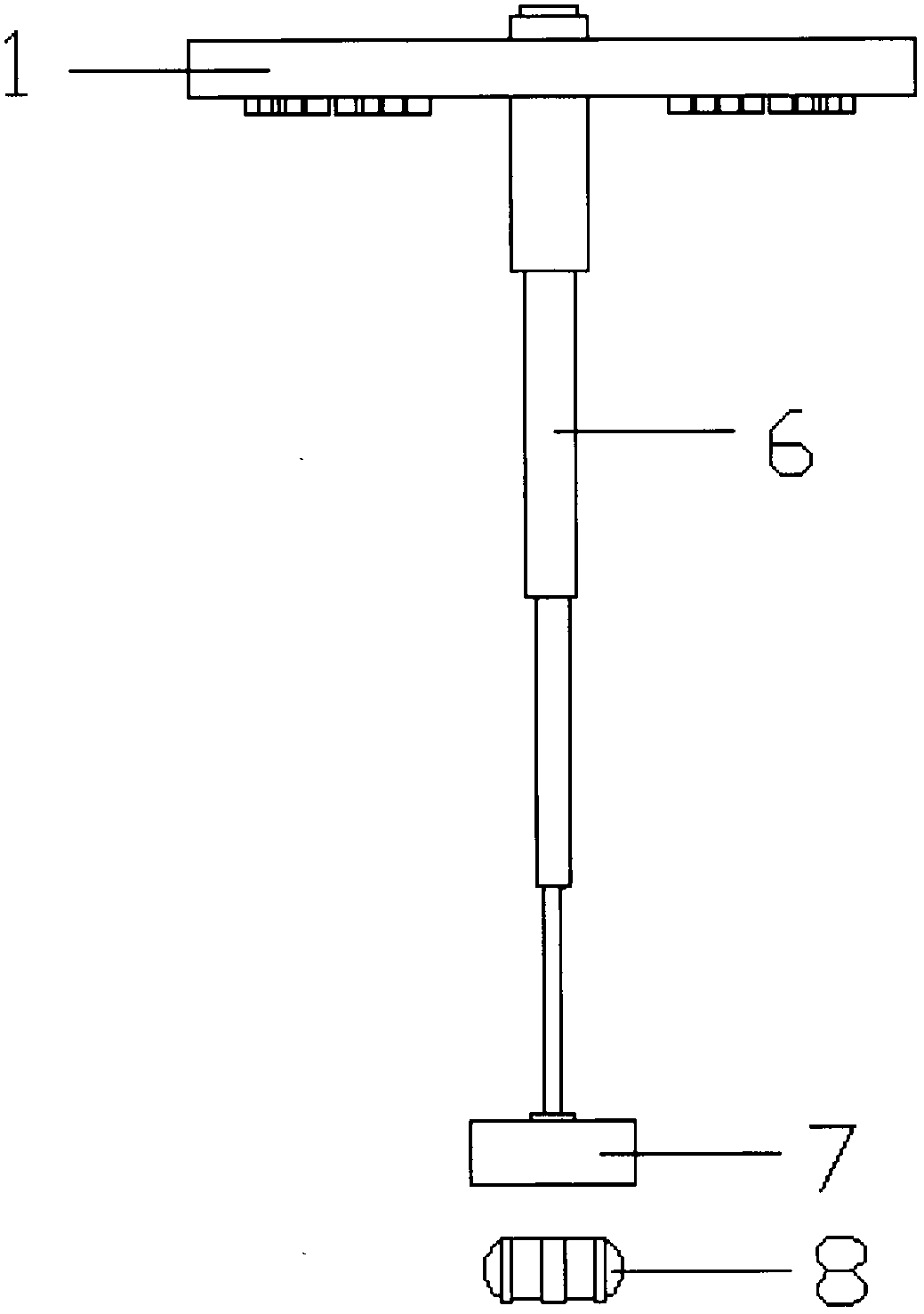

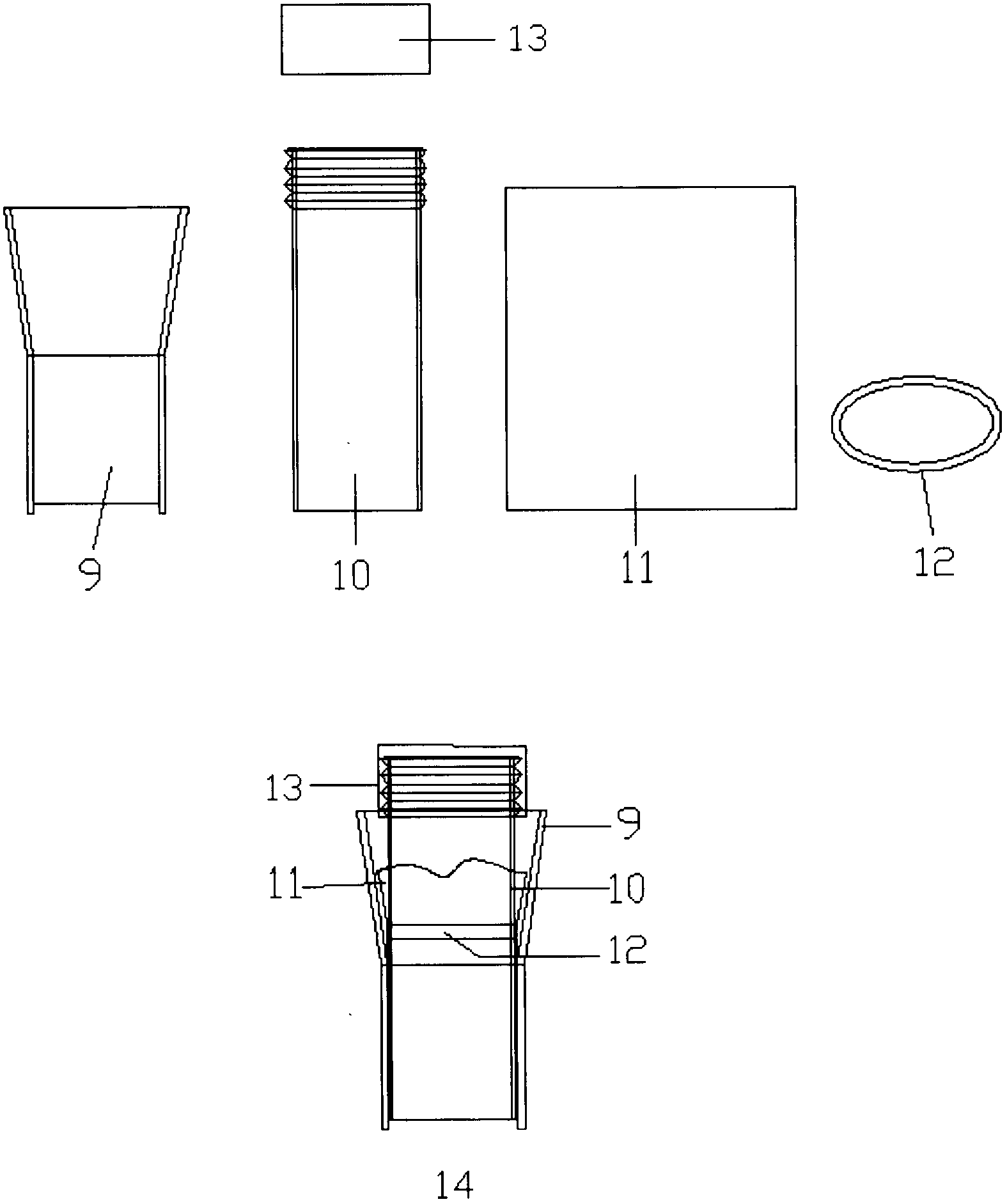

[0026] (1) The microdialysis tubing assembly includes three types of I, II, and III, which are composed of the following parts: the outer casing (the inner diameter φ is respectively: Type I 17.0mm, Type II 11.0mm, Type III 8.0mm, height h 30.0mm), the inner sleeves (outer diameters φ respectively: Type I 16.7mm, Type II 10.7mm, Type III 7.7mm, height h 38.0mm) compatible with the outer sleeve, and various types of inner sleeves Caps that fit the tubes.

[0027] (2) The square semipermeable membrane (side length l: 50.0mm, mesh: 5500-30000MW) pretreated in the laboratory, and the rubber ring (diameter smaller than the inner sleeve) for fixing the semipermeable membrane.

[0028] (3) Floating plates with different apertures. Th...

Embodiment 2

[0031] Embodiment 2, the using method of microdialysis device

[0032](1) Select the inner sleeves of two Type I microdialysis tubes, pick up two semi-permeable membranes, wrap the bottom of each inner sleeve respectively, insert the rubber ring from bottom to top, and tightly seal the semi-permeable membranes. Bind to the outer wall of the inner cannula, pay attention to the fact that the semipermeable membrane surface at the bottom of the inner cannula must be flat and there is no air bubbles at the proximal end of the inner cannula.

[0033] (2) Insert the two inner casings with semipermeable membranes into the corresponding outer casings, and plug them tightly so that the bottom does not leak. In order to check whether the semipermeable membranes are tight and complete, you can add a small amount of buffer from the upper part of the dialysis tubing and observe There is no seepage of liquid from the bottom of the membrane.

[0034] (3) Place the cannula on a clean table, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

| Maximum stretch length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com