Decorative putty and preparation method thereof

A decorative putty technology, applied in the direction of filling slurry, etc., can solve the problems of bond strength, water resistance, poor decoration effect, etc., and achieve good low-temperature storage performance, material saving, and good hand feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

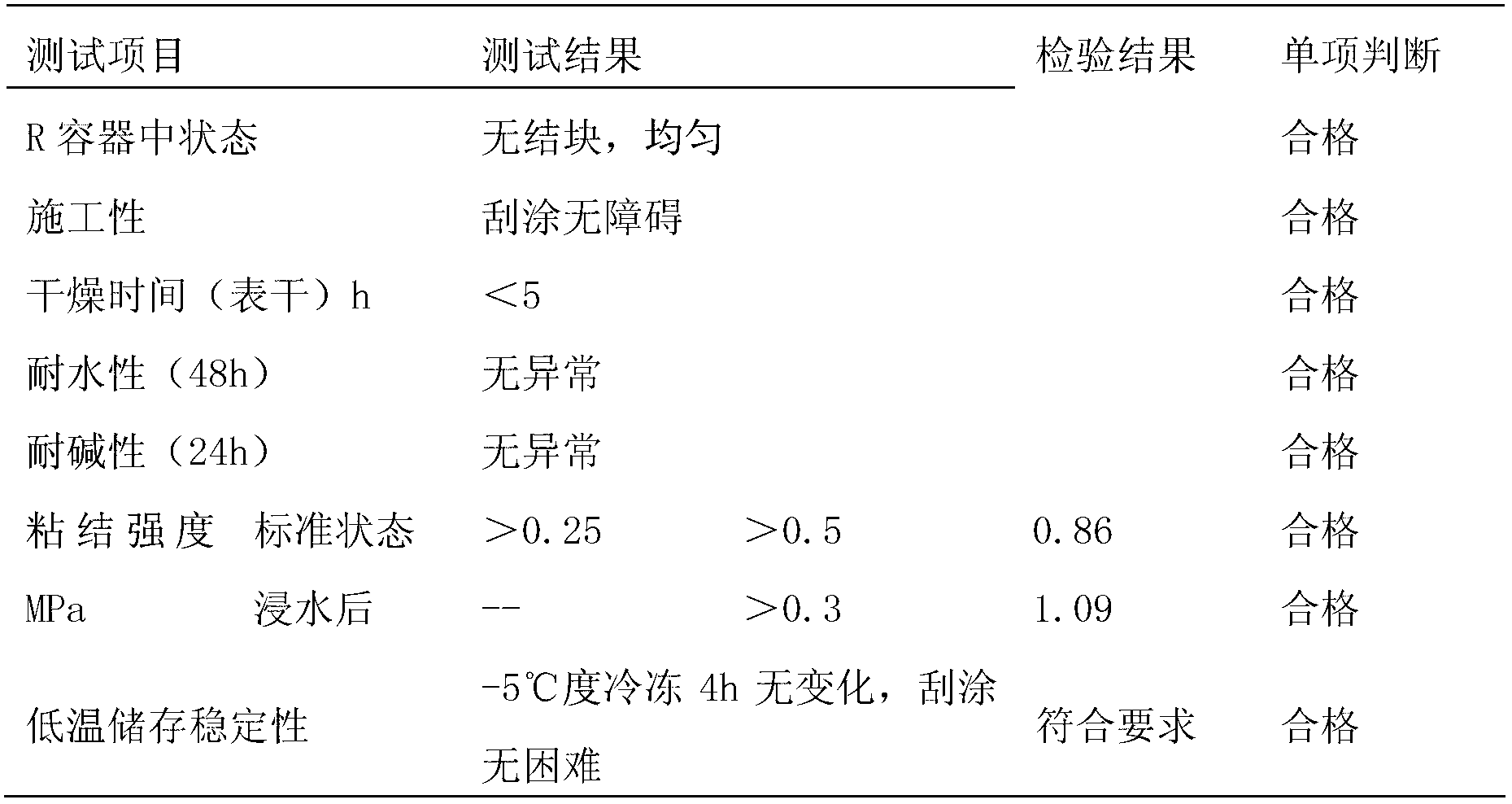

Embodiment 1

[0032] A kind of decorative putty for building interior walls, in terms of mass percentage, the decorative putty is composed of 35% of component A and 65% of component B; wherein the mass percentage formula of component A and component B is as follows:

[0033] Component A

[0034] Cellulose 4.5%

[0035] water 70%

[0036] Strong Base Sodium Hydroxide 18.5%

[0037] Glycerol 2%

[0038] Calcium halophosphate phosphor 1%

[0039] Water resistant agent 2%

[0040] The water resistant agent is Titan D-66, purchased from Qingdao Titan Trading Co., Ltd.

[0041] The cellulose is selected from carboxymethylcellulose sodium salt (CMC) cellulose.

[0042] Component B

[0043] Calcium carbonate 75% and talcum powder 25% (by mass percentage)

[0044] A preparation method of decorative putty, comprising the steps of:

[0045] (1) Weigh the components of component A according to the formula, mix them evenly, and react at room temperature for 24 hours to form a gel;

[0046] (2)...

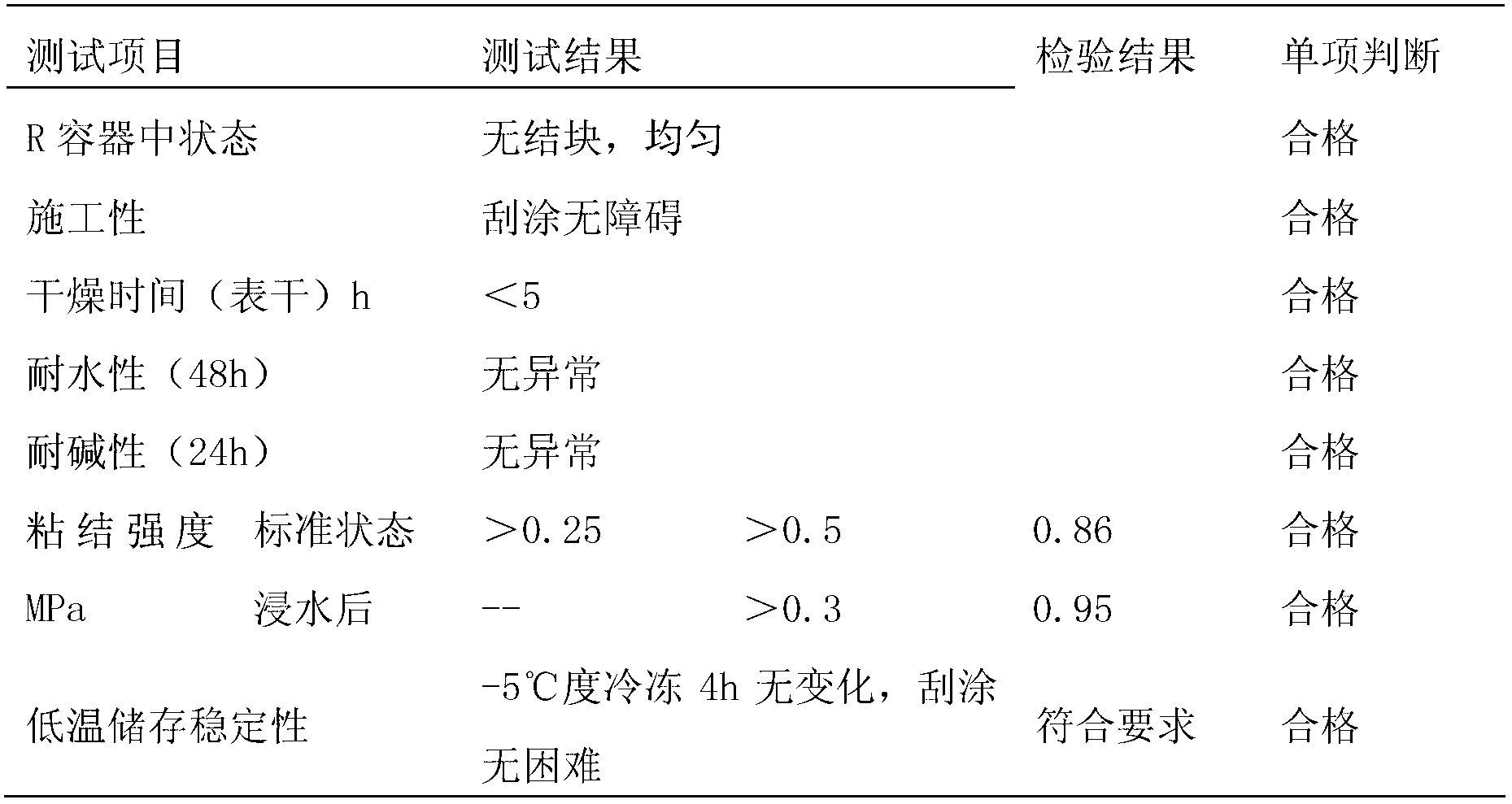

Embodiment 2

[0053] A kind of decorative putty for interior walls of buildings. In terms of mass percentage, the decorative putty is composed of 30% of component A and 70% of component B; wherein the mass percentage formula of component A and component B is as follows:

[0054] Component A

[0055] Cellulose 6%

[0056] water 75%

[0058] Glycerol 1.%

[0059] Calcium halophosphate phosphor 2%

[0060] Water resistant agent 0.5%

[0061] The water resistant agent is Titan D-66, purchased from Qingdao Titan Trading Co., Ltd.

[0062] The cellulose is methyl cellulose (MC).

[0063] Component B

[0064] Calcium carbonate 70% and talcum powder 30% by mass percentage.

[0065] A preparation method of decorative putty, comprising the steps of:

[0066] (1) Weigh the components of component A according to the formula, mix them evenly, and react at room temperature for 24 hours to form a gel;

[0067] (2) Weigh each component of component B according to the...

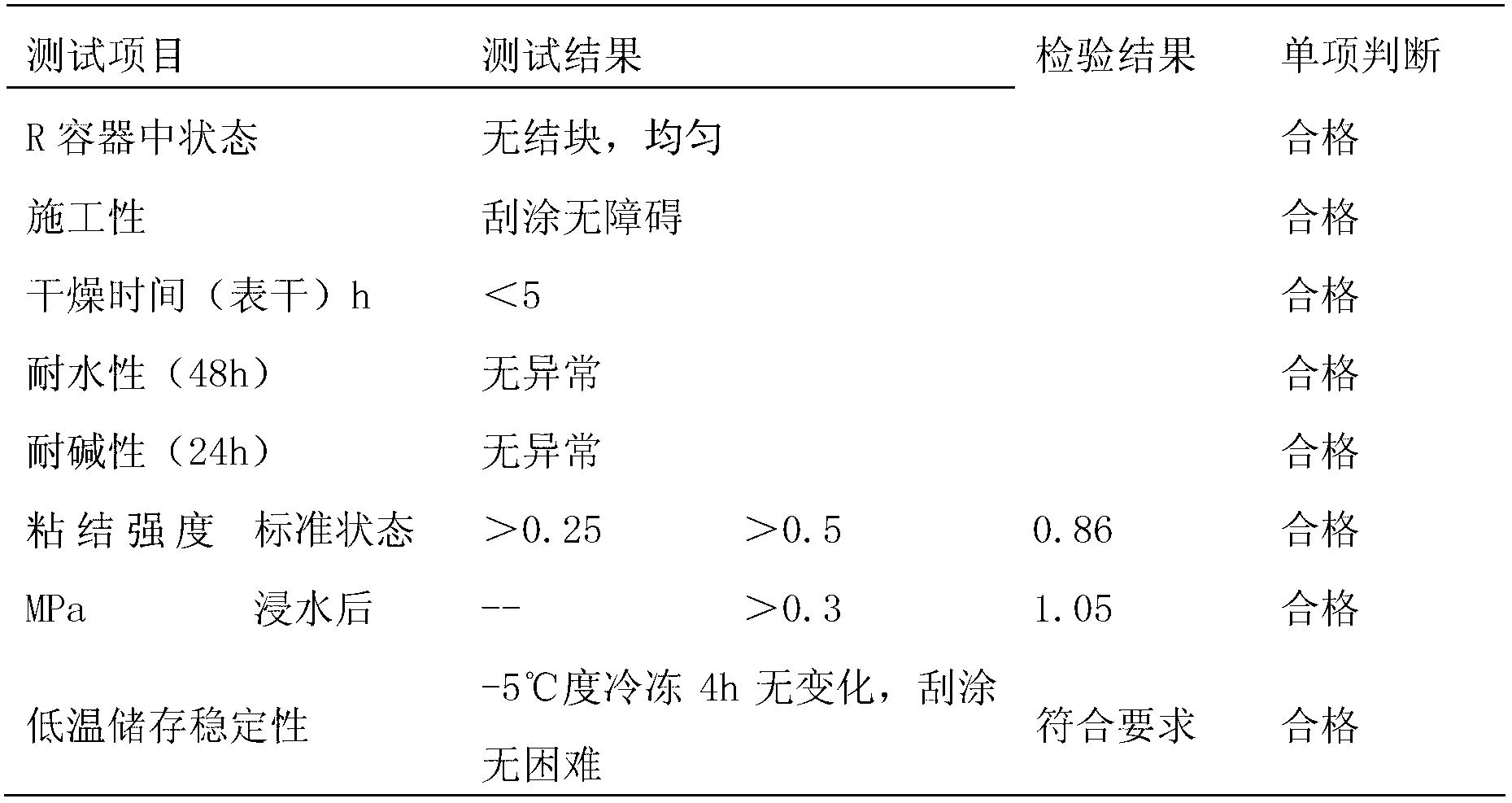

Embodiment 3

[0074] A kind of decorative putty for interior walls of buildings. In terms of mass percentage, the decorative putty is composed of 40% of component A and 60% of component B; wherein the mass percentage formula of component A and component B is as follows:

[0075] Component A

[0076] Cellulose 3%

[0077] Water 74%

[0079] Glycerol 2%

[0080] Calcium halophosphate phosphor 0.5%

[0081] Water resistant agent 0.5%

[0082] The water resistant agent is Titan D-66, purchased from Qingdao Titan Trading Co., Ltd.

[0083] The cellulose is methyl cellulose (MC).

[0084] Component B

[0085] Calcium carbonate 80% and talcum powder 20% by mass percentage.

[0086] A preparation method of decorative putty, comprising the steps of:

[0087] (1) Weigh the components of component A according to the formula, mix them evenly, and react at room temperature for 24 hours to form a gel;

[0088] (2) Weigh each component of component B according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com