Central jet flow centrifugal washing machine

A central jet, washing machine technology, applied in washing machines with containers, washing devices, textiles and papermaking, etc., can solve the problems of inability to complete laundry tasks, jet washing machines not drying clothes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

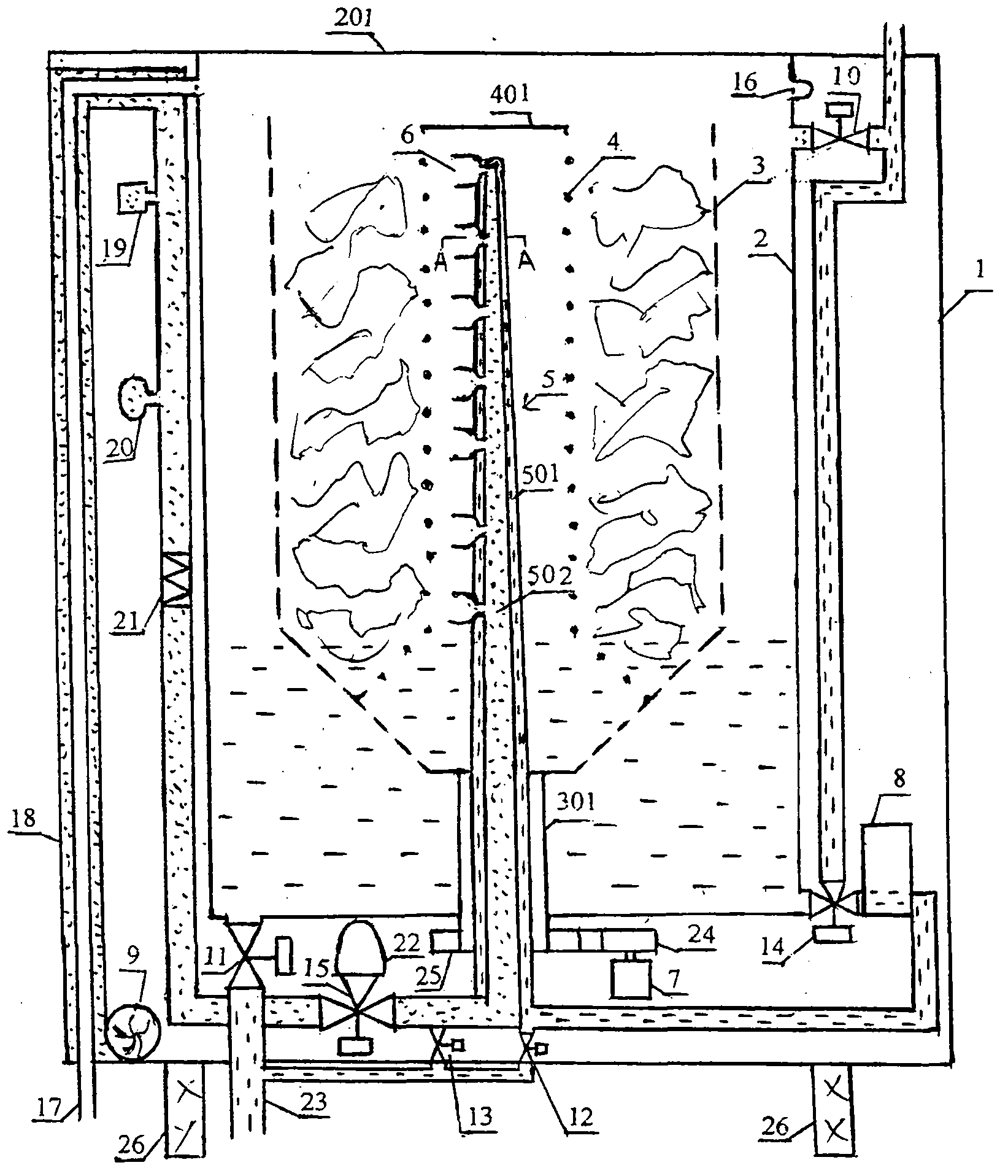

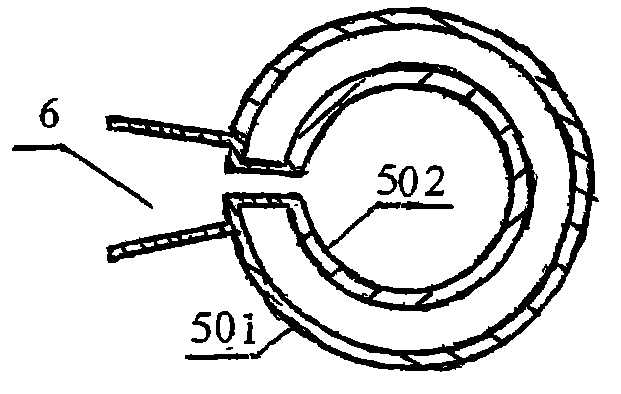

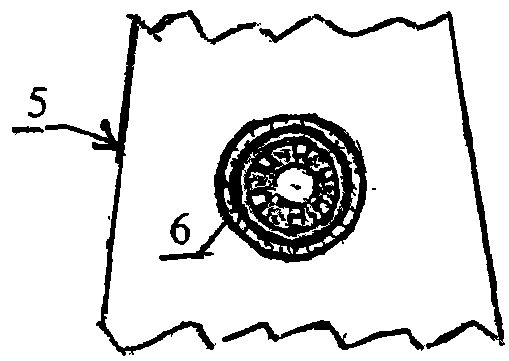

[0011] figure 1 , figure 2 , image 3 , Figure 4Shown: the center jet centrifugal washing machine of the present invention, it is mainly made of casing 1, outer barrel 2, inner barrel 3, seepage barrel 4, outer barrel cover 201, motor 7, water pump 8, hollow rotating shaft 5, water inlet electromagnetic valve 10, main drainage Solenoid valve 11 and electrical control system are formed. The order of its structure from the outside to the inside is: shell 1, outer barrel 2, inner barrel 3, seepage barrel 4, and a frustum-shaped hollow rotating shaft 5 with a small upper part and a larger lower part is erected in the central position. There is an outer barrel cover 201 to cover the bung of the outer barrel 2, and the drain outlet of the outer barrel 2 bottoms is provided with a main drainage electromagnetic valve 11, and the outlet of the main drain electromagnetic valve 11 is equipped with a drainpipe 23. There are many small holes on the inner barrel 3, and the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com