Construction method for processing ultra-thick quicksand layer of pile foundation by using front-end vibration steel casing

A construction method and technology of steel casings, which are applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of easily damaged stratum structures and low construction efficiency, and achieve high construction efficiency, convenient installation and dismantling, and lower requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

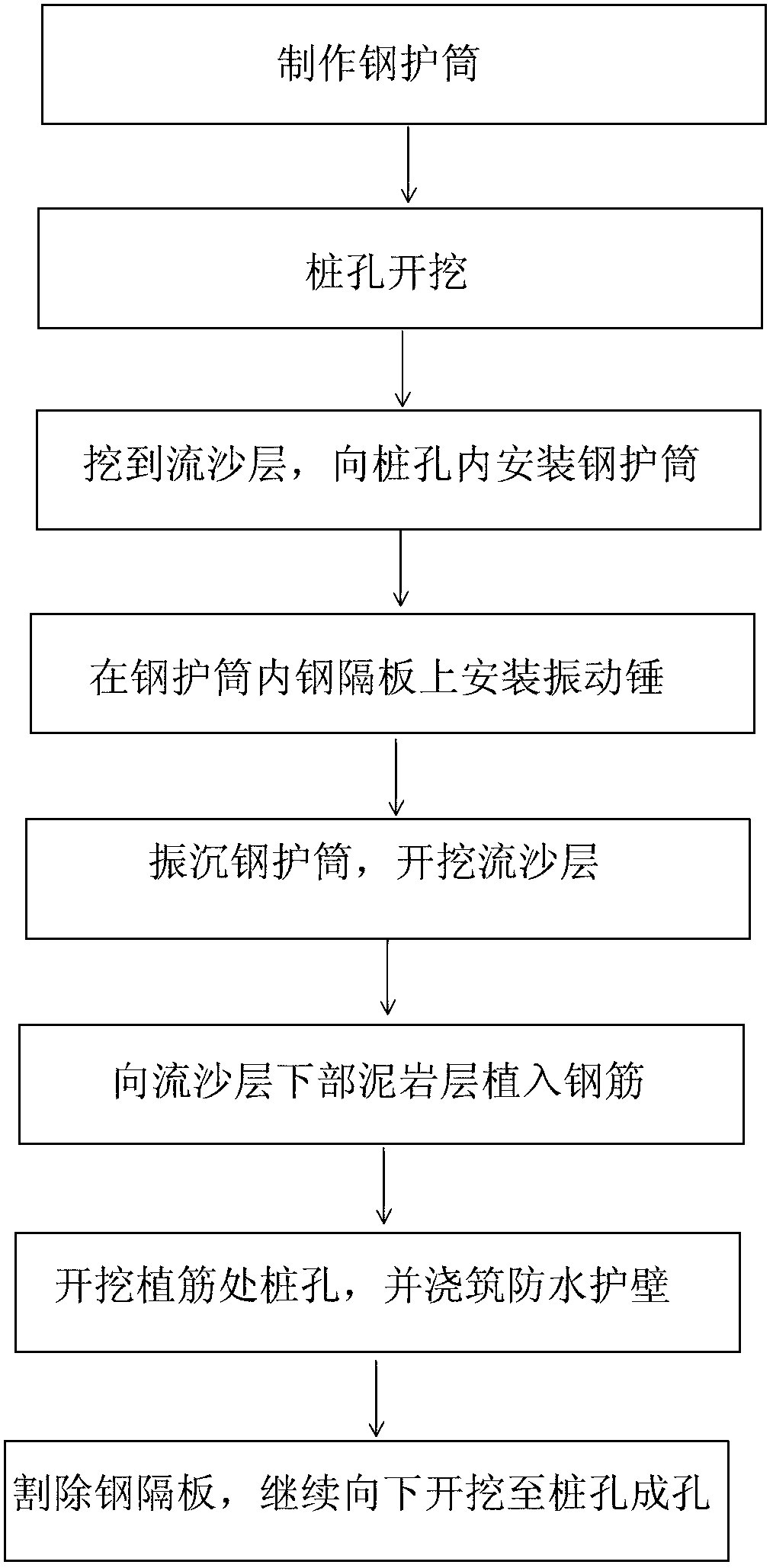

[0031] figure 1 It is a construction flow chart of the construction method of the front-end vibrating steel casing of the present invention for processing the ultra-thick quicksand layer of the pile foundation, including the following steps:

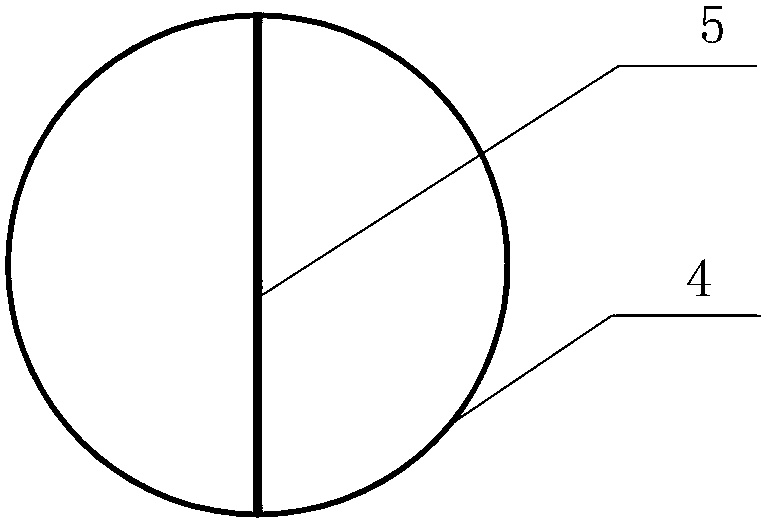

[0032] (1) Make vibrating steel casing: select a steel casing whose inner diameter is more than 6cm larger than the designed pile diameter, and weld a steel partition along the axial direction of the steel casing inside the steel casing, the plane of the steel partition and the steel casing The axes are parallel; the center of the steel partition is located on the axis of the steel casing;

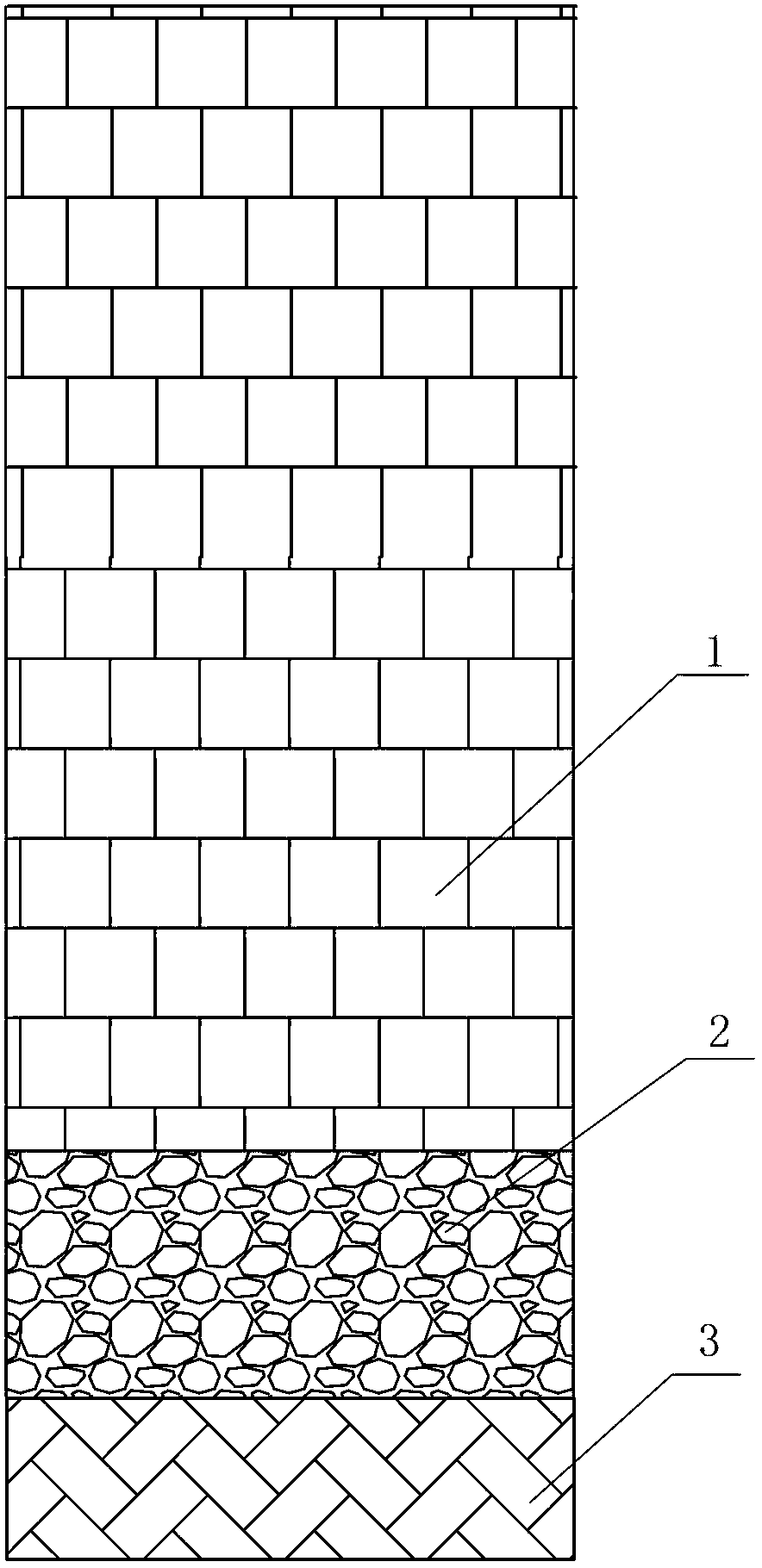

[0033] (2) Excavate the non-quick sand layer above the quicksand layer according to the usual manual hole-digging pile construction method, and pour a section of retaining wall on the inner wall of the pile hole every time a certain depth is excavated. After pouring the retaining wall, the inner diameter of the pile hole is larger than the designed p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com