Manufacturing method for rinsing exposed aggregate colorful concrete external-hung wallboard

A technology of colored concrete and production methods, applied in covering/lining, construction, building construction, etc., can solve the problems of profound and complicated process technology, huge and complicated construction equipment, and radioactive pollution of chemical elements, and achieve low technical requirements and abundant Good architectural appearance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

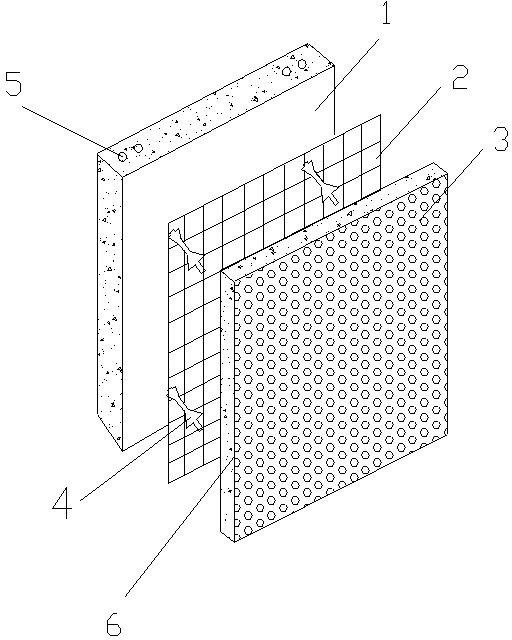

[0023] The invention provides a method for manufacturing an external wall board of colored concrete with washed and exposed aggregate. The outer layer of the external wall board is colored concrete with washed and exposed aggregate.

[0024] The strength grade of the colored concrete is C30, and its mix ratio is: cement P.O42.5 grade 315-335kg / m 3 , fly ash 60-80 kg / m 3 , water 160-170kg / m 3 , fine sand 470-510 kg / m 3 , colored pebble particle size 5~10mm1300-1360 kg / m 3 , naphthalene-based admixture 3.0-3.6 kg / m 3 , The color concrete slump is 70~90mm.

[0025] The concrete water-washing exposed aggregate agent is a chemical preparation, which is used for the treatment of the exposed aggregate on the concrete surface and the decorative treatment of the exposed aggregate on the surface of the concrete member. The chemical preparation is a composite retarder, mainly composed of naphthalene-based water reducer, sugar, potassium sodium tartrate, sodium tripolyphosphate, hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com