Waste gas afterheat boiler for ore heat furnace

A technology of waste heat boiler and submerged arc furnace, which is applied to furnaces, furnace components, waste heat treatment, etc., and can solve problems such as insignificant economic benefits, low energy utilization rate, and unstable safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

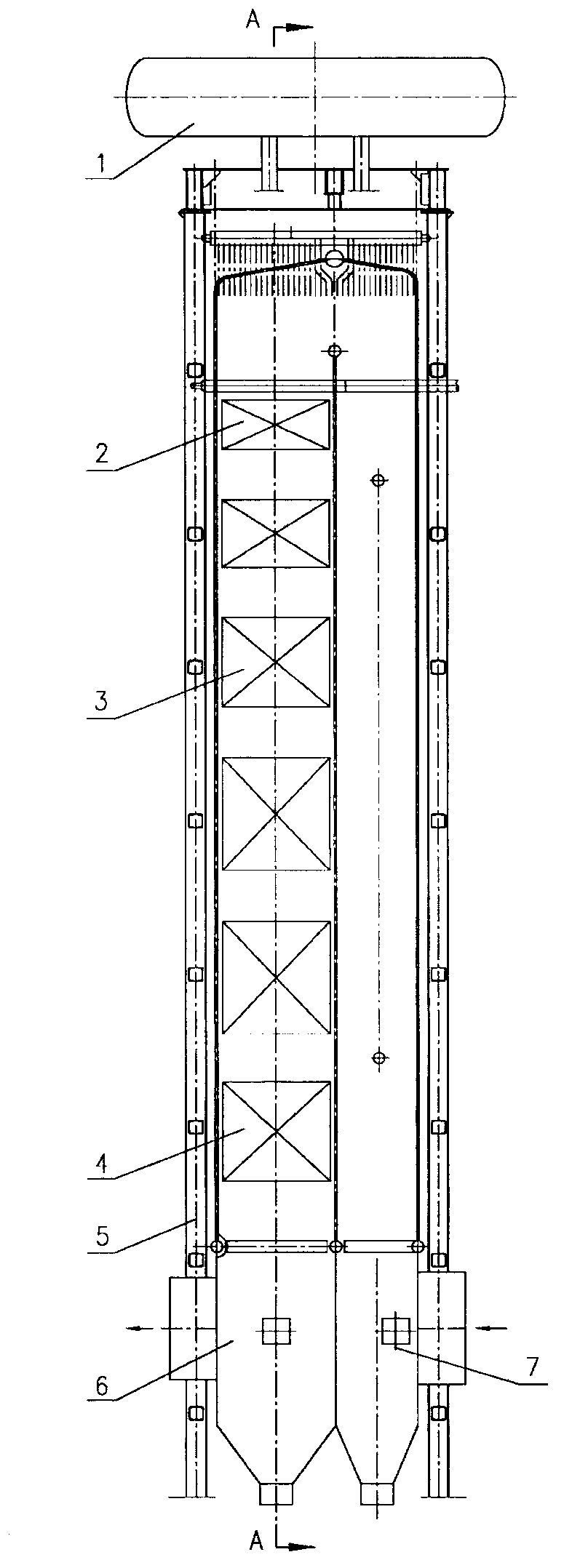

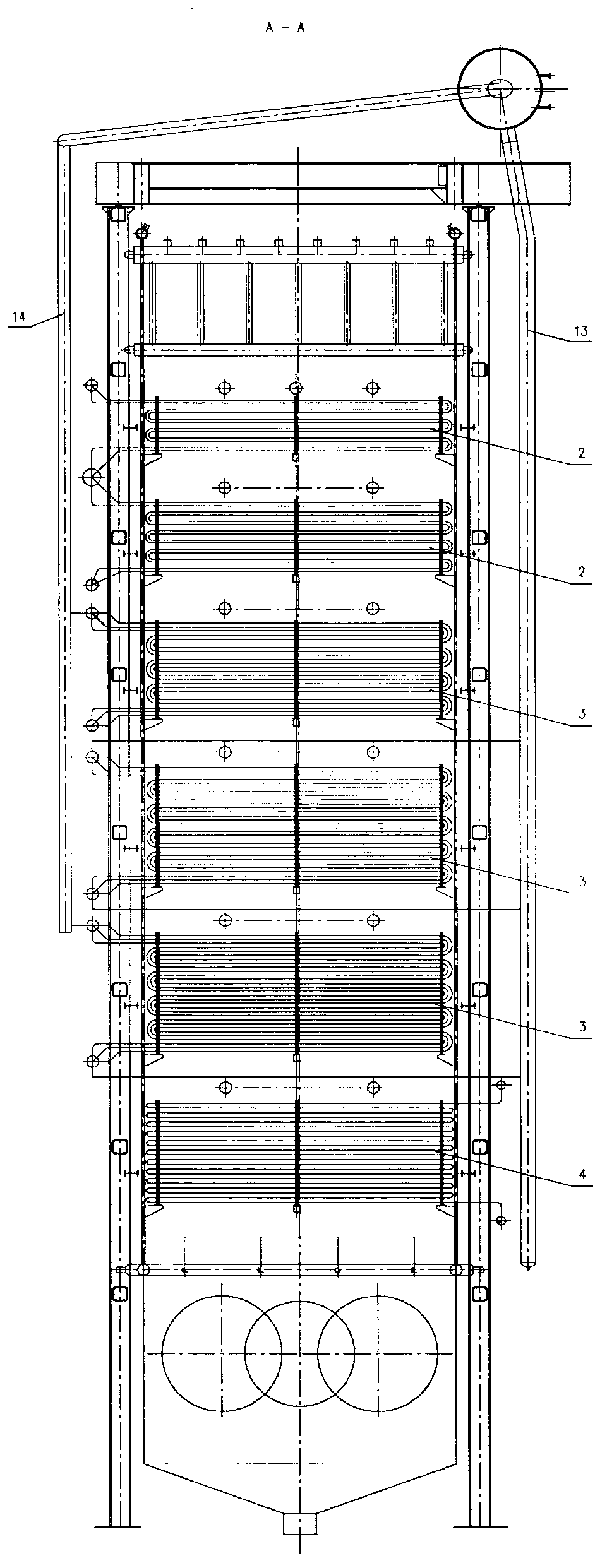

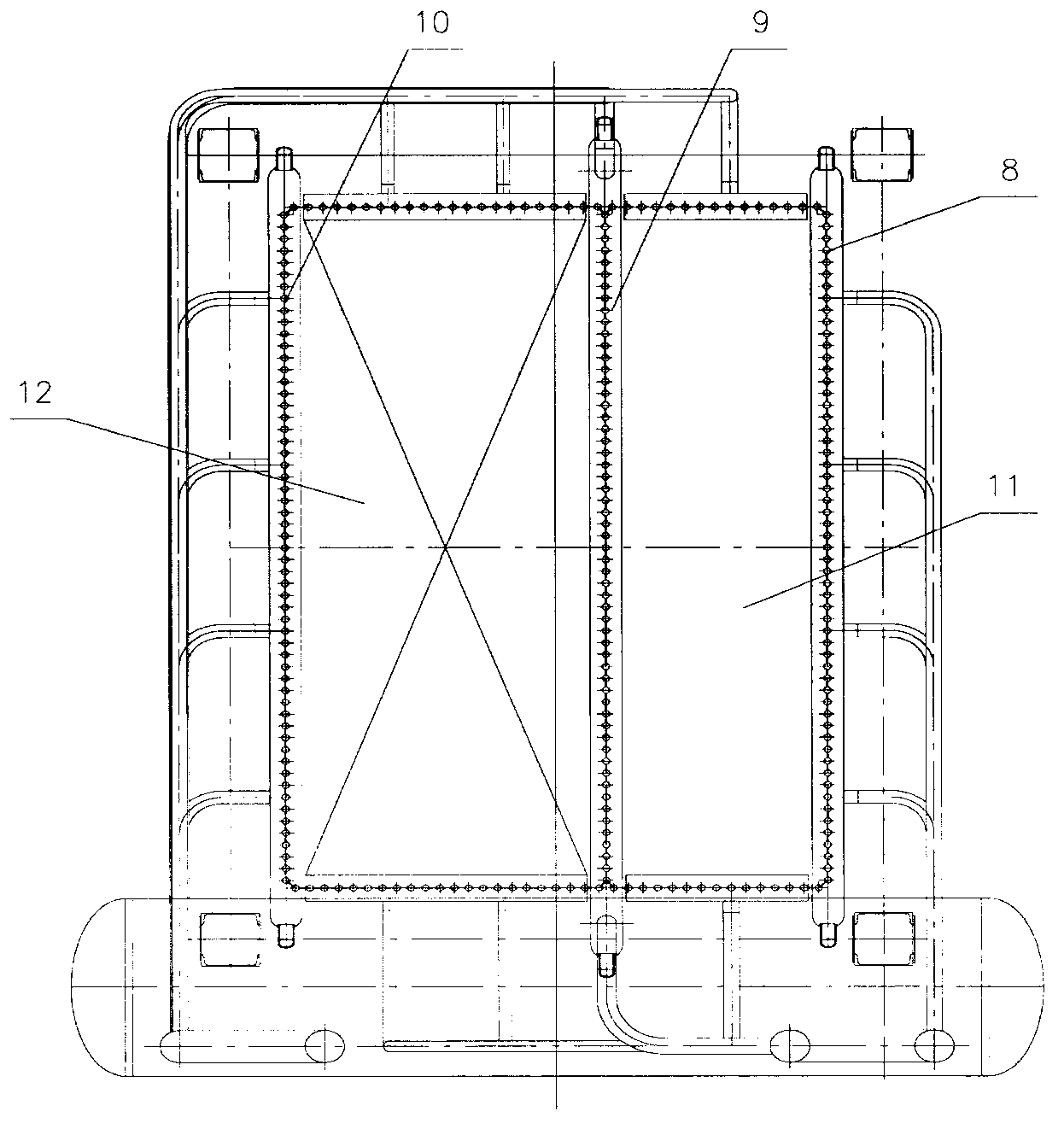

[0014] A submerged arc furnace exhaust gas waste heat boiler, including a drum 1, a superheater 2, an evaporator 3, a water heater 4, a steel frame 5, a flue gas inlet device 6, a flue gas outlet device 7, etc., and is characterized in that it also includes a front chamber Water-cooled wall 8, middle water-cooled partition wall 9, back room water-cooled wall 10, front room water-cooled wall 8 and middle water-cooled wall 9 form cavity front room 11, middle water-cooled wall 9 and rear room water-cooled wall 10 12 in the rear chamber of the tube bundle area.

[0015] The front chamber 11 of the cavity and the rear chamber 12 of the tube bundle area constitute the fully water-cooled double-chamber structure of the exhaust gas waste heat boiler, which is covered by an inverted "U" shape, without horizontal flue.

[0016] The flue gas flow is that the high-temperature flue gas enters the high-temperature-resistant and anti-dusting inlet device, then enters the front chamber of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com