Fixed grate incinerator

A fixed grate and incinerator technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of high-temperature oxidation and burnout of the grate, reduce the fuel consumption of the secondary combustion chamber, etc., and achieve uniform and more oxygen supplementation Full, fuel-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

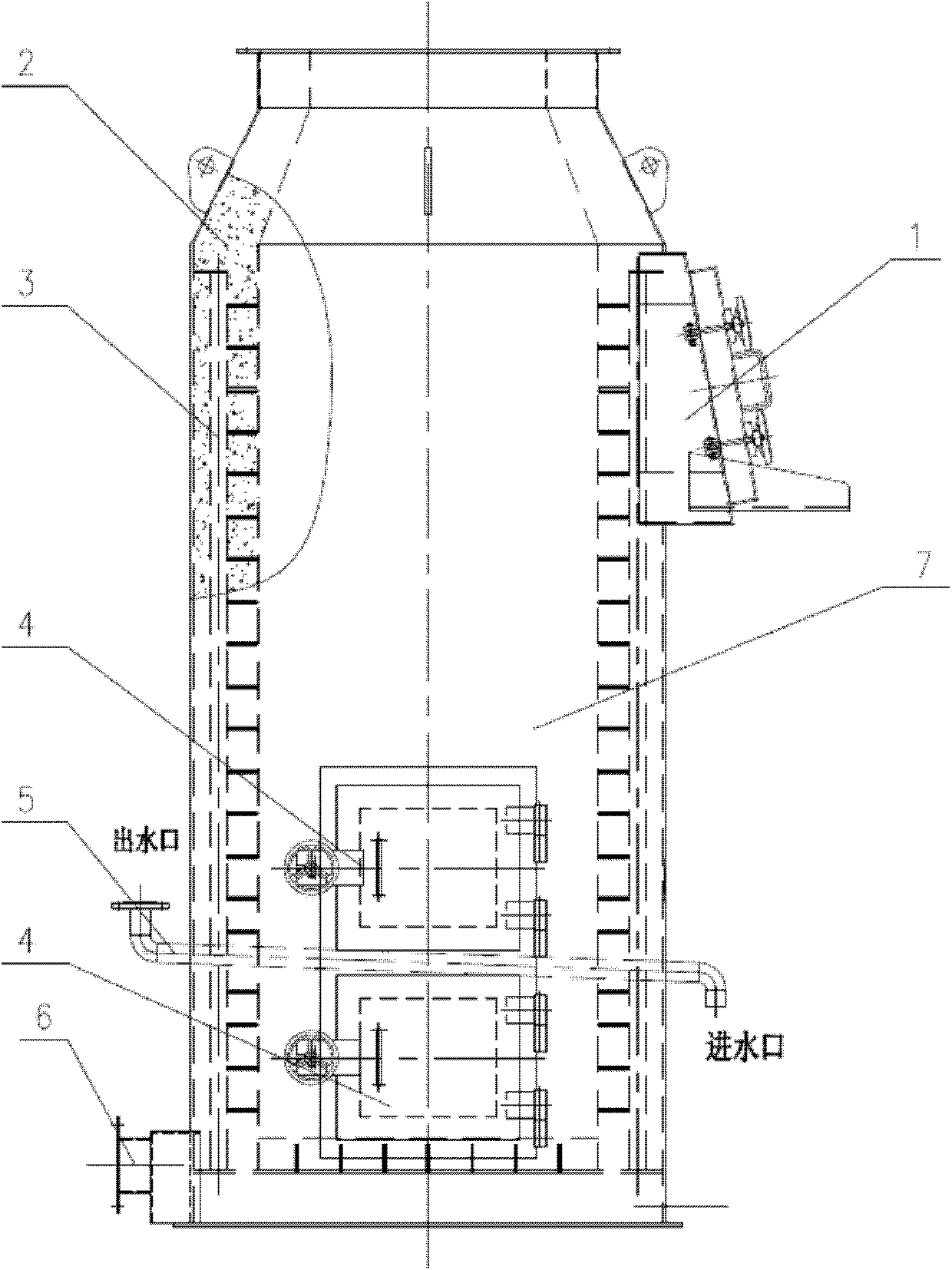

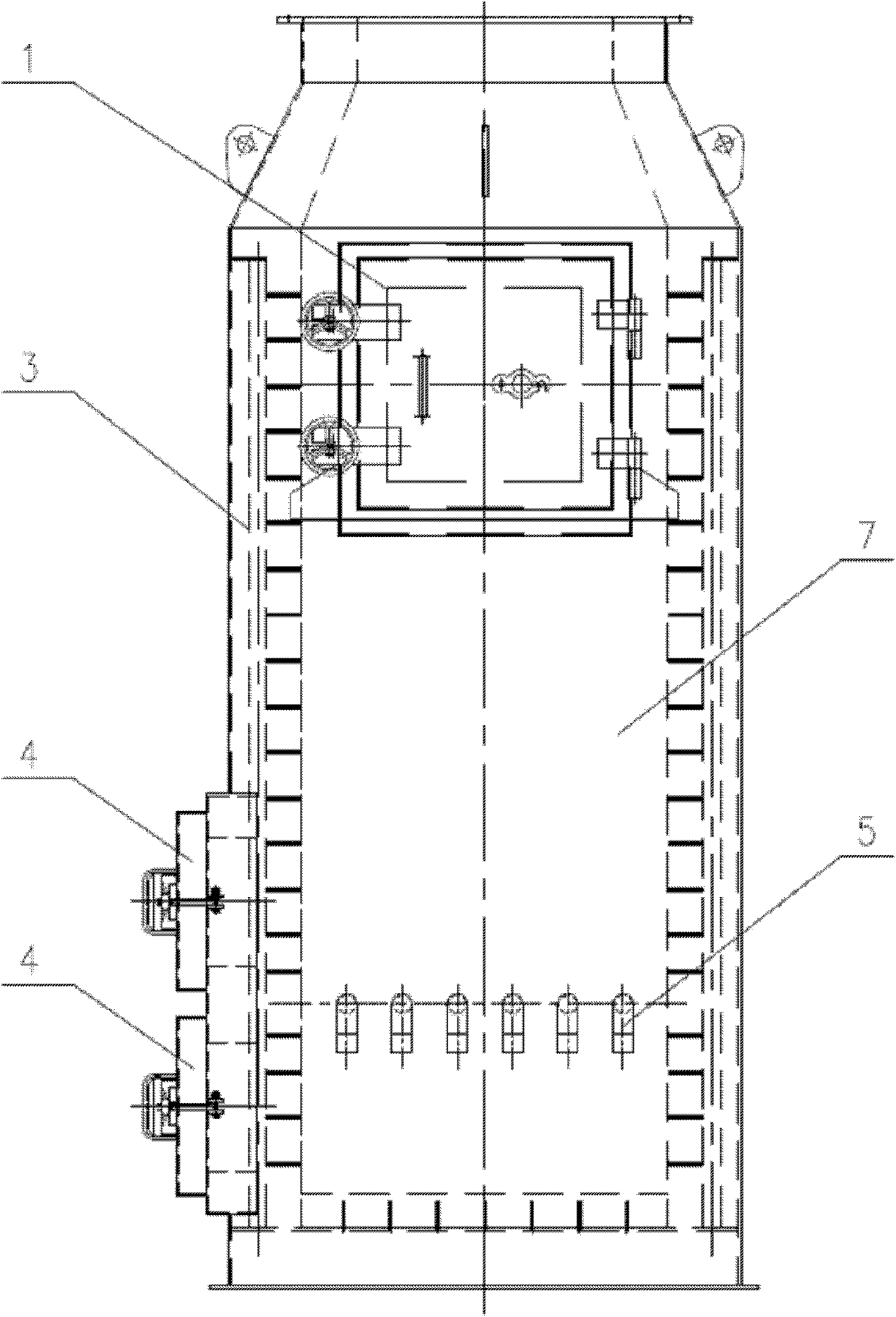

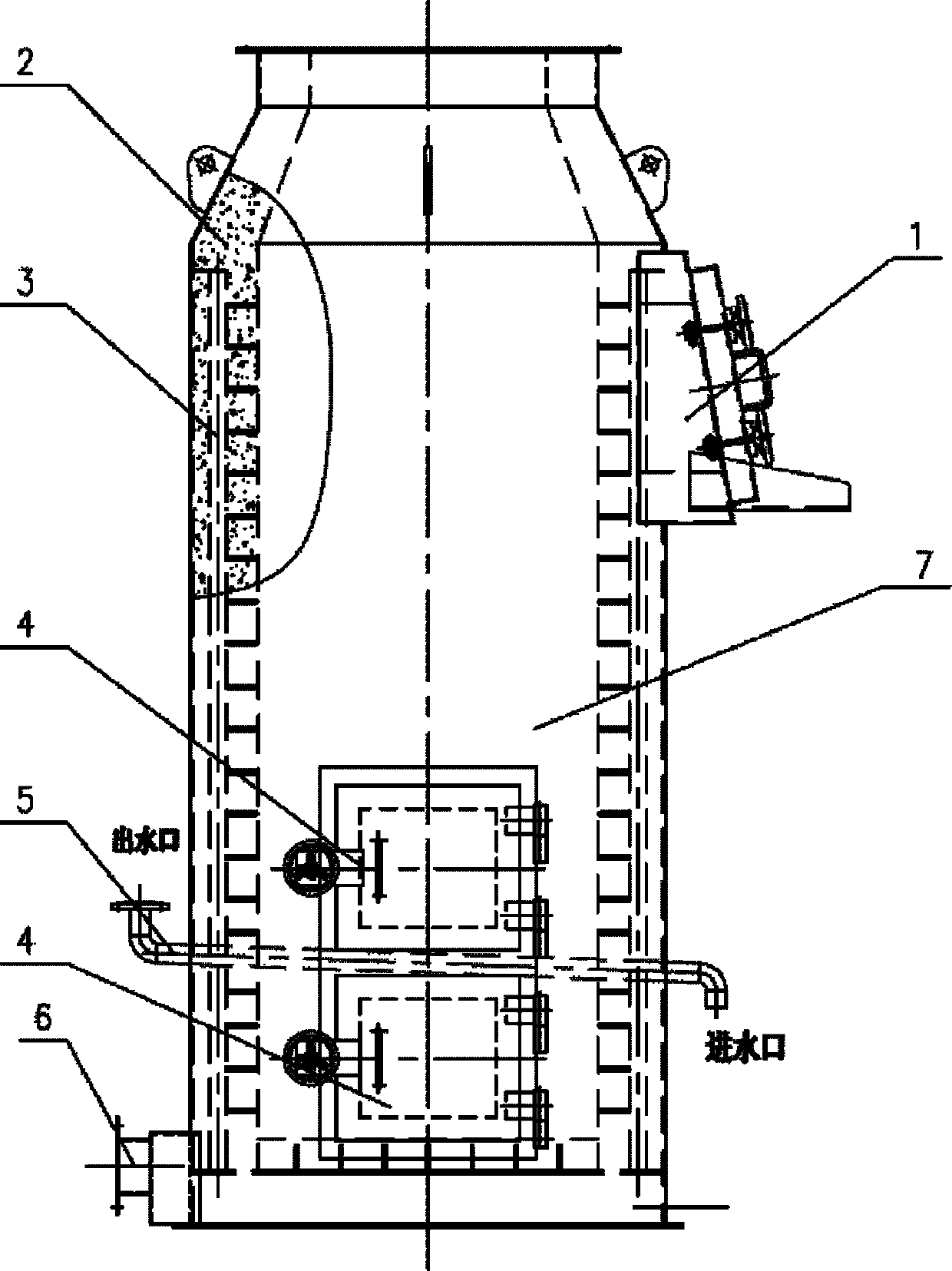

[0019] Fixed grate incinerator, the structure diagram is shown in figure 1 with figure 2 ; Comprising a furnace body 7 made of refractory materials and a water-cooled fire grate 5, the water-cooled fire grate 5 traverses the middle and lower part of the furnace body 7, its water outlet is higher than the water inlet, and the angle between the fire grate plane and the horizontal plane is 3 °. The fire grate has a certain inclination, which is conducive to the discharge of water vapor in the water-cooled fire grate 5, and prevents the fire grate from bursting due to the increase of local pressure due to the inability to discharge air bubbles in time.

[0020] The diameter of the water-cooled grate tube is 50mm, and the distance between the outer walls of adjacent grate tubes is 80mm.

[0021] The furnace body wall 2 and the furnace bottom are uniformly and densely arranged with high-pressure air supply pipes 3, through which high-pressure air is introduced, and the flow rate ...

Embodiment 2

[0024] Fixed grate incinerator, the structure diagram is shown in figure 1 with figure 2 ; Comprising a furnace body 7 made of refractory material and a water-cooled fire grate 5, the water-cooled fire grate 5 traverses the middle and lower part of the furnace body, its water outlet is higher than the water inlet, and the angle between the fire grate plane and the horizontal plane is 5° . The fire grate has a certain inclination, which is conducive to the discharge of water vapor in the water-cooled fire grate 5, and prevents the fire grate from bursting due to the increase of local pressure due to the inability to discharge air bubbles in time.

[0025] The diameter of the water-cooled grate tube is 89mm, and the distance between the outer walls of adjacent grate tubes is 100mm.

[0026] The furnace body wall 2 and the furnace bottom are uniformly and densely arranged with high-pressure air supply pipes 3, through which high-pressure air is introduced, and the flow rate of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com