Device and method for detecting corrosion of metal structure under protective layer through microwave resonance cavity

A microwave resonant cavity and metal structure technology, applied in measurement devices, material analysis using microwave means, instruments, etc., can solve problems such as low resolution, lossy, and easily damaged coating structure, and achieve high resolution and safety. high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

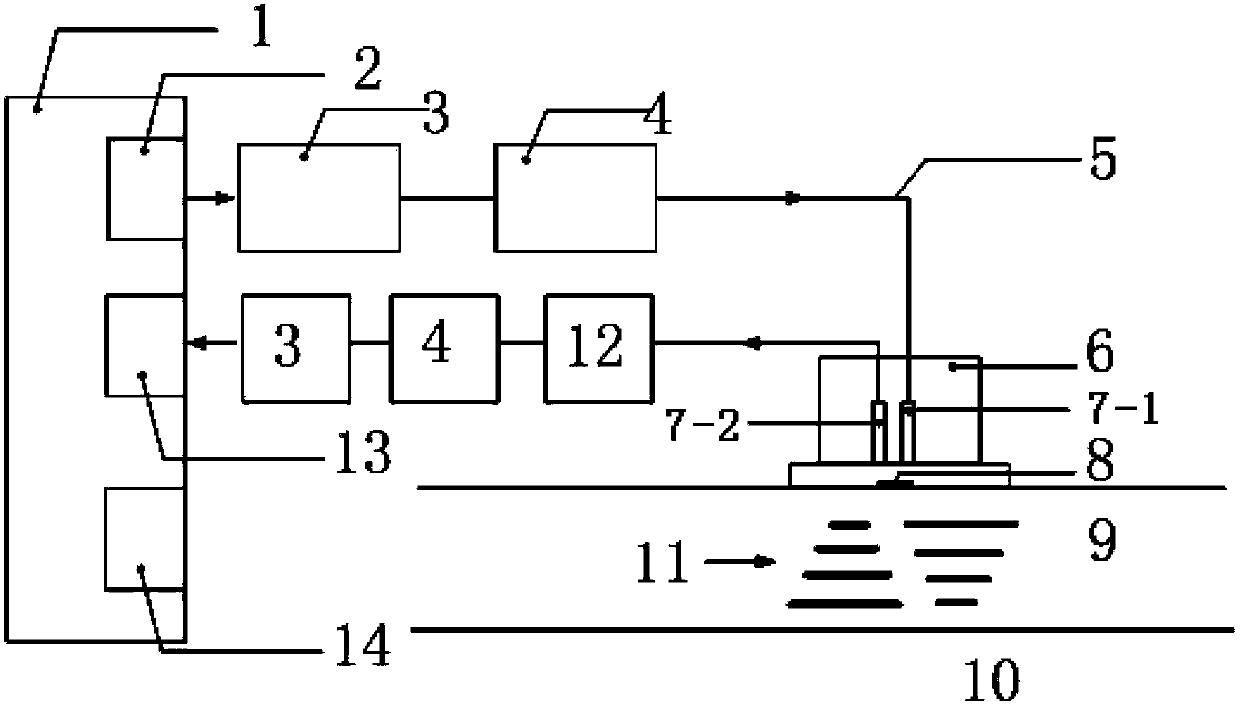

[0024] As shown in the accompanying drawings, a device for microwave resonator detection of metal structure corrosion under the protective layer of the present invention includes an automatic network analyzer 1, a frequency scanning source 2 connected to the automatic network analyzer 1, and the frequency scanning source 2 in turn The connected isolator 3 and adjuster 4, the adjuster 4 is connected with the first coupling probe 7-1 placed in the resonant cavity 6 through the coaxial cable 5, and the second coupling probe 7-1 placed in the resonant cavity 6 The probe 7-2 is connected with the attenuator 12, the adjuster 4, the isolator 3, the signal microprocessor circuit 13) and the automatic network analyzer 1 successively through the coaxial cable 5, and a plurality of corrosion degree indicator lamps 14 are also connected with the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative permittivity | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com