Omnibearing integrated coordination online monitoring system for hydro-power generating unit

A monitoring system and technology for hydropower units, applied in the directions of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as inability to associate, no associated coordination mechanism, and no coordination mechanism, so as to ensure information security and reliability. The effect of interactive timeliness and high operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make it easier for those skilled in the art to understand and implement the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

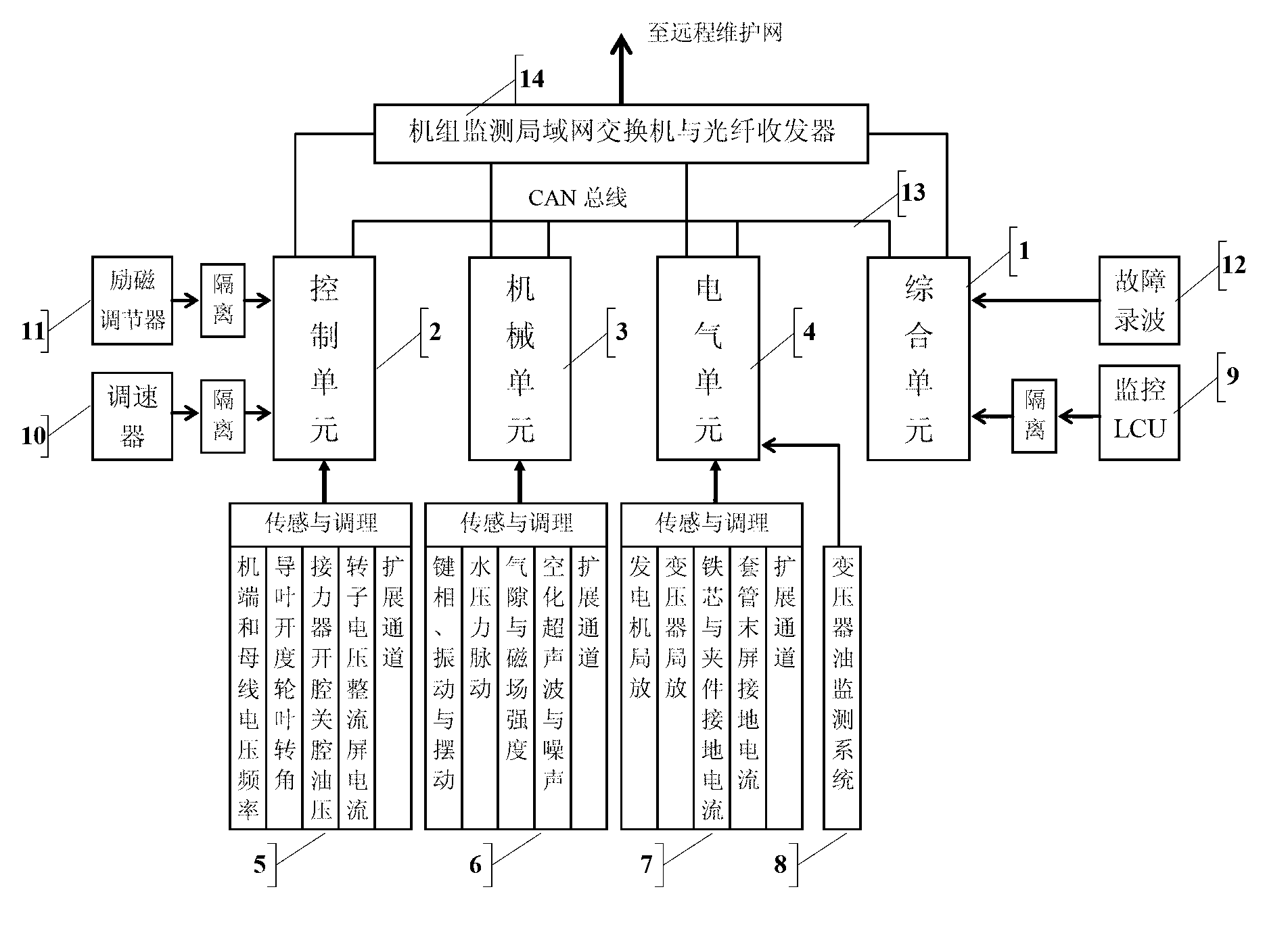

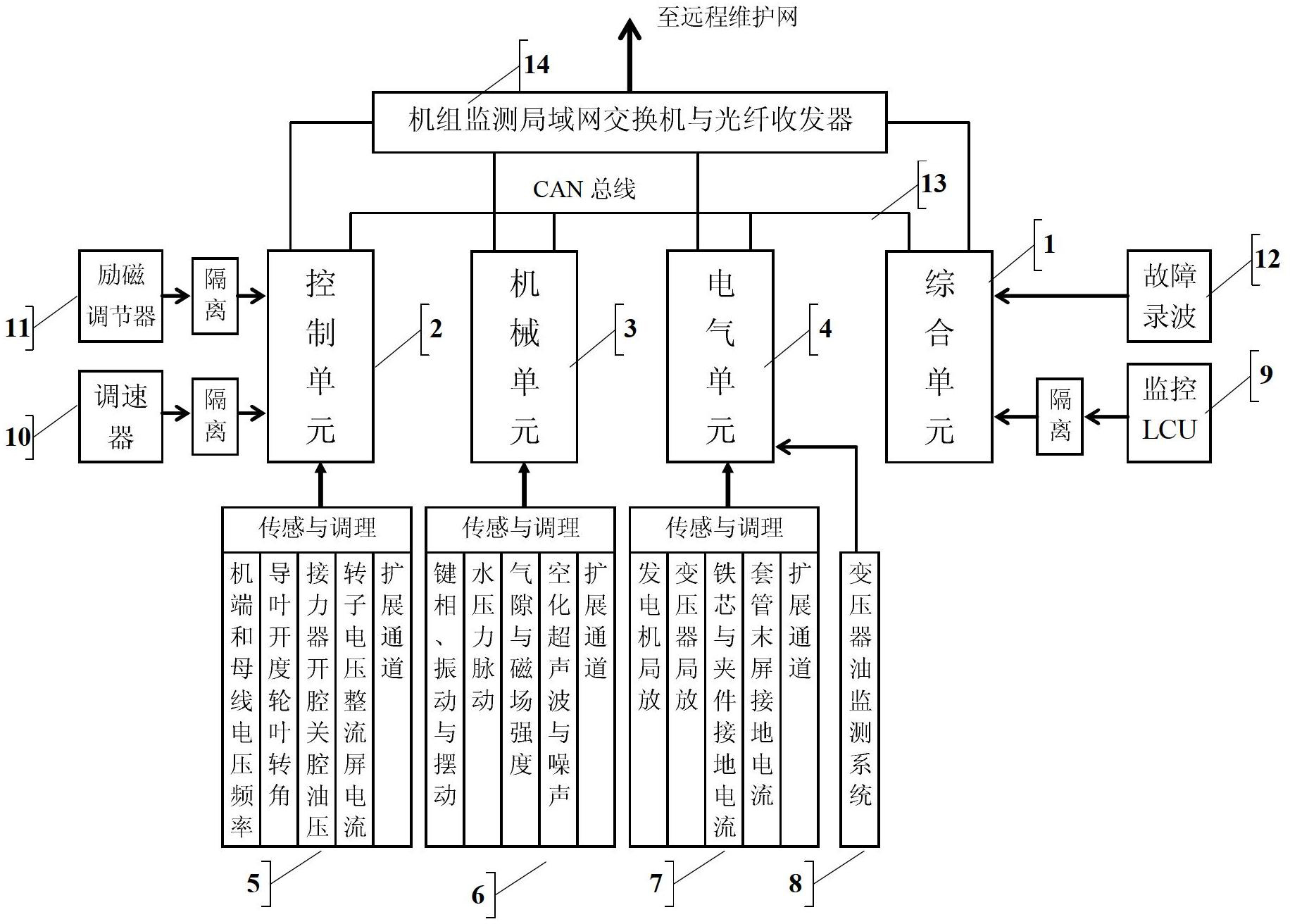

[0036] Such as figure 1As shown, on the basis of fully sharing status information with the existing digital equipment such as LCU8, governor 9 and excitation regulator 10 through the one-way field bus communication with physical isolation, the real-time CAN network 13 and Ethernet 14 will Integrated unit 1, control unit 2, mechanical unit 3, electrical unit 4 and other monitoring units are integrated into a unified platform and constitute an organic unit monitoring team, each monitoring unit is an indispensable member of the monitoring team , not only dedicated to the online monitoring of a certain subsystem or equipment of the unit, but also capable of real-time interaction, information sharing, behavior coordination and associa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com