Temperature control method based on symbol identification in cable current-carrying capacity heat cycling test

A circulating heating and cable technology, which is applied in the direction of temperature control using electric methods, can solve the problems of low control accuracy and long temperature stabilization time, and achieve the effects of clear control logic, temperature overshoot and oscillation suppression, and less calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

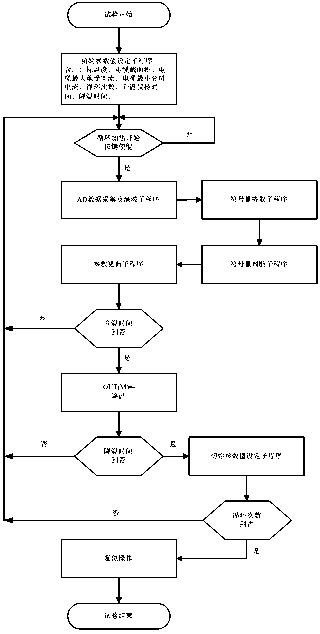

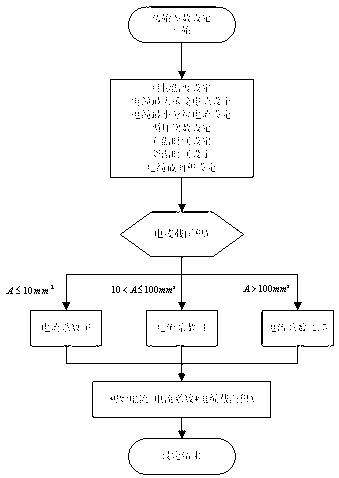

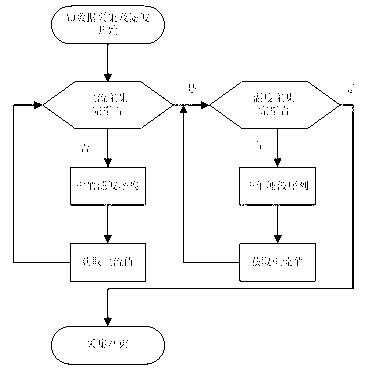

[0050] The present invention is composed of PLC (or single-chip microcomputer) control unit, 12-bit multi-channel AD analog-to-digital conversion unit, I / O input and output unit, sensor and transmission unit, motor and voltage regulator execution unit in terms of hardware; It is composed of initial parameter setting subroutine, AD data acquisition and filtering subroutine, symbolic quantity extraction subroutine, symbolic quantity judgment subroutine, parameter updating subroutine. After the hardware preparation is completed, the temperature sensor and the transmission unit will change the temperature signal from 0 to 200°C (the user can choose a different thermocouple according to the upper limit of the cable test temperature) into a voltage signal of 0 to 5V, and the current sensor and the transmission unit will turn the temperature signal from 0 to 5V. ~2000A current signal (the range can be selected by the user according to the actual load range of the cable) is transformed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com