Sodion battery cathode material

A sodium-ion battery and negative electrode material technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of less sodium-intercalated negative electrode materials and the inability to effectively insert and extract sodium ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1. Polyvinyl chloride pyrolytic carbon and electrochemical sodium storage performance

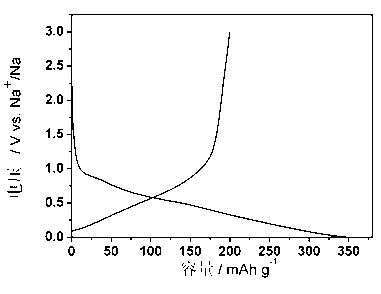

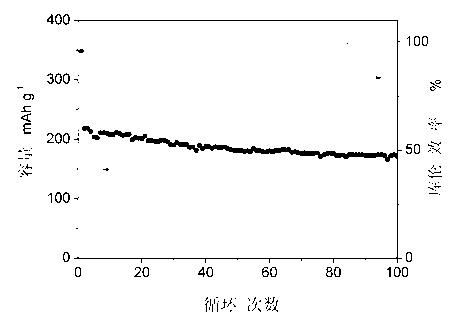

[0022] Place the polyvinyl chloride material in a high-temperature furnace filled with nitrogen, at 600 o C pyrolysis 6h. The obtained carbon material is uniformly mixed with vinylidene fluoride (PVDF) (dissolved in N-methylpyrrolidone) and acetylene black at a weight ratio of 90:5:5, and coated to form an electrode film. With the electrode film as the working electrode and the metal sodium sheet as the counter electrode, 1mol L -1 NaPF 6 (EC-DEC=1:1) Assembled the battery with the electrolyte to test its electrochemical performance, figure 1 The galvanostatic charge-discharge curve of polyvinyl chloride pyrolytic carbon. Such as figure 1 shown at 50 mA g -1 Under the current density, the reversible capacity of the material is 200mAh g -1 . After 100 cycles of battery cycling, 90% of the capacity is still maintained. ( figure 2 )

Embodiment 2

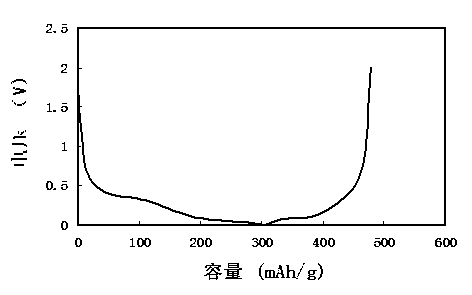

[0023] Example 2. Preparation and sodium storage performance of polythiophene pyrolytic carbon material

[0024] Place the polythiophene material in a high-temperature furnace filled with nitrogen, at 1200 o C pyrolysis for 10 hours, the obtained carbon material is mixed with vinylidene fluoride (PVDF) (dissolved in N-methylpyrrolidone) and acetylene black in a weight ratio of 90:5:5, and coated into an electrode film. With the electrode film as the working electrode and the metal sodium sheet as the counter electrode, 1mol L -1 NaPF 6 (EC-DEC=1:1) Assembled the battery with the electrolyte to test its electrochemical performance, image 3 It is the galvanostatic cycle performance curve of phenolic resin pyrolytic carbon, the current density is 50 mA g -1 , the charging and discharging voltage range is 2.0~0V (Na + / Na). Such as image 3 The material shown has a reversible capacity of 170mAh g -1 . Figure 4 is the cycle curve of the material. The capacity still main...

Embodiment 3

[0026] Embodiment 3. Preparation and sodium storage performance of polyaniline pyrolytic carbon

[0027] Place the polyaniline material in a high-temperature furnace filled with nitrogen, at 1000 o C pyrolysis for 6 hours, the obtained carbon material is mixed with vinylidene fluoride (PVDF) (dissolved in N-methylpyrrolidone) and acetylene black in a weight ratio of 90:5:5, and coated into an electrode film. With the electrode film as the working electrode and the metal sodium sheet as the counter electrode, 1mol L -1 NaPF 6 (EC-DEC=1:1) Assembled the battery with the electrolyte to test its electrochemical performance, the current density was 50 mA g -1 , the charging and discharging voltage range is 1.2~0V (Na + / Na). The tested material has a reversible capacity of 250 mAh g -1 , the capacity still maintains 220 mAh g after 100 cycles -1 .

[0028]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reversible capacity | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com