Protocol conversion device based on DeviceNet-Modbus

A protocol conversion and communication device technology, applied in the field of industrial automatic control and data communication, can solve the problem of not having DeviceNet slave communication, and achieve the effect of enhancing portability and facilitating debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

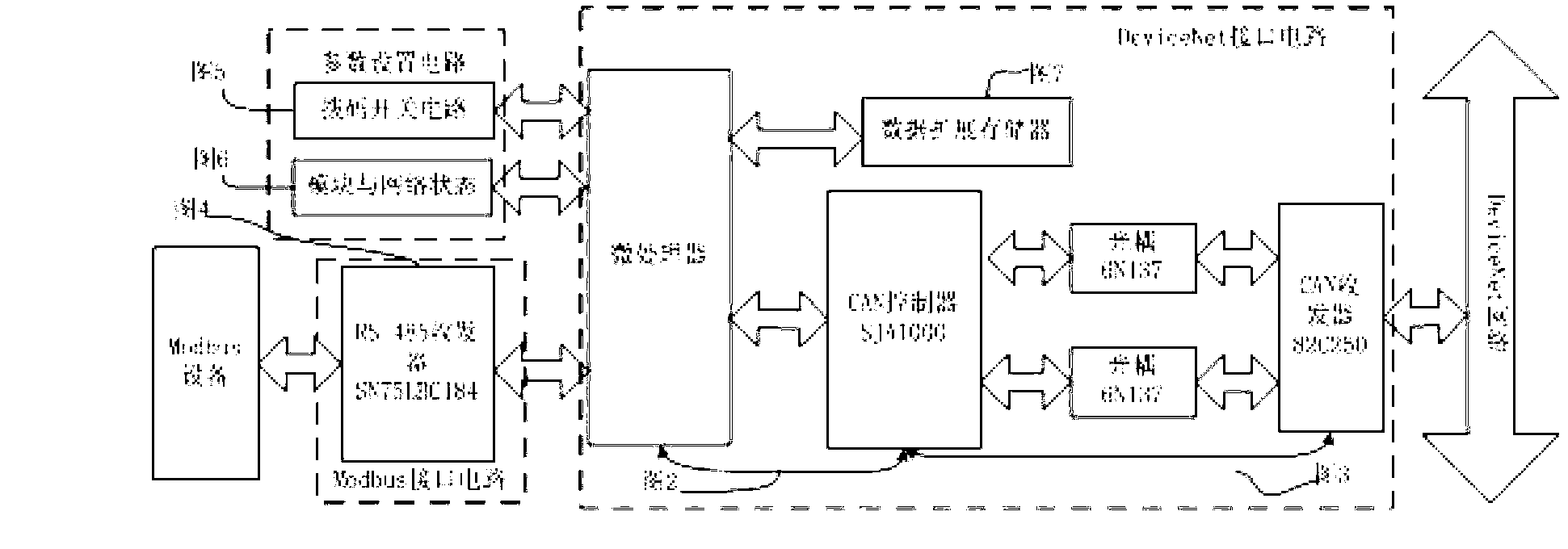

[0034] Such as figure 1 The general structure diagram of the protocol conversion device based on DeviceNet-Modbus is shown, which includes:

[0035] DeviceNet interface circuit: for receiving and sending and analyzing and processing the data information of DeviceNet master station and protocol conversion module;

[0036] Modbus interface circuit: used to receive the Modbus command sent by the protocol conversion module, and send the Modbus device response message to the protocol conversion module;

[0037] Parameter setting circuit: used to set the communication baud rate and bus node number of the communication device, and reflect the working status and communication status of the communication device in real time;

[0038] The DeviceNet interface circuit part described therein includes:

[0039] Microprocessor: used to send Modbus commands to the Modbus interface circuit and respond to Modbus commands to the DeviceNet interface circuit, receive the data provided by the DIP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com