Method for producing a hydraulic composition having entrained air

一种水硬性、组合物的技术,应用在制备生产线,混凝土(其中至少一个组分含有碳质材料领域,能够解决降低吸气剂效率等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

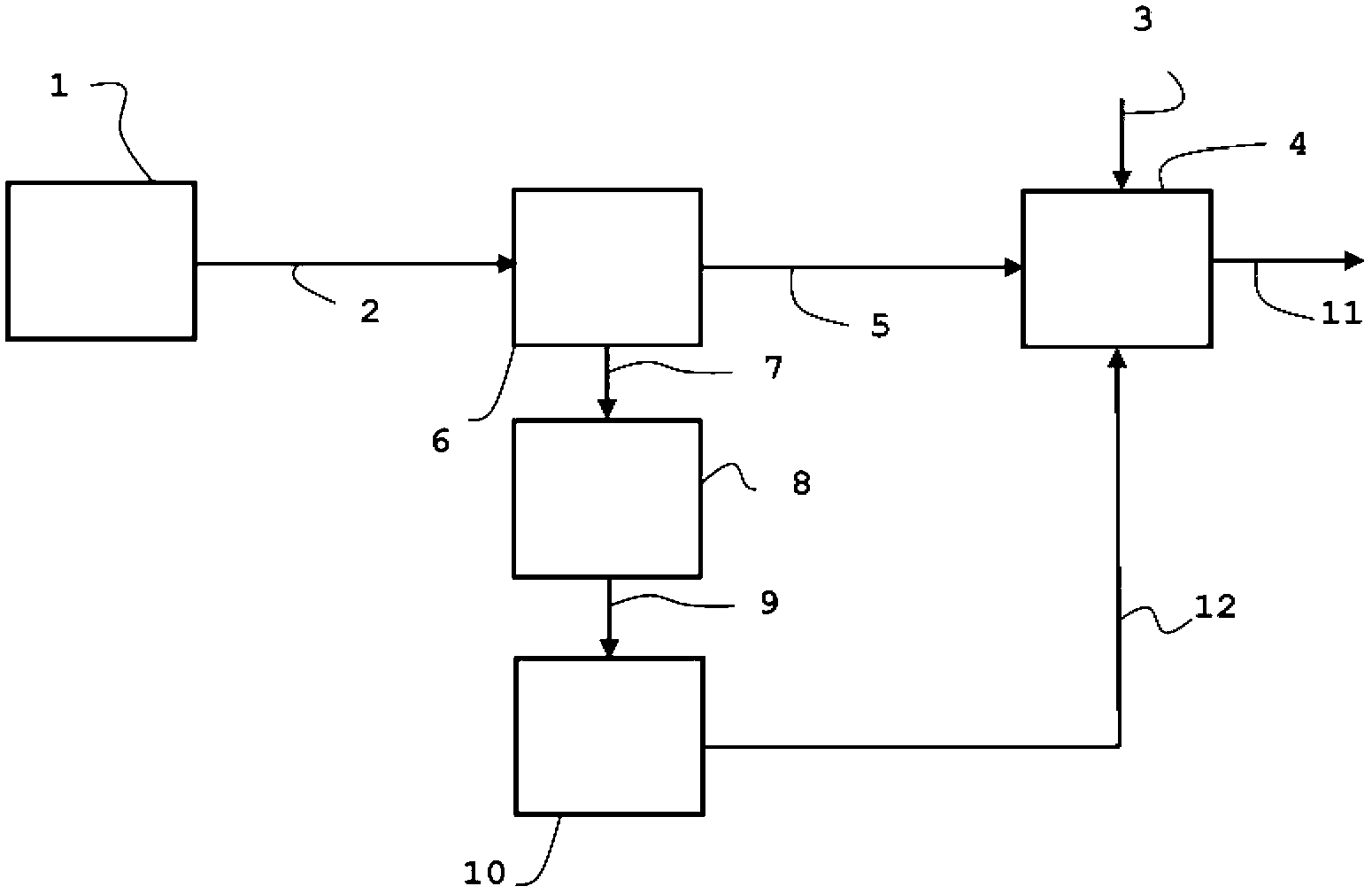

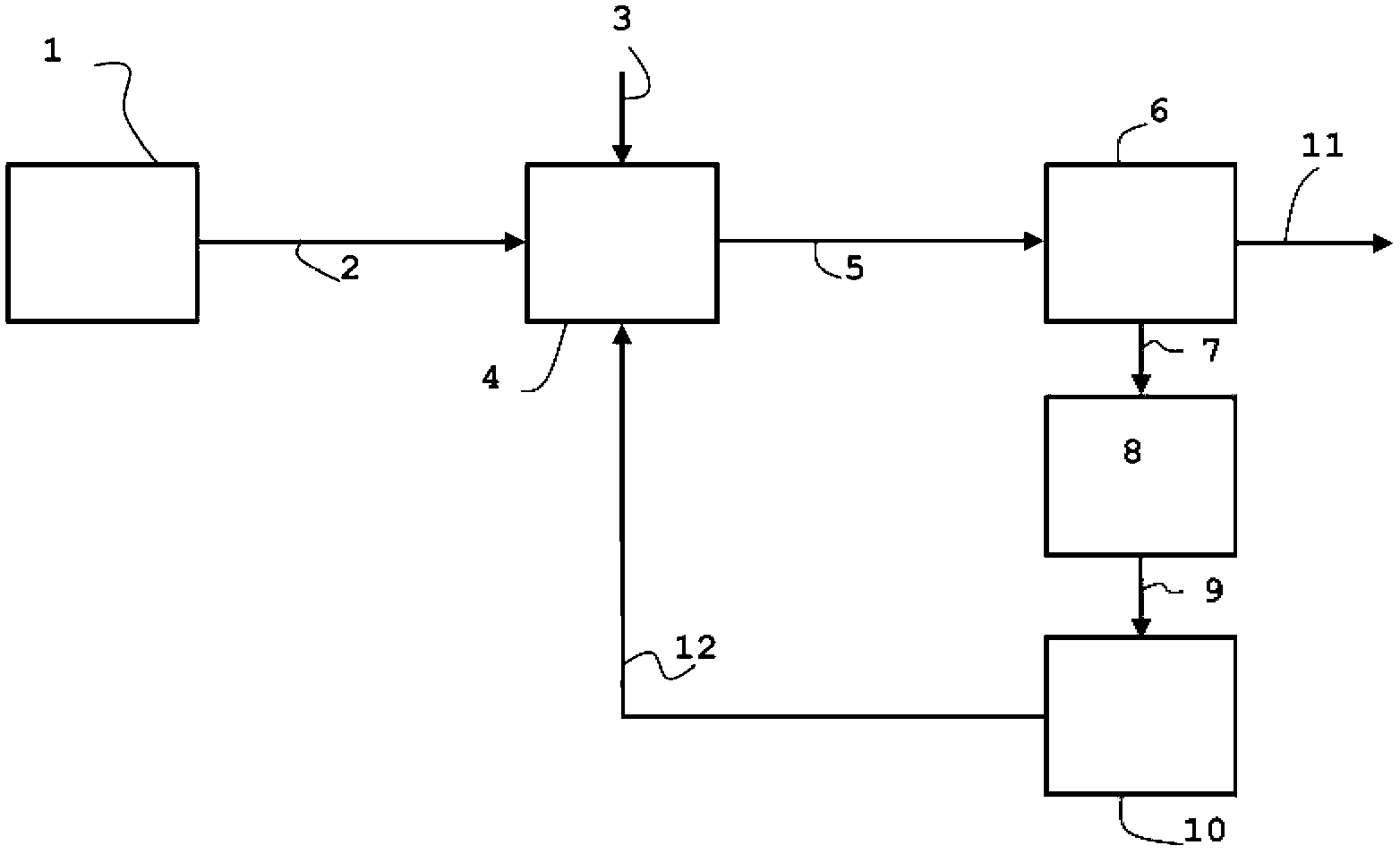

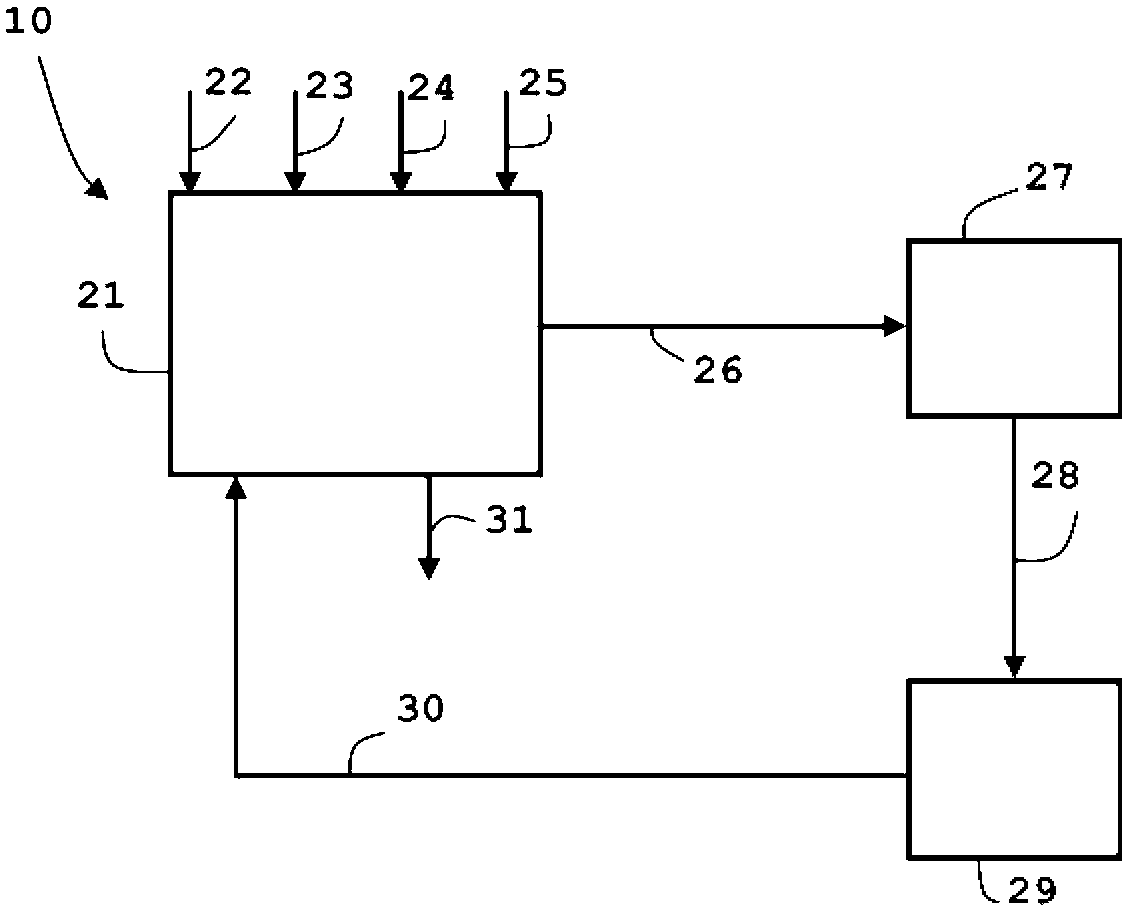

[0155] In the method for producing a composition containing fly ash according to the present invention, for example, fly ash is supplied alone through the supply device 1 and conveyed through the conveying device 2 . A given fly ash consists of a powder having an average particle size between 0.1 and 200 microns and preferably below 45 microns.

[0156] At a certain point in the processing line (before and / or after the inerting process), samples of fly ash are taken automatically on a regular or sporadic basis.

[0157] The term "periodic sampling" should be understood as repeated sampling of successive fly ash samples. It may be drawn at regular intervals, such as weekly or daily or hourly, or even every ten minutes or even more frequently. The duration of extraction may also vary from seconds to minutes. It can also be drawn at irregular intervals. For example, if the fly ash has relatively uniform and constant characteristics, the frequency of extraction can be reduced, ...

Embodiment 1

[0228] Example 1 - Formulate the amount of getter to be added to the hydraulic composition to be tested a measurement method

[0229] A first example of the above-described method for preparing a hydraulically setting composition according to the invention was carried out. Fly ash contaminated with activated carbon was simulated using fly ash without activated carbon, to which activated carbon was added. This enables simple variation of the amount of activated carbon associated with the fly ash.

[0230] The reference fly ash was Wilshire fly ash which contained essentially no activated carbon. The reference activated carbon is GLZ50. The reference hydraulic composition corresponds to a mortar according to formulation (1), wherein the fly ash is Wilshire fly ash. The hydraulic binder corresponds to a monolith comprising Portland cement and fly ash. The optimal concentration of getter was considered to be the concentration that resulted in 10% air content. The tests we...

Embodiment 2

[0250] Example 2 - Determination of the amount of inert agent from the methylene blue value of mortar with fly ash

[0251] A third example of the above-described method for preparing a hydraulically setting composition according to the invention was carried out. In this example, the inert used was Pluronic® by BASF under the trade name Pluronic TM Inert agent sold under RPE 1720. Pluronic TM RPE 1720 inert is a PO / EO / PO type triblock polymer (polypropylene oxide / polyethylene oxide / polypropylene oxide) with a molecular weight of 2150 g / mol containing 20% ethylene oxide content. The reference fly ash is Wilshire fly ash. The reference activated carbon is GLZ50. The reference hydraulic composition corresponds to the mortar according to formulation (1) and contains 100 ppm of getter. The optimal concentration of the inert agent was considered to be that which resulted in a 10% air content. The tests were carried out by varying the amount of activated carbon added to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com