Re-constructable formed milling cutter for fine machining of circular-arc-shaped curved mortise of wheel disc

A technology of arc curve and mortise and groove, which is applied in the field of reconfigurable milling cutters and cutting tools, can solve the problems of uneven wear and high cost, and achieve the effect of solving cost, good reconfigurability and slowing down wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and Examples. The present embodiment provides detailed implementation and specific operation process on the premise of the technical solution of the present invention, but the protection scope of the present invention is not limited to the following Example.

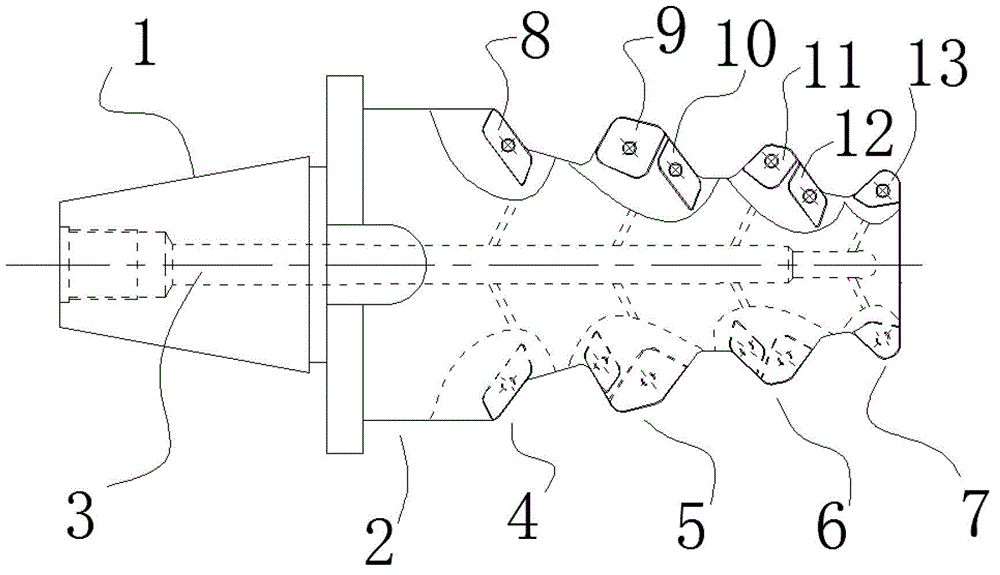

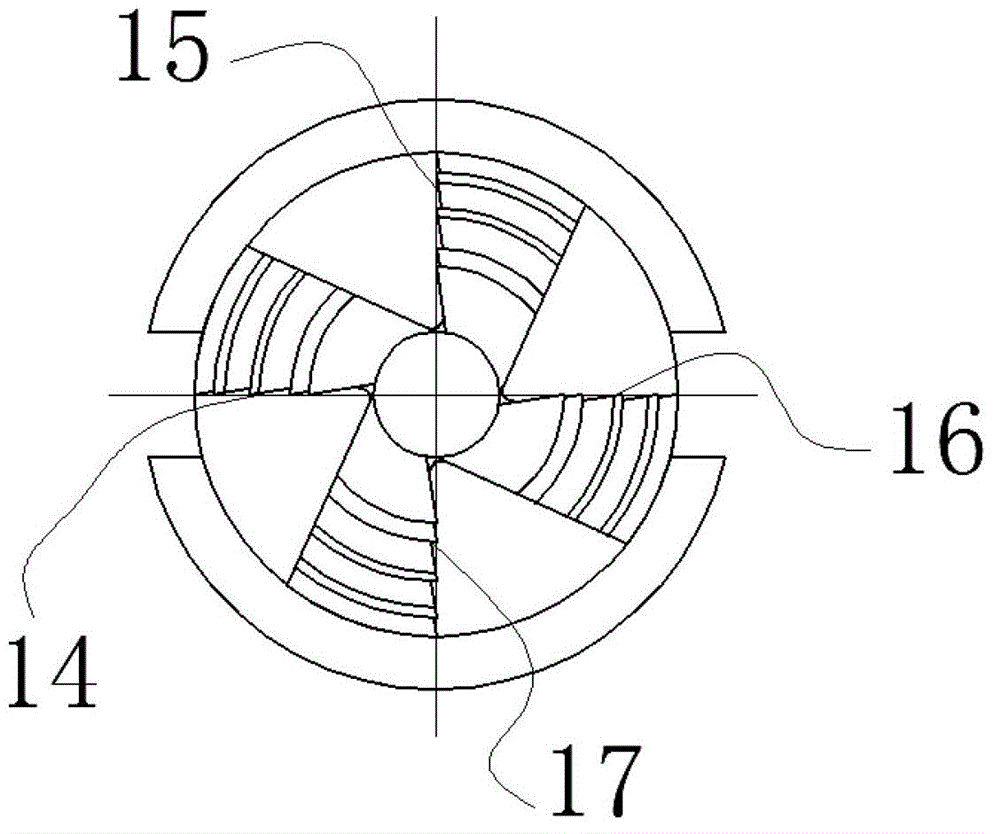

[0015] Such as figure 1 As shown, the reconfigurable shape milling cutter for arc-curve mortise finishing of the present invention includes a shank part 1 and a cutting part 2, wherein the cutting part 2 is fixed on the end of the shank part 1, which is fir-shaped. Tree-shaped, with the top pointing to the tip of the knife; the base material of the cutting part 2 is fine-grained powder metallurgy high-cobalt vanadium-containing high-speed steel with a hardness of HRC65-67. The inside of the forming milling cutter is provided with a tool installation hole and an internal cooling passage 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com