Preparation method of cryolite

A cryolite and polysilicon technology, applied in the field of cryolite preparation, can solve the problems of strong corrosion and toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The core of the present invention is to provide a preparation method of cryolite. On the one hand, this preparation method can make full use of the by-products fluosilicic acid and sodium aluminum tetrafluoride produced in the process of preparing polysilicon by the silane method, and the cost of raw materials is low; on the other hand, it can avoid The corrosive and toxic hydrogen fluoride gas produced by dry and wet preparation of cryolite in the prior art has good safety and environmental protection.

[0032] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

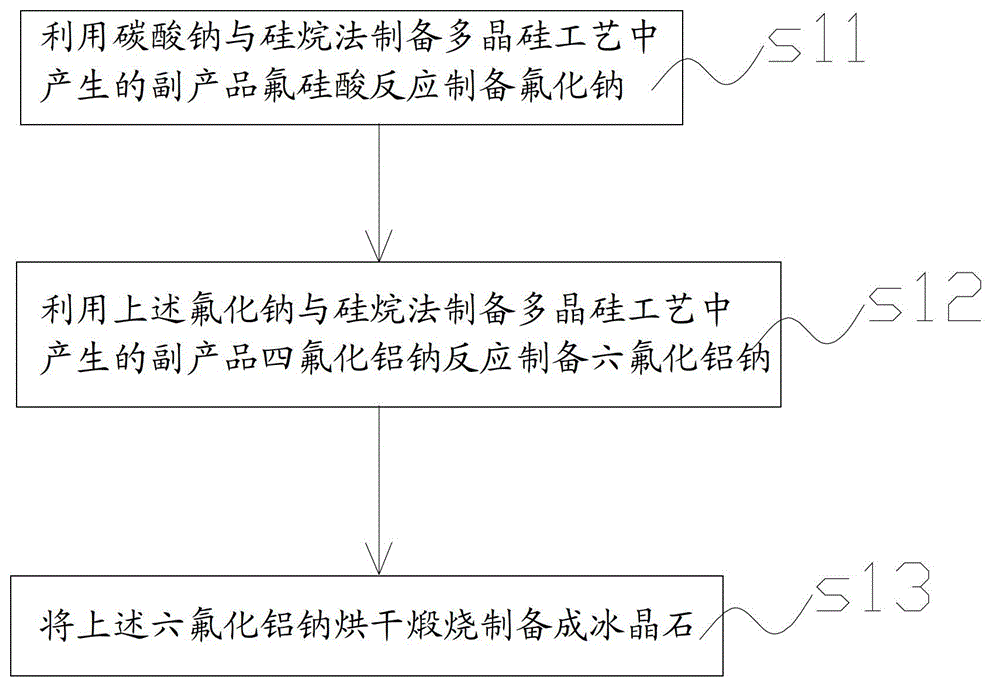

[0033] Please refer to figure 1 , figure 1 It is a flow chart of the preparation method of cryolite in an embodiment of the present invention.

[0034] In one embodiment, the preparation method of cryolite provi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com