Novel preparation method of superhydrophobic glass

A superhydrophobic and glass technology, which is applied in the field of superhydrophobic glass preparation, can solve the problems of limited superhydrophobic glass, and achieve the effects of stable superhydrophobic properties, good industrial application prospects, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

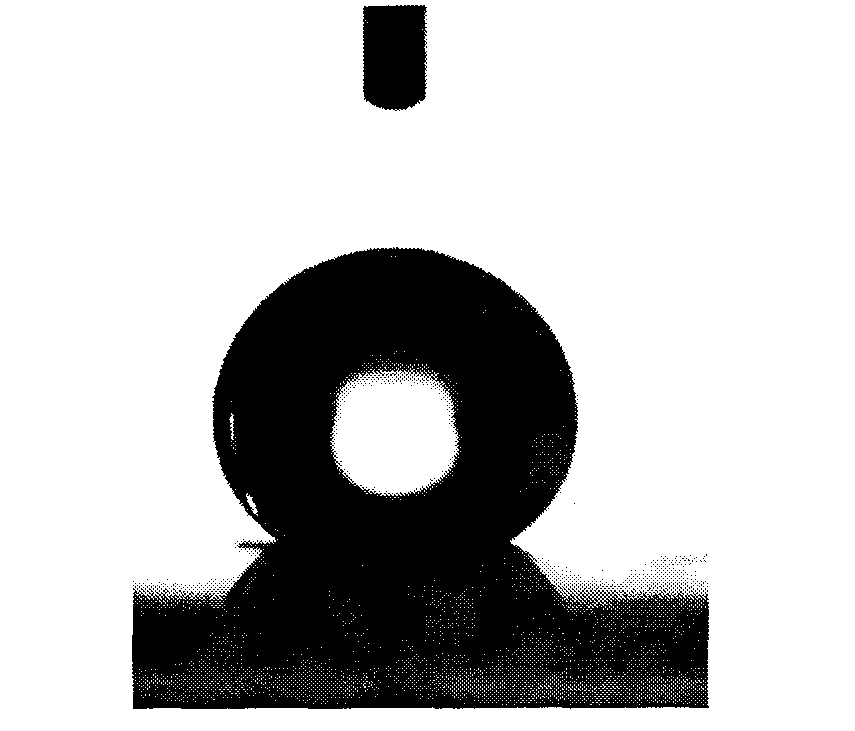

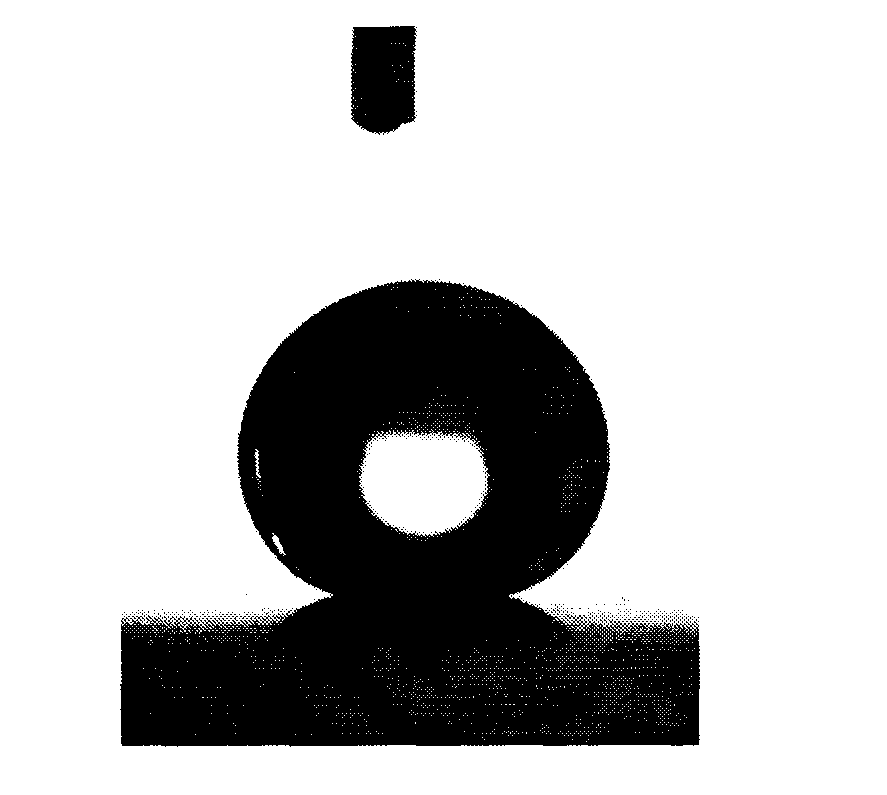

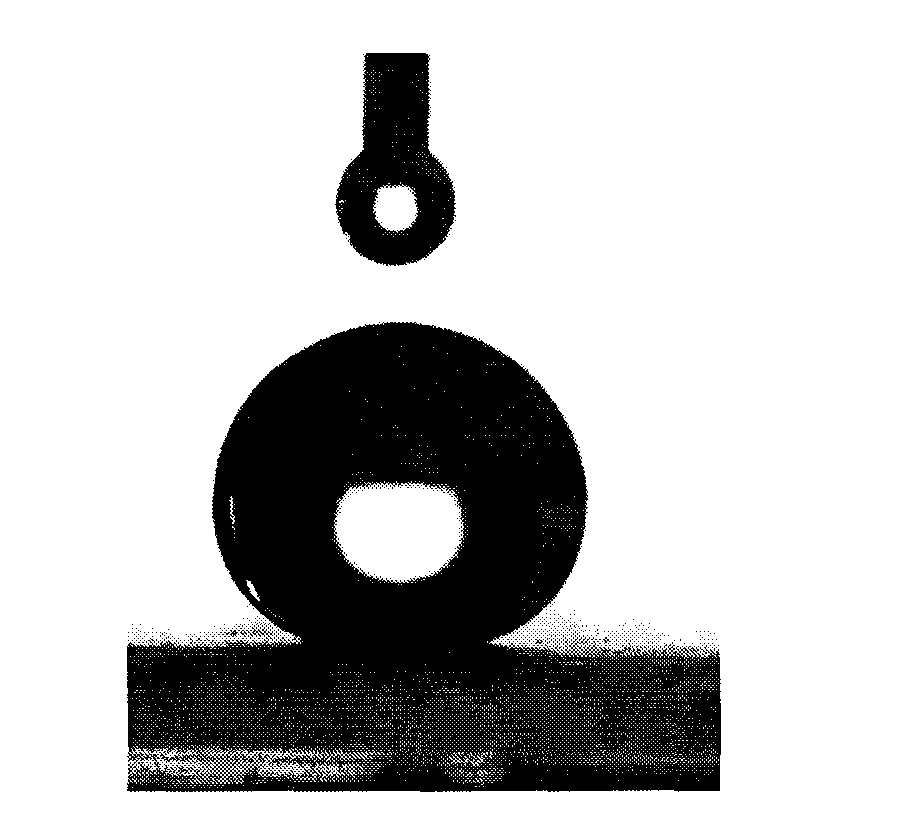

Image

Examples

Embodiment 1

[0029] (1) First, alternately clean the glass surface 3 times with absolute ethanol and acetone, each cleaning time is 5 minutes; then the glass is placed in a mixed solution of 30% hydrogen peroxide and concentrated sulfuric acid (the volume of hydrogen peroxide and concentrated sulfuric acid is 30:70) for 5 minutes, then washed 3 times with deionized water, and then dried in a nitrogen environment for 2 hours;

[0030] (2) Add 10nm, 20nm, 50nm, 80nm, 100nm, 150nm nano silicon dioxide to 1000mL absolute ethanol with a weight ratio of 10:10:20:20:20:20 and stir for 30 minutes to form a concentration of 1wt % nano silicon dioxide solution;

[0031] (3) Immerse the cleaned glass in the nano-silica solution for 20 minutes, then pull it out from the nano-silica solution at a speed of 5 cm / min, and dry it at 400° C. for 5 hours;

[0032] (4) Repeat step (3) 3 times;

[0033] (5) Place the glass impregnated with nano-silica in the ethanol solution of 1wt% heptadecafluorotrimethoxy...

Embodiment 2

[0035] (1) First, alternately clean the glass surface 5 times with absolute ethanol and acetone, and each cleaning time is 10 minutes; then the glass is placed in a mixed solution of 30% hydrogen peroxide and concentrated sulfuric acid (the volume of hydrogen peroxide and concentrated sulfuric acid is 30:70) for 5 minutes, then washed 3 times with deionized water, and then dried in a nitrogen environment for 2 hours;

[0036] (2) Add 10nm, 20nm, 50nm, 80nm, 100nm, 150nm nano-silica to 1000mL absolute ethanol with a weight ratio of 25:15:10:20:20:10 and stir for 30 minutes to form a concentration of 1wt % nano silicon dioxide solution;

[0037] (3) Immerse the cleaned glass in the nano-silica solution for 30 minutes, then pull it out from the nano-silica solution at a speed of 1 cm / min, and dry it at 400° C. for 8 hours;

[0038] (4) Repeat step (3) 3 times;

[0039] (5) Place the glass impregnated with nano-silica in the ethanol solution of 1wt% heptadecafluorotrimethoxyetho...

Embodiment 3

[0041] (1) First, alternately clean the glass surface with absolute ethanol and acetone for 4 times, each cleaning time is 8 minutes; then the glass is placed in a mixed solution of 30% hydrogen peroxide and concentrated sulfuric acid (the volume of hydrogen peroxide and concentrated sulfuric acid is 30:70) for 5 minutes, then washed 3 times with deionized water, and then dried in a nitrogen environment for 2 hours;

[0042] (2) Add 10nm, 20nm, 50nm, 80nm, 100nm, 150nm nano-silica to 1000mL absolute ethanol with a weight ratio of 20:30:10:10:15:15 and stir for 30 minutes to form a concentration of 2wt % nano silicon dioxide solution;

[0043] (3) Immerse the cleaned glass in the nano-silica solution for 20 minutes, then pull it out from the nano-silica solution at a speed of 10 cm / min, and dry it at 400° C. for 10 hours;

[0044] (4) Repeat step (3) 3 times;

[0045] (5) Place the glass impregnated with nano-silica in a stearic acid ethanol solution with a concentration of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com