Flow rotating combined device for micro-arc oxidation

A combined device and micro-arc oxidation technology, applied in the direction of anodic oxidation, can solve the problems of large oxidation area, increased cost, uneven film layer, etc., and achieve the effect of uniform film layer, saving liquid and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

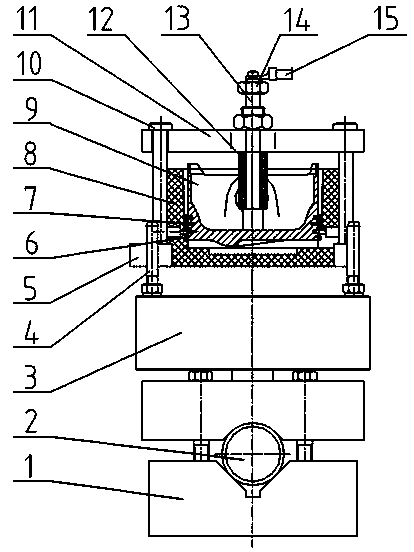

[0017] Below in conjunction with accompanying drawing description, the present invention is described in further detail:

[0018] As shown in the figure, the micro-arc oxidation swirl combination device includes a circulating pump for transporting electrolyte, a storage piston 9 connected with the circulating pump and a sleeve 8 for electrolyte, a micro-arc discharge device, a piston clamping device and a swirl device , the piston clamping device is fixedly connected above the swirl device through a support rod, the liquid spray port of the swirl device is facing the ring groove of the piston 9 tightened on the piston clamping device, and a retaining ring 7 is arranged on the upper side of the ring groove, The lower side is provided with a sealing ring 6 .

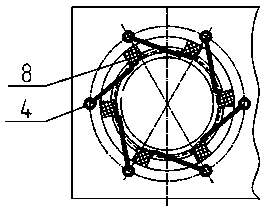

[0019] The swirl device includes a bracket 1, a liquid inlet pipe 2, a nozzle 3, and a liquid spray pipe 4. One end of the liquid spray pipe 4 is connected to the inside of the sleeve 8 and is opposite to the ring groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com