A special-shaped external wall insulation board and its production method

An external wall thermal insulation board and special-shaped technology, which is applied in thermal insulation, chemical instruments and methods, layered products, etc., can solve the problems of insufficient application of complex building components, hollow vacuum insulation boards, and poor mortar adhesion. The effect of good thermal insulation, enhanced adhesion and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

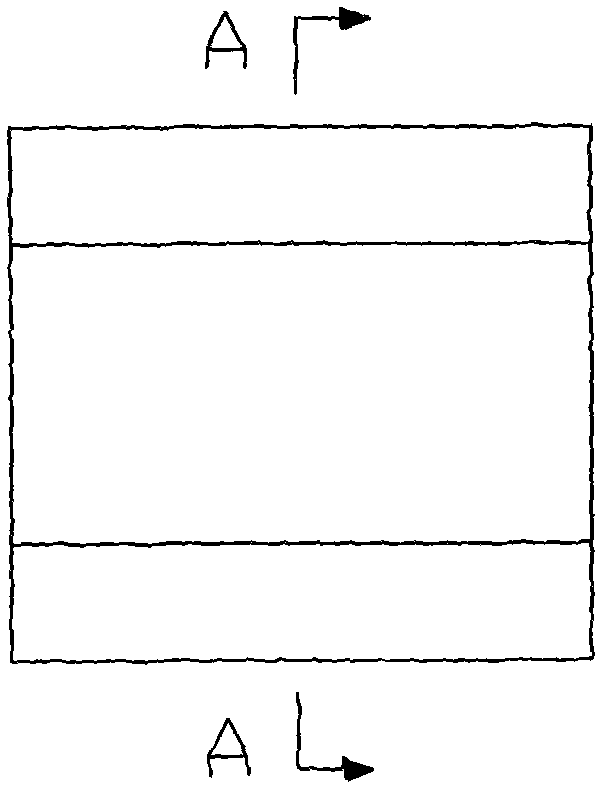

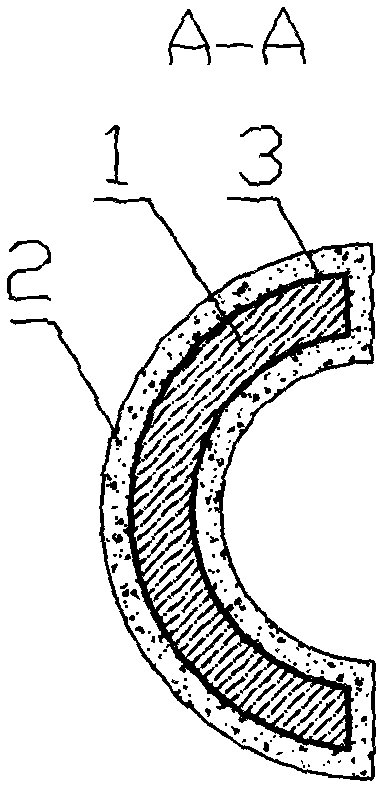

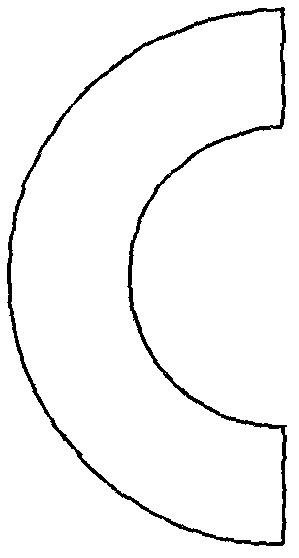

[0040] Embodiment 1 A kind of special-shaped external wall insulation board such as Figure 1 to Figure 3 As shown, the cross-section is arc-shaped.

[0041] The outer wall thermal insulation board with an arc-shaped cross section includes an arc-shaped vacuum heat insulation board, and the arc-shaped vacuum heat insulation board is made of an arc-shaped inorganic heat preservation core material board 1 and is covered with a vacuum insulation board. The thermal bag 3 is composed of an arc-shaped vacuum insulation panel covered with a shell 2 made of inorganic heat-insulating material, and the arc-shaped inorganic heat-insulating core board 1 is made of inorganic fiber material, and the inorganic fiber material is rock wool or Glass fiber, the material of the protective shell 2 formed by the inorganic heat-resisting material is foamed cement.

[0042] The method of the present invention's production embodiment 1 arc-shaped outer wall insulation board, as Figure 8 to Figure 1...

Embodiment 2

[0057] Embodiment 2 A kind of special-shaped external wall insulation board such as Figure 4 to Figure 7 As shown, the cross-section of the external wall insulation board is L-shaped.

[0058] The production method of embodiment 2 is identical with the production method of embodiment 1, and embodiment 2 is compared with embodiment 1, only the shape of vacuum insulation board and mold inner cavity is different, as Figure 18 to Figure 19 shown.

[0059] The cross-section of the special-shaped external wall insulation board of the present invention is not only arc-shaped or L-shaped, but also other special-shaped geometric shapes can be adopted according to the needs of building components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com