Corrosion-resistant cable bridge plate and corrosion-resistant cable bridge assembled by same

A cable tray, corrosion-resistant technology, used in electrical components and other directions, can solve the problems of easy aging, easy deformation, easy corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of the corrosion-resistant cable bridge plate comprises the following steps:

[0041] S1. Prepare the corrosion-resistant cable bridge plate mold, put the welded steel skeleton into the mold, and set aside;

[0042] S2. Stir and mix the raw materials of the ultra-high-performance concrete in proportion to obtain the ultra-high-performance concrete mixture, and pour it into the mold prepared in step S1, and then perform vibration molding to flatten the surface;

[0043] S3. Cover the cover plate prepared in step S2 with a moisturizing film, remove the mold after curing at room temperature for 24 hours, then perform thermal curing in an environment of 65-85° C. for 24-48 hours, and obtain a corrosion-resistant cable bridge plate after cooling.

[0044] The prepared corrosion-resistant cable bridge plate has good insulation, reduces eddy current and heat generation of cables, good mechanical properties, good corrosion resistance, good durability, good ...

Embodiment 1

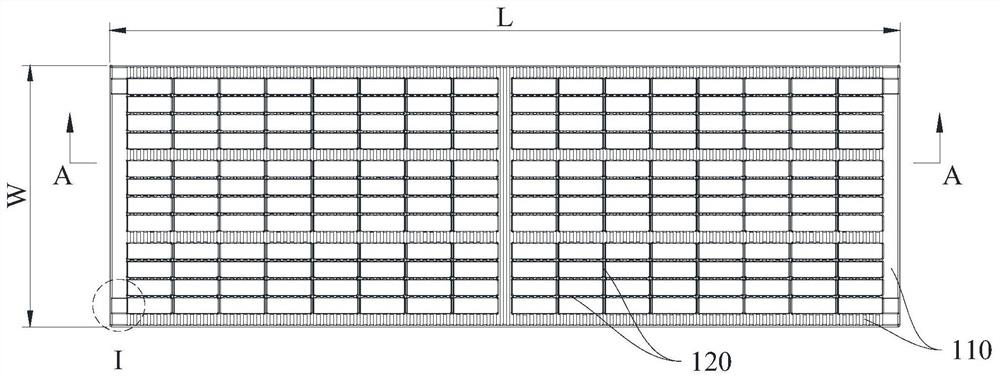

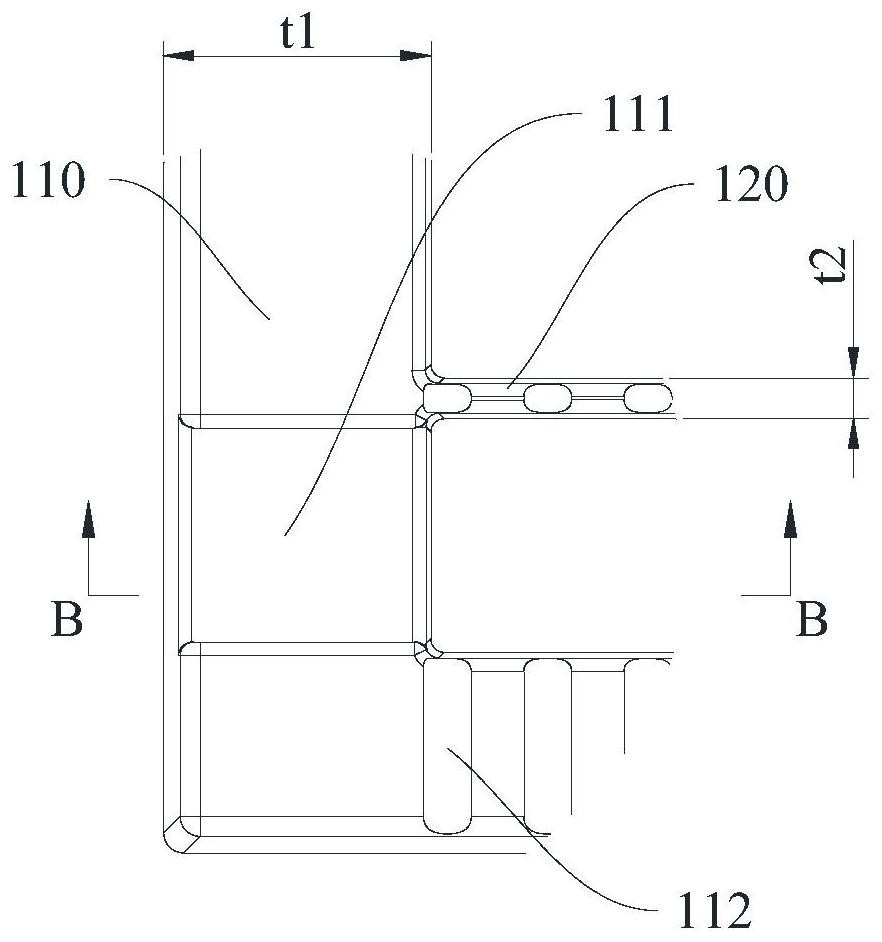

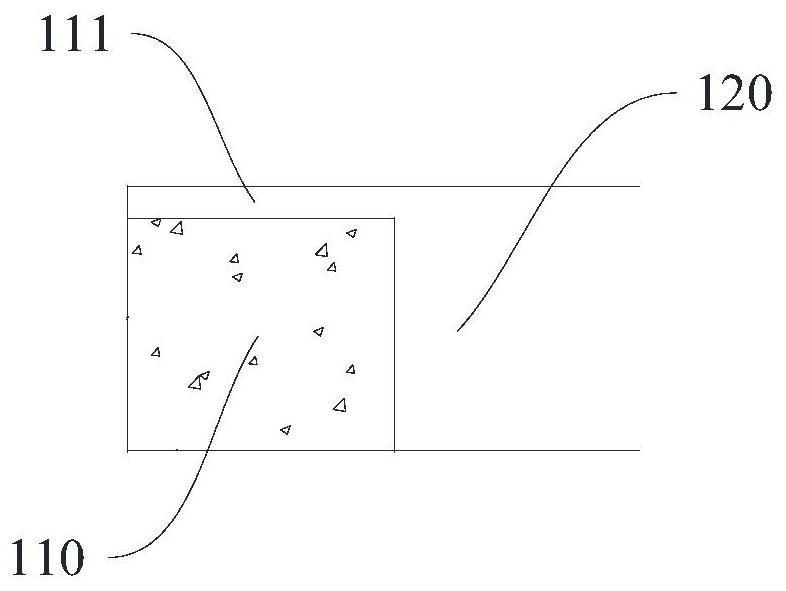

[0051] A corrosion-resistant cable bridge slab with a length of 1000mm, a width of 450mm, and a thickness of 30mm, which is an ultra-high-performance concrete grid structure, including 7 criss-cross main ribs, and 4 along the width direction of the corrosion-resistant cable bridge slab The other three are arranged at intervals along the length direction of the corrosion-resistant cable tray plate; these main ribs enclose and form 6 lattice rooms, and each lattice is provided with a number of criss-crossing auxiliary ribs. The wall thickness of these auxiliary ribs is It is smaller than the wall thickness of the main rib, where the wall thickness t1 of the main rib is 30mm, and the wall thickness t2 of the auxiliary rib is 10mm; The spacing in the width direction of the bridge plate is 30mm, and the hollow rate of the corrosion-resistant cable bridge plate is 50%. The main rib constituting the short side of the corrosion-resistant cable bridge plate is provided with a fastener ...

Embodiment 2

[0053] A corrosion-resistant cable tray slab with a length of 3000mm, a width of 650mm, and a thickness of 70mm, which is an ultra-high-performance concrete grid structure, including 7 criss-cross main ribs, and 4 along the width direction of the corrosion-resistant cable tray slab The other three are arranged at intervals along the length direction of the corrosion-resistant cable tray plate; these main ribs enclose and form 6 lattice rooms, and each lattice is provided with a number of criss-crossing auxiliary ribs. The wall thickness of these auxiliary ribs is The wall thickness of the main rib is smaller than that of the main rib, where the wall thickness t1 of the main rib is 50mm, and the wall thickness t2 of the auxiliary rib is 30mm; the distance between two adjacent auxiliary ribs in the length direction of the corrosion-resistant cable bridge plate is 200mm. The spacing in the width direction of the bridge plate is 80mm, and the hollow rate of the corrosion-resistant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com