Vacuum energy vortex steam condenser

A condenser and vortex technology, applied in the direction of machines/engines, engine components, mechanical equipment, etc., can solve the problems of high plant power consumption, large power consumption, and low thermal efficiency, and achieve reduced plant power consumption, stable operation, and The effect of high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

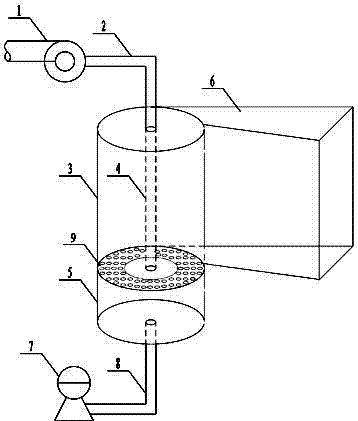

[0016] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0017] Vacuum energy vortex condenser, such as figure 1 As shown, it includes a vortex generating chamber 3 and a condensed water collecting chamber 5 . The vortex generating chamber 3 is a cylindrical structure made of high-hardness alloy steel, and its outer wall is wrapped with heat insulating material. The condensate water collection chamber 5 is located at the lower part of the vortex generation chamber 3, and is a cylinder with the same diameter as the vortex generation chamber. The vortex generation chamber and the condensate water collection chamber are combined into a cylinder with the same diameter. The bottom wall of the vortex generation chamber Combined with the top wall of the condensed water collection chamber to form a middle partition 9, the middle partition 9 is located at the lower part of the entire cylinder, and the middle partition 9 is a ring-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com