Plasma ignition kiln drying device for anthracite kiln

A technology of plasma ignition and anthracite, applied in the field of pulverized coal kiln, can solve the problems of wasting high-quality energy, long ignition time, large smoke and dust, etc., and achieve the effect of low production cost, strong capacity and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

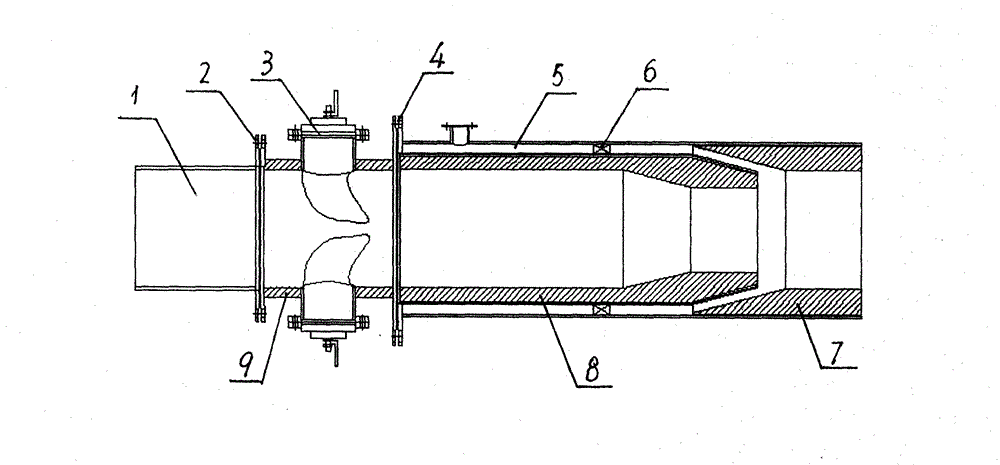

[0009] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A plasma ignition drying device for an anthracite kiln, the primary air pulverized coal pipe 1, the seat body 9, and the first-stage thermal cracker 8 are sequentially connected in series through the flange A 2 and the flange B 4, and the second-stage thermal cracker The device 7 is sleeved on the outer part of the primary thermal cracker 8, and it is contained as a whole, and the peripheral air pulverized coal formed between the inner wall of the secondary thermal cracker 7 and the outer wall of the primary thermal cracker 8 The swirl vane 6 is installed in the pipeline 5, the outer surface of the tail end of the primary thermal cracker 8 and the inner surface of the tail side are respectively in the shape of an outer cone and an inner cone in the same direction. There is an inner conical structure matching the outer conical shape of the tail end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com