Off-focus value measuring method for phase diversity wavefront sensor

A technology of wavefront sensor and measurement method, which is applied in the field of defocus measurement, can solve problems such as inability to correctly detect wavefront and restore images, difficult to use defocus measurement technology, and complicated measurement method mechanism, so as to overcome the inability to measure accurately Optical path difference, accurate measurement of system defocus, simple and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

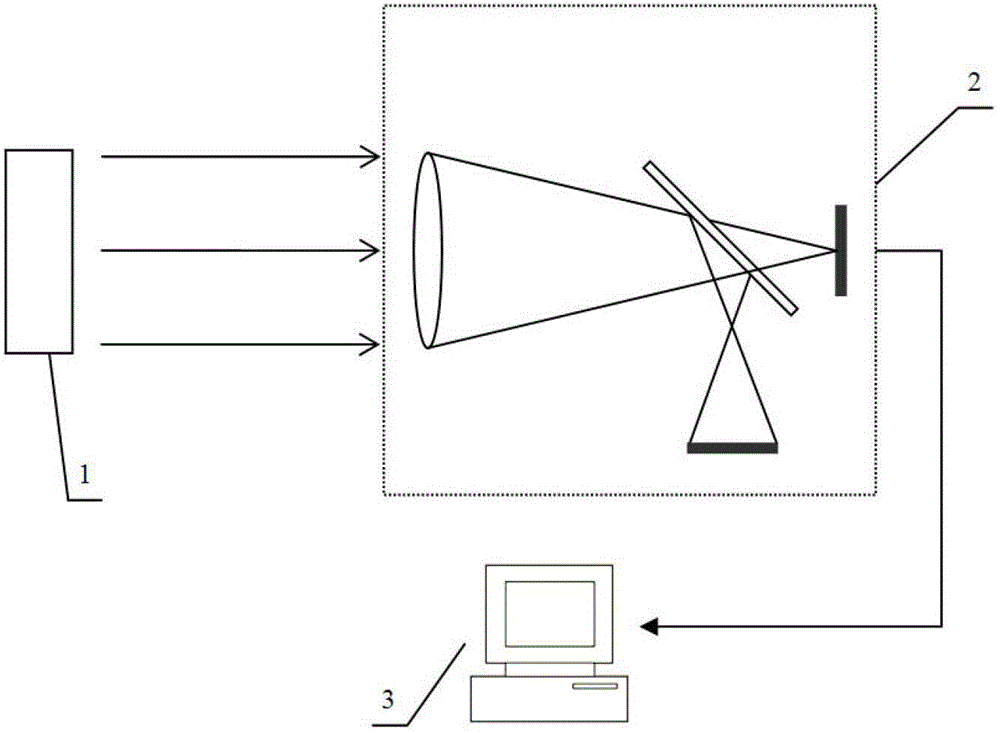

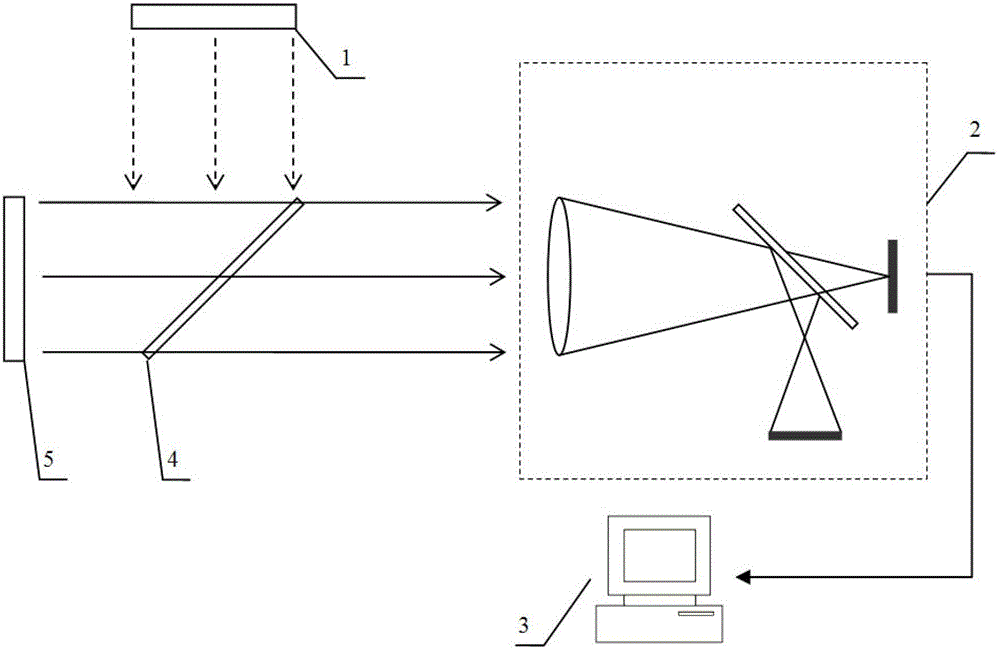

[0025] Such as figure 1 As shown, the plane light wave emitted by the parallel light source 1 is incident on the PD WFS 2; the PD WFS 2 collects the out-of-focus surface spot image and transmits it to the processing system 3; after the processing system 3 obtains the out-of-focus surface far-field spot image The algorithm calculates the amount of defocus of the system.

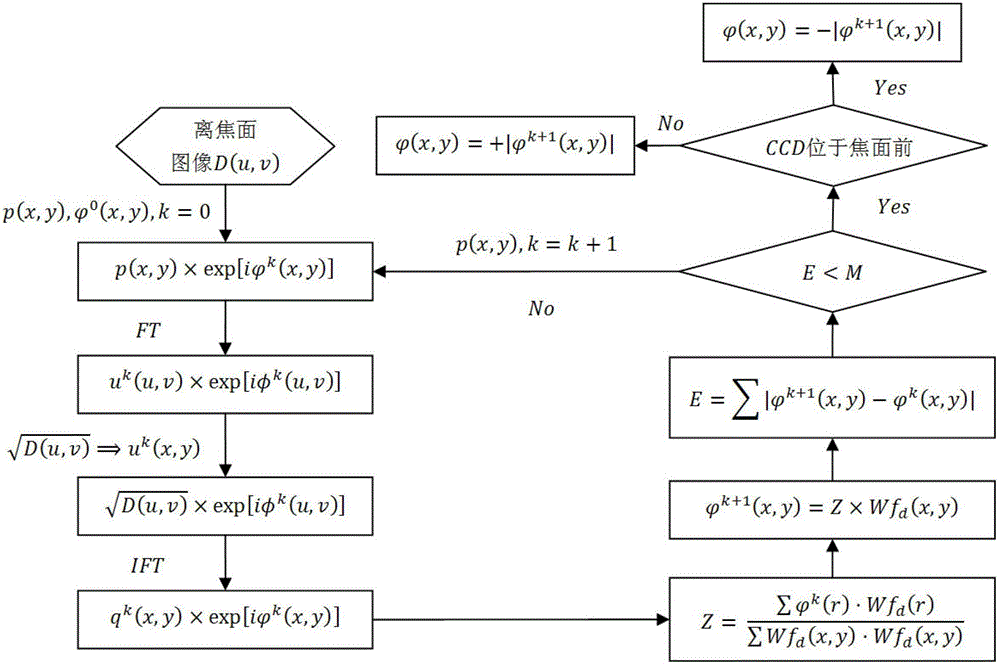

[0026] Such as figure 2 As shown, the defocus amount calculation algorithm starts from obtaining the far-field spot image D(u,v) of the defocus plane, where u,v are the coordinates of the image function definition domain, and the steps are as follows:

[0027] (1) Set loop variable k=0, generalized pupil function p(x,y)=1, initial defocused wavefront It can be any random number, and the pupil surface complex amplitude function is constructed according to the above parameters x, y are the domain coordinates of the wave surface function, and i is the imaginary unit

[0028] (2) Apply Fourier transform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com