Method for measuring solution and precipitation temperatures of precipitated phase in steel by adopting dilation method

A technology of iron and steel materials and precipitation temperature, which is applied in the field of measurement of precipitation phase dissolution, dissolution, precipitation temperature and precipitation temperature in steel materials by expansion method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

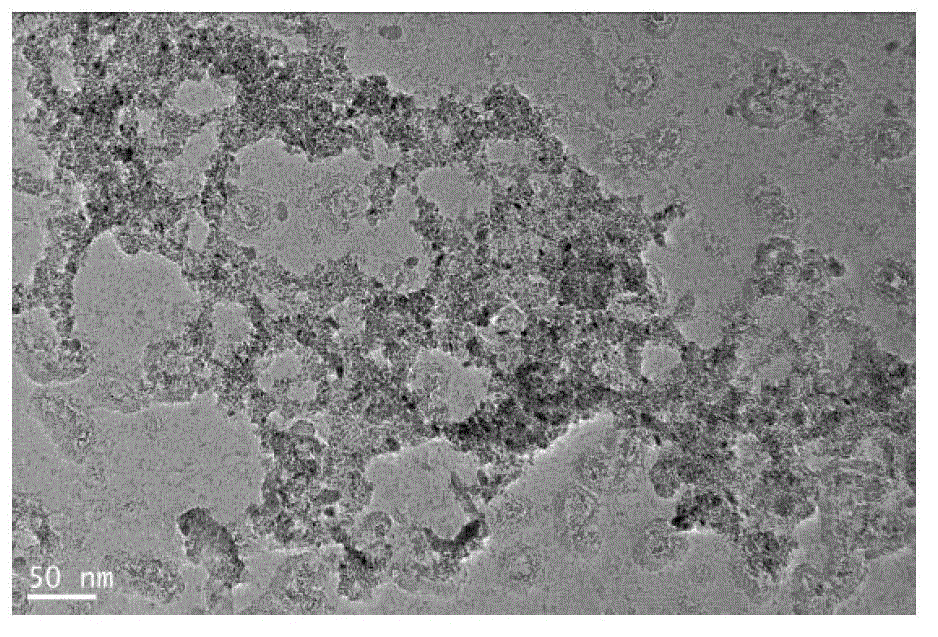

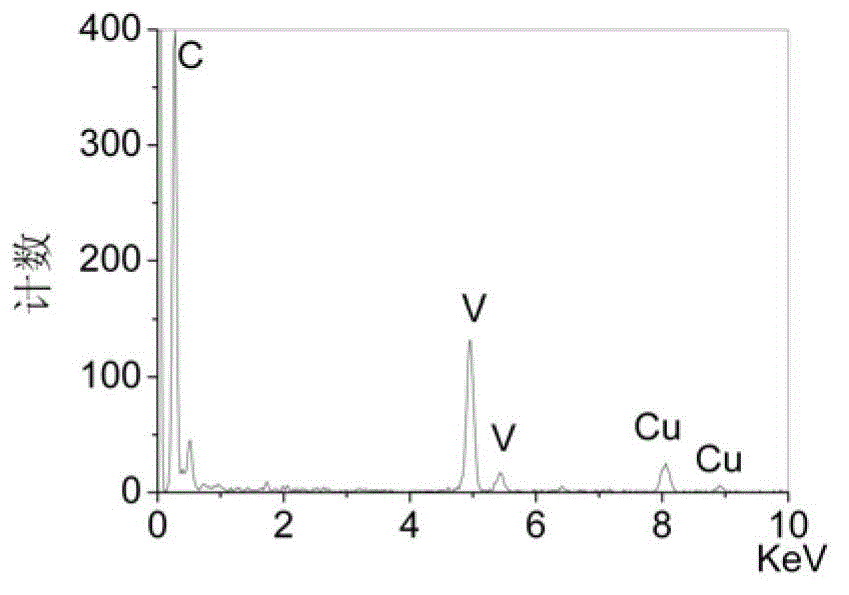

Image

Examples

Embodiment 1

[0036] The measurement of embodiment 1 VC melting temperature

[0037] Sampling: Take a certain V-added steel and process it into a round bar of Ф4mm×25mm. The steel composition is shown in the table below:

[0038]

[0039] Ultrasonic cleaning with alcohol solution for 2 minutes, and wait for the sample to dry before use.

[0040] (2) Measure the expansion coefficient and draw the curve:

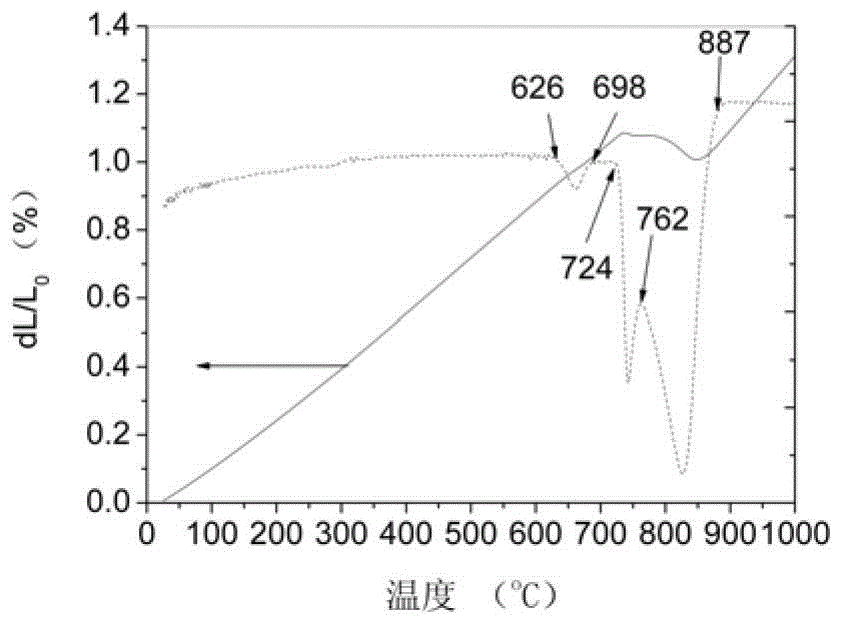

[0041] Temperature measuring range: 30~1000°C; heating and cooling rate: 5°C / min. Argon protective atmosphere. Temperature in the heating process - expansion (dL / L 0 ) change curve and its primary differential results such as figure 1 shown. The solid line is the expansion-temperature curve, and the dotted line is the first differential result. The temperature at each transition point has been marked in figure 1 middle.

[0042] (3) Data analysis

[0043] from figure 1From the primary differential curve, it can be seen that there is a weak volume change process at 626-698°C du...

Embodiment 2

[0048] Embodiment 2 TiC precipitation temperature measurement

[0049] (1) Sampling: Take a Ti-added steel and process it into a round bar of Ф4mm×25mm. The steel composition is shown in the table below:

[0050]

[0051] Ultrasonic cleaning with alcohol solution for 2 minutes, and wait for the sample to dry before use.

[0052] (2) Dilatometer test and draw the curve:

[0053] Temperature measuring range: 30~1300°C; heating and cooling rate: 3°C / min. Only the cooling process is studied here, the temperature-expansion (dL / L0) change curve and its first differential results are as follows: Image 6 shown. The temperature at each transition point has been marked in Image 6 middle.

[0054] (3) Data analysis:

[0055] Judging from the iron-carbon phase diagram, austenite begins to transform into ferrite at 797.5°C. The transformation reaction of austenite at 749.5~739.5℃ is affected by another reaction process. The transformation from austenite to pearlite begins at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com