Stem and leaf separating machine for mechanically picked fresh leaves

A technology for separating stems and leaves and fresh leaves, which is applied in the field of agricultural machinery and automation control to achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

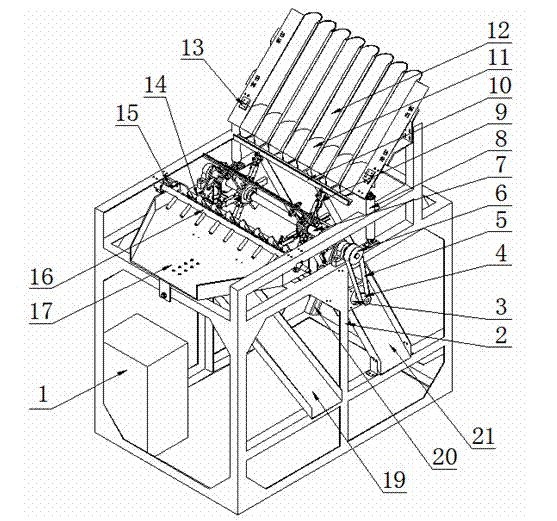

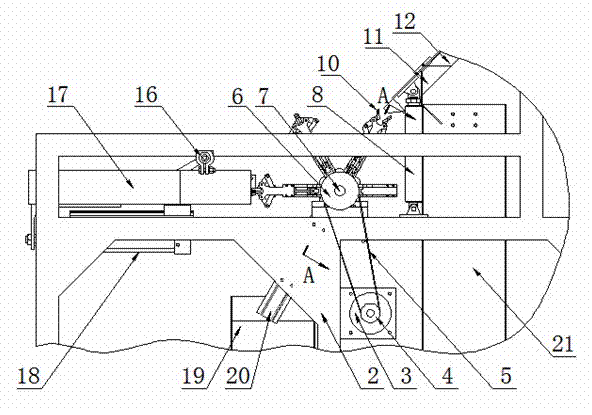

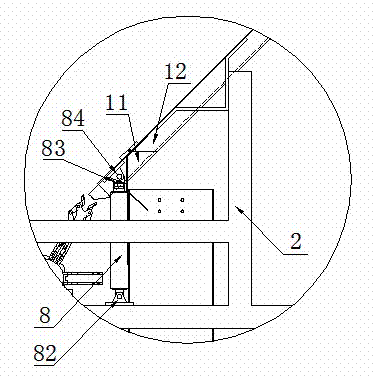

[0034] The present invention will be further described below with reference to the accompanying drawings.

[0035] Such as Figures 1 to 12 As shown, the stalk leaf separator of machine-picked fresh leaves of the present invention mainly includes a controller 1, a frame 2, an inclined feeding plate (including a lower feeding plate 11 and an upper feeding plate 12), a first rotating drive mechanism, The third rotary drive mechanism, the main shaft 7, the clamping mechanism 9, the second rotary drive mechanism, the blade opening and closing mechanism 14, the fourth rotary drive mechanism, the leaf outlet groove 17, the reciprocating movement mechanism and the cleaning air pipe 16 and other parts.

[0036] As a relatively simple and easy implementation of the present invention, the first rotation drive mechanism can be the first cylinder 8, the cylinder body of the first cylinder 8 is hinged with the frame 2, and the piston rod of the first cylinder 8 is connected to the lower fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com