Method for preparing directionally-crystallized rare-earth ultra-magnetostrictive alloys and directional crystallization device

A technology of directional crystallization and alloys, which is applied in the preparation of alloys and crucibles. It can solve the problems of expensive finished products, the inability to use crucibles to move downwards to directional solidify, and affect the application of materials, so as to achieve the effect of saving economic costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

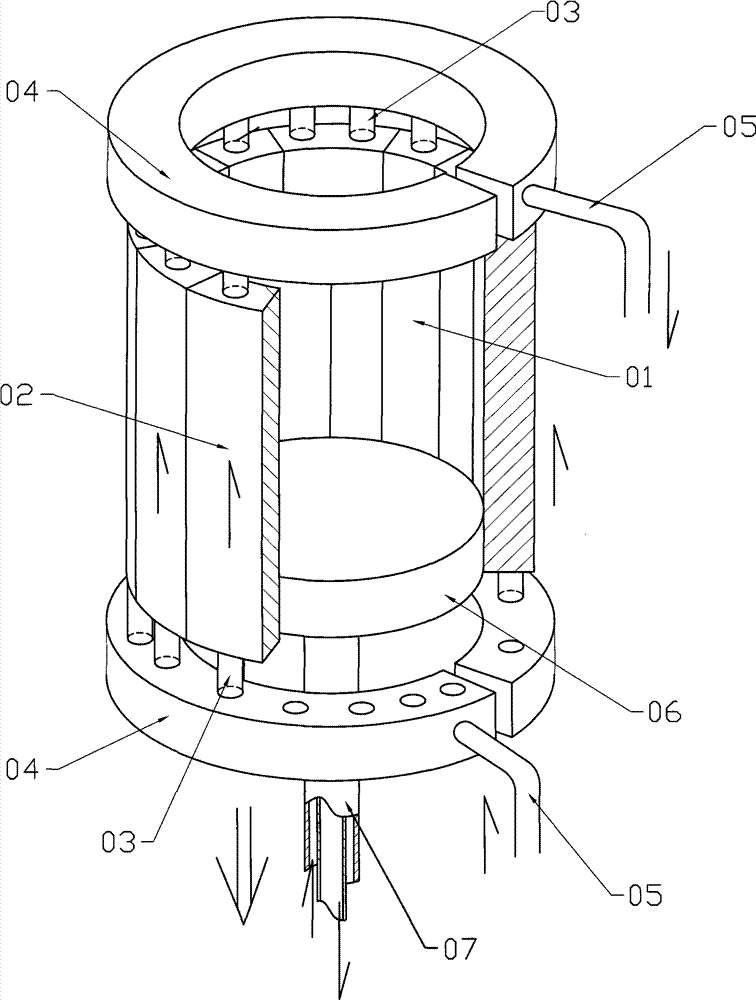

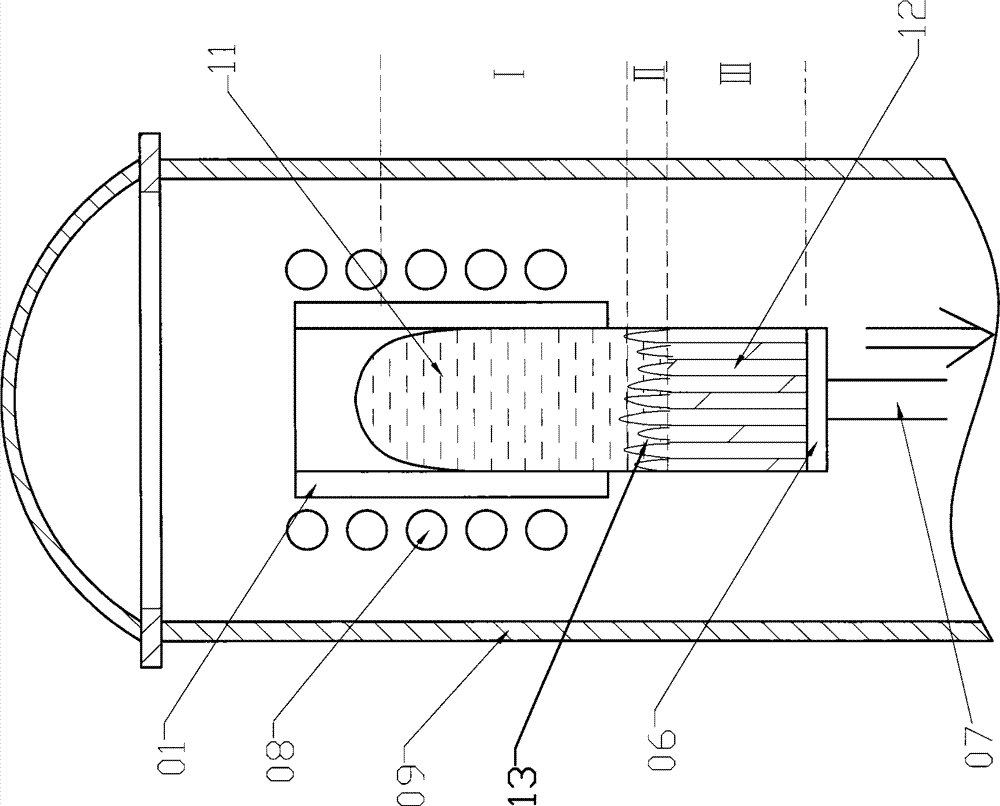

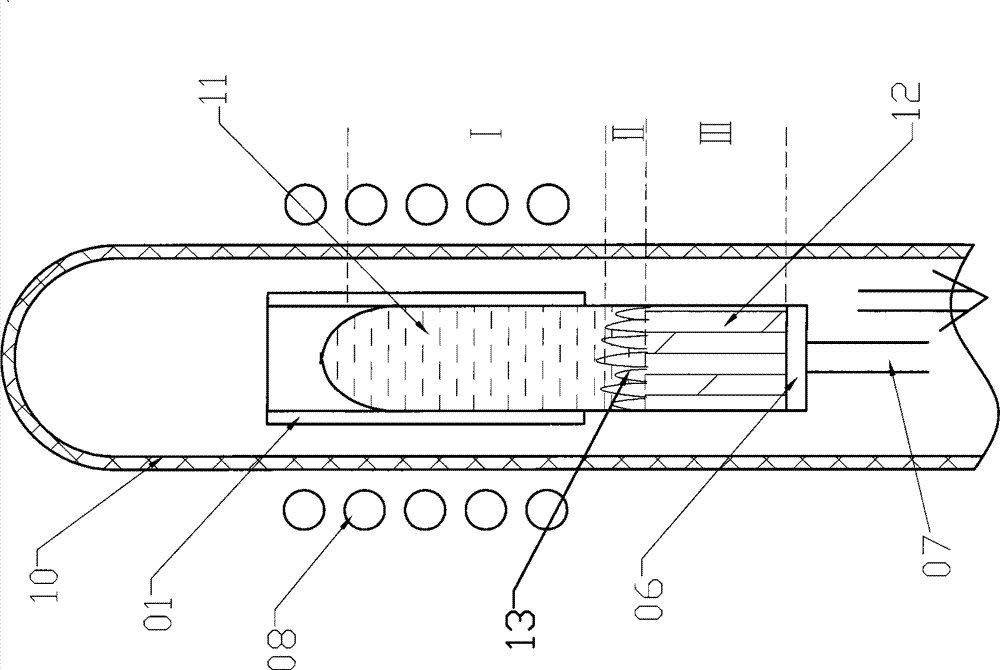

[0027] The technical points adopted by the present invention to solve its technical problems are mainly as follows:

[0028] 1. Basic device and process

[0029] The water-cooled copper crucible is used as the crucible for the directional solidification process, which is the basis of the present invention. In order to use the induction cold crucible technology for directional solidification, the invention changes the structure of the cold crucible suitable for the vacuum suspension melting technology. The so-called water-cooled copper crucible is a copper crucible divided into several petals along the direction parallel to the crucible axis, and circulating cooling water is passed through each petal. In principle, any crucible meeting these requirements can be used for melting. However, the present invention requires that the bottom of the crucible has a separate structure from the wall of the crucible. Preferably, it has a water passage for cooling the bottom of the crucible ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com