Anti-seepage air-permeable brick and manufacturing method thereof

A technology of air-permeable bricks and micro-pores, which is applied to ceramic products, other household appliances, and other household appliances. It can solve problems affecting the rapid turnover of ladles, shortened lifespan, and ablation of air-permeable bricks, so as to improve thermal shock stability and service life. Life, the effect of avoiding infiltration and steel slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

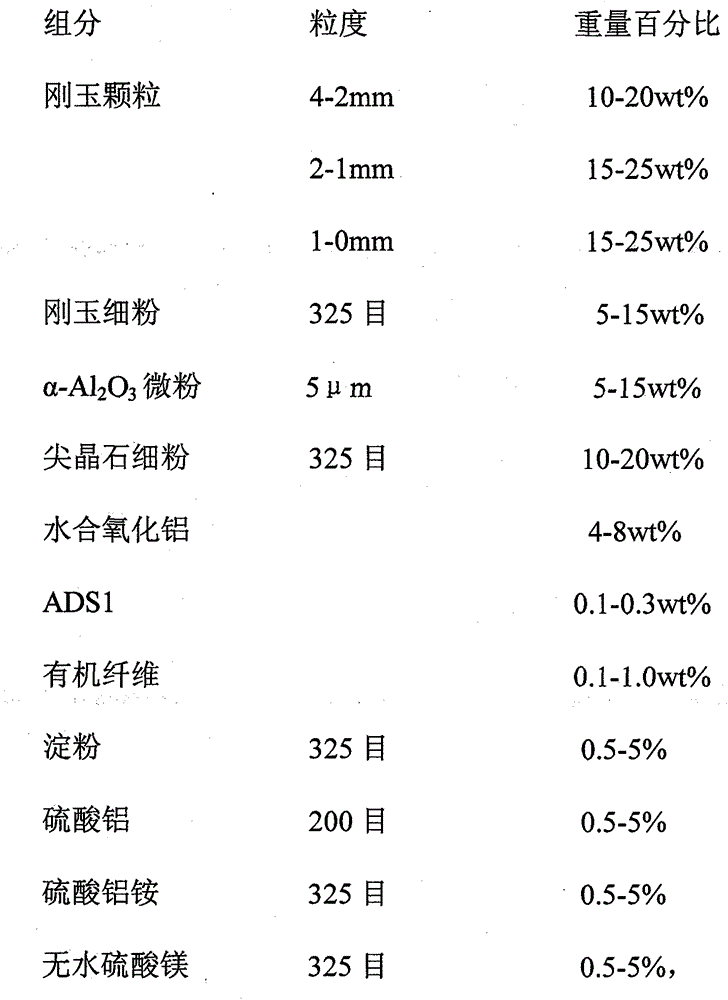

[0036] Air brick formula:

[0037] Component Particle Size Content (weight ratio)

[0038] White corundum particles 4-2mm 12%

[0039] 2-1mm 22%

[0040] 1-0mm 21%

[0041] Tabular corundum fine powder 325 mesh 10%

[0042] α-Al 2 o 3 Micropowder 5μm 10%

[0043] Spinel fine powder 325 mesh 15%

[0044] Hydrated Aluminum Oxide 5%

[0045] Starch 325 mesh 1%

[0046] Aluminum sulfate 325 mesh 2%

[0047] Anhydrous magnesium sulfate 325 mesh 2%

[0048] Organic Fiber 0.5%

[0049] ADS1 0.2%

[0050] The manufacturing method of this embodiment includes the following steps:

[0051] The first step: prepare raw materials according to the formula, and inspect the raw materials according to the national standard, and put them into use after passing the inspection;

[0052] The second step: the fine powder part in the formula, including tabular corundum fine powder, α-Al 2 o 3 Micropowder, spinel powder, hydrated alumina, starch,...

Embodiment 2

[0062] Air brick formula:

[0063] Component Particle Size Content (weight ratio)

[0064] Tabular alumina particles 4-2mm 12%

[0065] 2-1mm 22%

[0066] 1-0mm 21%

[0067] White corundum fine powder 325 mesh 12%

[0068] α-Al 2 o 3 Micropowder 5μm 8%

[0069] Spinel fine powder 325 mesh 15%

[0070] Hydrated Aluminum Oxide 5%

[0071] Starch 325 mesh 1%

[0072] Aluminum ammonium sulfate 325 mesh 2%

[0073] Anhydrous magnesium sulfate 325 mesh 2%

[0074] Organic Fiber 0.5%

[0075] ADS1 0.2%

[0076] The manufacturing method of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0078] Air brick formula:

[0079] Component Particle Size Content (weight ratio)

[0080] Dense corundum particles 4-2mm 12%

[0081] 2-1mm 23%

[0082] 1-0mm 20%

[0083] Tabular corundum fine powder 325 mesh 12%

[0084] α-Al 2 o 3 Micropowder 5μm 8%

[0085] Spinel fine powder 325 mesh 15%

[0086] Hydrated Aluminum Oxide 5%

[0087] Starch 325 mesh 1.5%

[0088] Aluminum ammonium sulfate 325 mesh 1.5%

[0089] Anhydrous magnesium sulfate 325 mesh 2%

[0090] Organic Fiber 0.5%

[0091] ADS1 0.2%

[0092] The manufacturing method of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com