Method for preparing copolymer chlorohydrin rubber by precipitation polymerization

A chlorohydrin rubber and precipitation polymerization technology, applied in the field of chlorohydrin rubber, can solve the problems of unsatisfactory production cost of chlorohydrin rubber, and achieve the effects of excellent mechanical properties, beautiful appearance and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

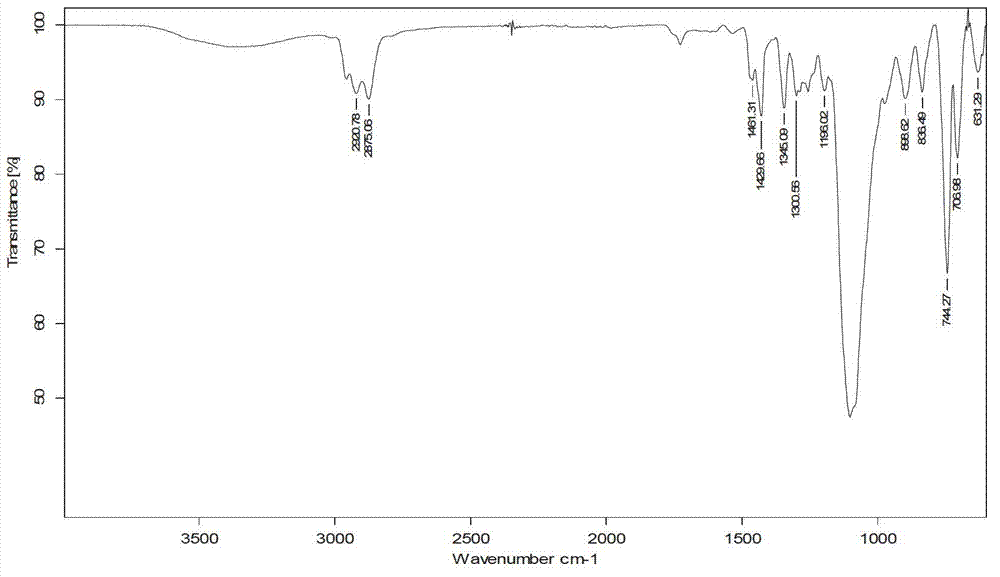

Image

Examples

Embodiment 1

[0015] Mix 65 parts by volume of petroleum ether, 12 parts by volume of a mixture of epichlorohydrin and ethylene oxide, and 2.8 parts by volume of catalyst, and react at 70°C under nitrogen atmosphere After 3 hours, the heating reaction was stopped, and after cooling with cold water, the solvent was vacuumed to obtain an elastomer, and vacuum-dried at 50° C. to obtain a pale yellow to light white granular homopolychlorohydrin rubber 1. The volume of epichlorohydrin is 8 parts, and the volume of ethylene oxide is 4 parts. The catalyst is triisobutylaluminum, phosphoric acid and N,N-dimethylaniline in a volume ratio of 100:200:16. The intrinsic viscosity [η] of the homopolychlorohydrin rubber 1 is 0.2734; the viscosity-average molecular weight of the product is M η is 75988.

Embodiment 2

[0017] Mix 10 parts by volume of n-heptane, 5 parts by volume of a mixture of epichlorohydrin and ethylene oxide, and 1 part by volume of a catalyst, under a nitrogen atmosphere at 50°C After reacting for 1 hour, the heating reaction was stopped, and after cooling with cold water, the solvent was vacuumed out to obtain an elastomer, and vacuum-dried at 55° C. to obtain a slightly yellow to light white granular homopolychlorohydrin rubber 2. The volume of epichlorohydrin is 2.8 parts, and the volume of ethylene oxide is 2.2 parts. The catalyst is triisobutylaluminum, phosphoric acid and N,N-dimethylaniline in a volume ratio of 80:200:24.

Embodiment 3

[0019] Mix 70 parts by volume of n-hexane, 16 parts by volume of a mixture of epichlorohydrin and ethylene oxide, and 5 parts by volume of catalyst, and react at 80°C under nitrogen atmosphere After 5 hours, the heating reaction was stopped, and after cooling with cold water, the solvent was vacuumed out to obtain an elastomer, and vacuum-dried at 60° C. to obtain a slightly yellow to light white granular homopolychlorohydrin rubber 3. The volume of epichlorohydrin is 10 parts, and the volume of ethylene oxide is 6 parts. The catalyst is triisobutylaluminum, phosphoric acid and N,N-dimethylaniline in a volume ratio of 100:160:12.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com