Nylon composite, preparation method, application thereof and plastic product of nylon composite

A nylon composite material and nylon technology, which is applied in the field of nylon composite materials and plastic products, can solve the problems of accumulation of static electricity, hidden dangers, and high surface resistivity of nylon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

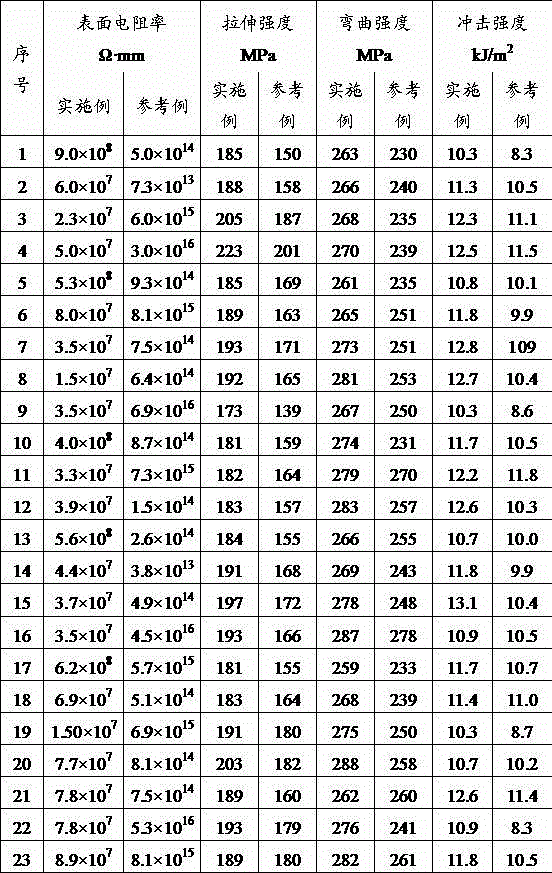

Examples

Embodiment 1

[0065] Take 3 parts of carbon nanotube conductive fibers and 0.1 part of silane coupling agent and put them into the mixer. The carbon nanotube conductive fibers include carbon nanotubes with a mass ratio of 0.1 part, 0.1 parts of dispersant and 100 parts of thermoplastic elastomer SBS; The dispersant is alkylbenzene sulfonate CH 3 (CH 2 ) 2 C 6 h 4 SO 3 Li 2 , Stir evenly, heat up and stir, add 3 parts of calcium stearate, 3.5 parts of polyphenol antioxidant 1010 and 2.8 parts of compatibilizer JX-10 after stirring, stir at low speed, open the cooling water of the mixer at the same time to cool, add 0.3 parts after cooling 1 part of polydecanediamine sebacate (nylon 1010) and 67.7 parts of polyparaphenylene terephthalamide (PPTA) were stirred at a low speed, and finally extruded and granulated in a twin-screw extruder after cooling, pelletizing, Just dry.

[0066] The surface resistivity of the nylon composite material that present embodiment 1 makes is measured under ...

Embodiment 2

[0068] Take 20 parts of carbon nanotube conductive fibers and 0.1 part of silane coupling agent and put them into a mixer, the carbon nanotube conductive fibers include carbon nanotubes with a mass ratio of 0.1 part, 0.1 parts of dispersant and 100 parts of thermoplastic elastomer SEBS; The dispersant is alkylbenzene sulfonate CH 3 (CH 2 ) 2 C 6 h 4 SO 3 Li, after stirring evenly, heat up and stir. After stirring, add 3 parts of calcium stearate, 3.5 parts of polyphenol antioxidant 1010 and 2.8 parts of compatibilizer JX-10 and stir at a low speed. At the same time, turn on the cooling water of the mixer for cooling. After cooling, add 0.3 parts of polydecanediamine sebacate (nylon 1010) and 67.7 parts of polyparaphenylene terephthalamide (PPTA) are stirred at low speed, and finally extruded and granulated in a twin-screw extruder, cooled and pelletized , dry it.

[0069] The surface resistivity of the nylon composite material that present embodiment 2 makes is measured ...

Embodiment 3

[0071] Take 25 parts of carbon nanotube conductive fibers and 0.1 part of silane coupling agent and put them into the mixer. The carbon nanotube conductive fibers include carbon nanotubes with a mass ratio of 0.1 part, 0.1 parts of dispersant and 100 parts of thermoplastic elastomer SIS; The dispersant is alkylbenzene sulfonate CH 3 (CH 2 ) 5 C 6 h 4 SO 3 (NH 4 ) 2 , Stir evenly, heat up and stir, add 3 parts of calcium stearate, 3.5 parts of polyphenol antioxidant 1010 and 2.8 parts of compatibilizer JX-10 after stirring, stir at low speed, open the cooling water of the mixer at the same time to cool, add 0.3 parts after cooling 1 part of polydecanediamine sebacate (nylon 1010) and 67.7 parts of polyparaphenylene terephthalamide (PPTA) were stirred at a low speed, and finally extruded and granulated in a twin-screw extruder after cooling, pelletizing, Just dry.

[0072] The surface resistivity measured under ASTM D257 conditions of the nylon composite material that pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com