Ceramic tiles with anti-static effect and preparation method thereof

An anti-static and ceramic tile technology, applied in the ceramic tile field, can solve the problems of poor wear resistance of anti-static composite floor, high cost of veneer and PVC board, and heavy steel floor, so as to prevent equipment failure, improve anti-static effect, guarantee The effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

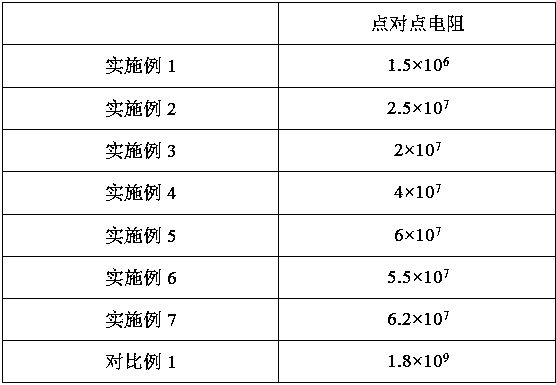

Examples

Embodiment 1

[0030] A kind of ceramic tile with anti-static effect, the bottom glaze and the top glaze are glazed on the ceramic tile body successively in the way of pouring glaze; it is fired in a kiln at a firing temperature of 900~950°C and a firing time of 50~60min. get tiles;

[0031] The surface glaze includes 75 parts by mass of frit, 4 parts by mass of conductive powder, 12 parts by mass of kaolin, 4 parts by mass of aluminum oxide, 6 parts by mass of zinc oxide, and 2 parts by mass of zirconium silicate;

[0032] The preparation method of the surface glaze comprises: uniformly mixing frit, conductive powder, kaolin, aluminum oxide, zinc oxide and zirconium silicate, wet ball milling, and sieving to obtain the surface glaze slurry.

[0033] The conductive powder comprises 55 parts by mass of graphene, 15 parts by mass of ceramic microspheres, 2 parts by mass of di-tertiary peroxide, 2 parts by mass of alkylamine, and 1 part by mass of emulsifier;

[0034] The preparation method of...

Embodiment 2

[0045] A kind of ceramic tile with anti-static effect, the bottom glaze and the top glaze are glazed on the ceramic tile body successively in the way of pouring glaze; it is fired in a kiln at a firing temperature of 900~950°C and a firing time of 50~60min. get tiles;

[0046] The surface glaze includes 70 parts by mass of frit, 3 parts by mass of conductive powder, 10 parts by mass of kaolin, 3 parts by mass of aluminum oxide, 5 parts by mass of zinc oxide, and 1 part by mass of zirconium silicate;

[0047] The preparation method of the top glaze comprises: uniformly mixing frit, conductive powder, kaolin, aluminum oxide, zinc oxide and zirconium silicate, wet ball milling, and sieving to obtain the top glaze slurry.

[0048] The conductive powder comprises 50 parts by mass of graphene, 10 parts by mass of ceramic microspheres, 1 part by mass of di-tertiary peroxide, 1 part by mass of alkylamine, and 0.5 parts by mass of emulsifier;

[0049] The preparation method of the condu...

Embodiment 3

[0059] A kind of ceramic tile with anti-static effect, the bottom glaze and the top glaze are glazed on the ceramic tile body successively in the way of pouring glaze; it is fired in a kiln at a firing temperature of 900~950°C and a firing time of 50~60min. get tiles;

[0060] The surface glaze comprises 80 parts by mass of frit, 5 parts by mass of conductive powder, 20 parts by mass of kaolin, 5 parts by mass of aluminum oxide, 8 parts by mass of zinc oxide, and 3 parts by mass of zirconium silicate;

[0061] The preparation method of the surface glaze comprises: uniformly mixing frit, conductive powder, kaolin, aluminum oxide, zinc oxide and zirconium silicate, wet ball milling, and sieving to obtain the surface glaze slurry.

[0062] The preparation method of described graphene is:

[0063] Get 25 mass parts of graphite oxide, 3 mass parts of ethylenediamine, 1.5 mass parts of urea, 0.5 mass part of palladium dichloride, 0.05 mass part of sodium borohydride;

[0064] Add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com