Anti-static carbon-series coating and production process thereof

An anti-static, carbon-based technology, used in polyester coatings, polyether coatings, epoxy resin coatings, etc., can solve the problems of static electricity, no anti-static, unpleasant odor, etc., and achieve good anti-static effect. The effect of preventing unpleasant smell and improving the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

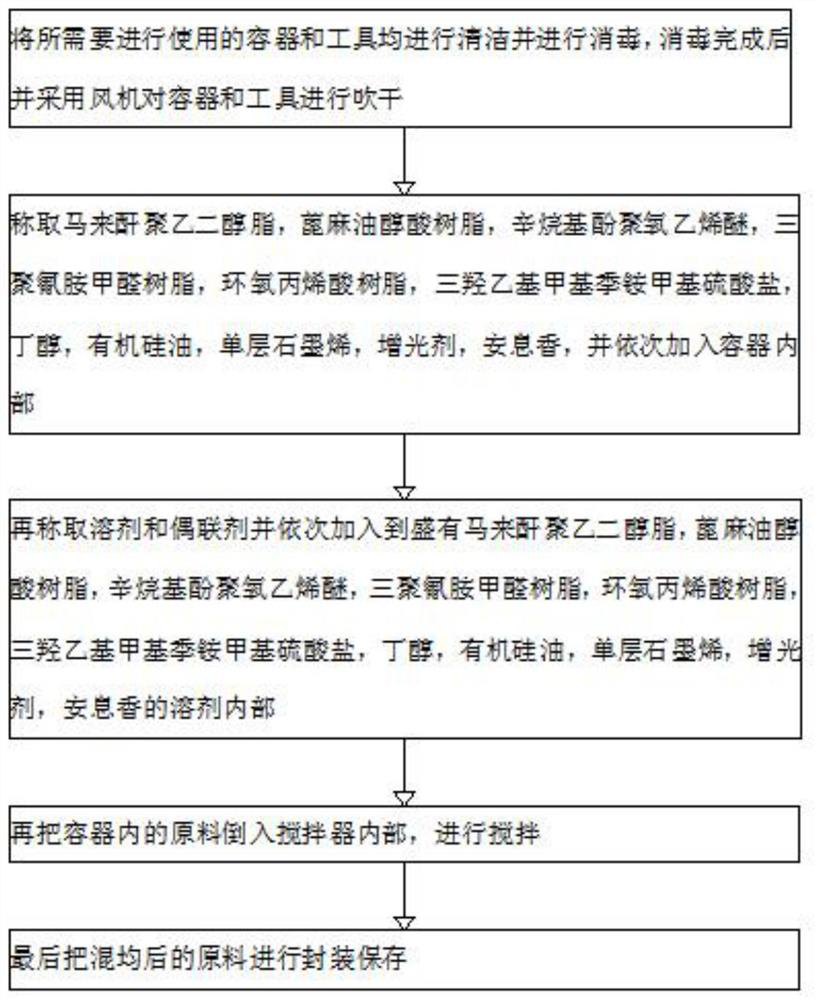

[0021] refer to figure 1 , an antistatic carbon-based coating and its production process, comprising the following raw materials in parts by weight: 25 parts of maleic anhydride polyethylene glycol resin, 40 parts of castor oil alkyd resin, and 18 parts of octylphenol polyoxyethylene ether , 20 parts of melamine formaldehyde resin, 30 parts of epoxy acrylic resin, 35 parts of trihydroxyethylmethyl quaternary ammonium methyl sulfate, 5 parts of butanol, 2 parts of organic silicone oil, 60 parts of solvent, 3 parts of coupling agent, single 0.3 parts of layered graphene, 12 parts of brightening agent, and 13 parts of benzoin.

[0022] In the present invention, the coupling agent is one or a combination of silane and titanate, and the solvent is water.

[0023] Among the present invention, a kind of antistatic carbon coating and production process thereof, the steps are as follows:

[0024] 1) Clean and disinfect the containers and tools that need to be used. After the disinfec...

Embodiment 2

[0032] refer to figure 1 , an antistatic carbon-based coating and a production process thereof, comprising the following raw materials in parts by weight: 20 parts of maleic anhydride polyethylene glycol resin, 35 parts of castor oil alkyd resin, and 20 parts of octylphenol polyoxyethylene ether , 18 parts of melamine formaldehyde resin, 28 parts of epoxy acrylic resin, 30 parts of trishydroxyethylmethyl quaternary ammonium methyl sulfate, 5 parts of butanol, 2 parts of silicone oil, 60 parts of solvent, 2 parts of coupling agent, single 0.5 parts of layered graphene, 15 parts of brightening agent, and 13 parts of benzoin.

[0033] In the present invention, the coupling agent is one or a combination of silane and titanate, and the solvent is water.

[0034] Among the present invention, a kind of antistatic carbon coating and production process thereof, the steps are as follows:

[0035] 1) Clean and disinfect the containers and tools that need to be used. After the disinfect...

Embodiment 3

[0043] refer to figure 1 , an antistatic carbon-based coating and its production process, comprising the following raw materials in parts by weight: 30 parts of maleic anhydride polyethylene glycol resin, 45 parts of castor oil alkyd resin, and 15 parts of octylphenol polyoxyethylene ether , 15 parts of melamine formaldehyde resin, 35 parts of epoxy acrylic resin, 40 parts of trihydroxyethylmethyl quaternary ammonium methyl sulfate, 7 parts of butanol, 3 parts of organic silicone oil, 60 parts of solvent, 4 parts of coupling agent, single 0.5 parts of layered graphene, 15 parts of brightening agent, and 13 parts of benzoin.

[0044] In the present invention, the coupling agent is one or a combination of silane and titanate, and the solvent is water.

[0045] Among the present invention, a kind of antistatic carbon coating and production process thereof, the steps are as follows:

[0046] 1) Clean and disinfect the containers and tools that need to be used. After the disinfecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com