High-solid-content white filling putty and preparation method thereof

A high-solid content, putty technology, applied in the field of paint fillers, can solve the problems of reducing the irritating odor and content of putty products, and achieve the effects of saving drying and polishing time, single variety, and excellent environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: White filling putty with high solid content and low odor

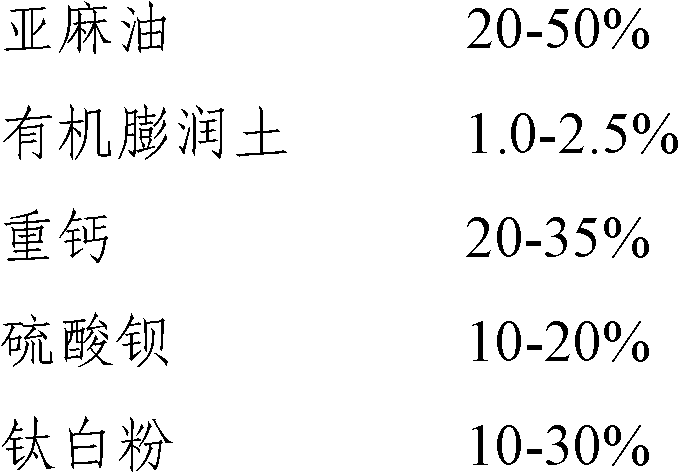

[0037] 1. The composition of raw materials is shown in Table 1.

[0038] Table 1

[0039] composition

Content (weight percent: 100%)

Linseed oil CS-100 (solid content 97%)

38.5

Organic bentonite FR-100C

1.5

Heavy calcium TP-1250 (particle size is 800 mesh)

25

Barium sulfate (particle size is 2500 mesh)

15

Titanium dioxide R996

20

[0040] 2. Preparation method:

[0041] 1) First add linseed oil CS-100 into the tank, then add organic bentonite FR-100C under the condition of stirring at 400r / min, stir evenly and increase the speed to 1500r / min for high-speed dispersion for 5 minutes;

[0042] 2) Under the stirring condition of 400r / min, add heavy calcium TP-1250, 2500 mesh barium sulfate, titanium dioxide R996 in turn, stir evenly, increase the speed to 1500r / min and disperse for 15 minutes to obtain the product.

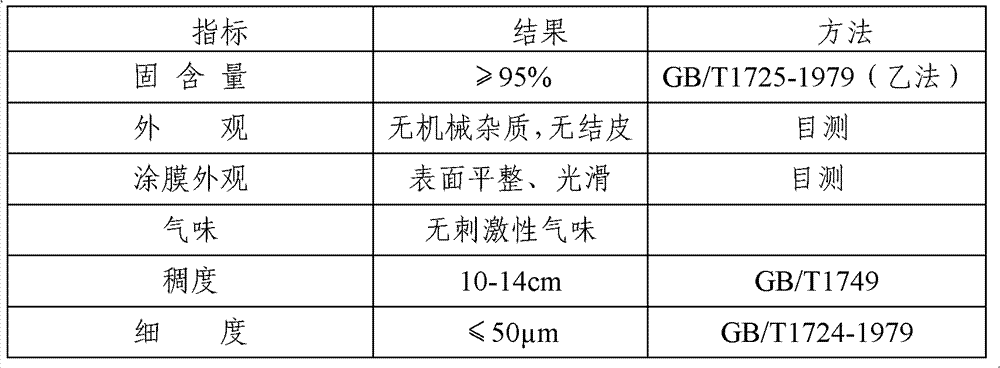

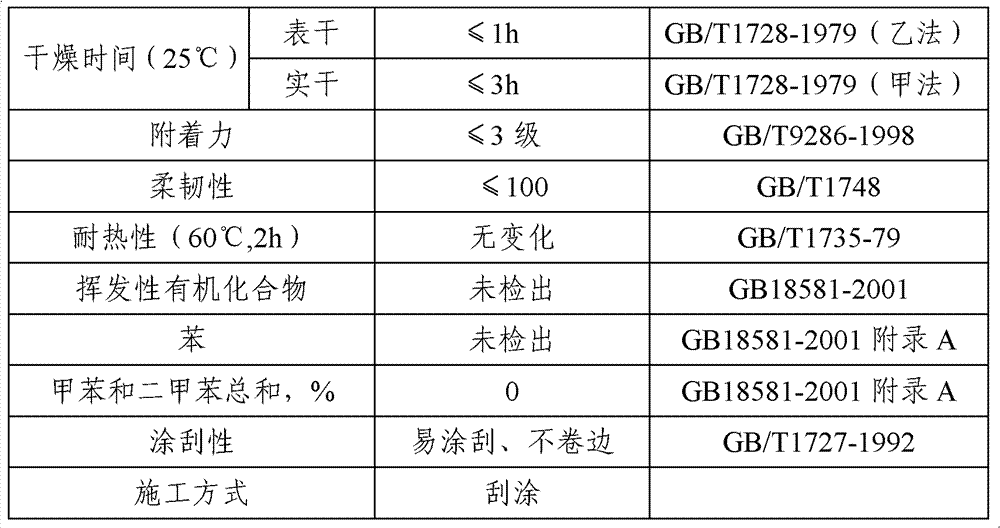

[...

Embodiment 2

[0050] 1. The composition of raw materials is shown in Table 3.

[0051] table 3

[0052] composition

Content (weight percent: 100%)

Linseed oil CS-100 (solid content 97%)

20

Organic bentonite FR-100C

2.5

Heavy calcium TP-1250 (particle size is 800 mesh)

35

Barium sulfate (particle size is 2500 mesh)

12.5

Titanium dioxide R996

30

[0053] 2. Preparation method:

[0054] 1) First add linseed oil CS-100 into the tank, then add organic bentonite FR-100C under 600r / min stirring condition, stir evenly and increase the speed to 1600r / min to disperse for 5 minutes;

[0055] 2) Under the stirring condition of 600r / min, add heavy calcium TP-1250, 2500 mesh barium sulfate, titanium dioxide R996 in turn, stir evenly, increase the speed to 1600r / min and disperse for 20 minutes to obtain the product.

[0056] 3. The test results are shown in Table 4.

[0057] Table 4

[0058]

[0059] It is required...

Embodiment 3

[0061] 1. The composition of raw materials is shown in Table 5.

[0062] table 5

[0063] composition

Content (weight percent: 100%)

Linseed oil CS-100 (solid content 97%)

50

Organic bentonite FR-100C

1

Heavy calcium TP-1250 (particle size is 800 mesh)

24

Barium sulfate (particle size is 2500 mesh)

15

Titanium dioxide R996

10

[0064] 2. Preparation method:

[0065]1) First add linseed oil CS-100 into the tank, then add organic bentonite FR-100C under the condition of stirring at 800r / min, stir evenly and increase the speed to 1800r / min to disperse for 10 minutes;

[0066] 2) Under the stirring condition of 800r / min, add heavy calcium TP-1250, 2500 mesh barium sulfate, and titanium dioxide R996 in turn, stir evenly, increase the speed to 1800r / min and disperse for 15 minutes to obtain the product.

[0067] 3. The test results are shown in Table 6.

[0068] Table 6

[0069]

[0070] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com