Low-temperature waste heat power generation system

A technology of power generation system and low temperature waste heat, which is applied in the field of organic Rankine cycle system and can solve the problems of low efficiency of the cycle system and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

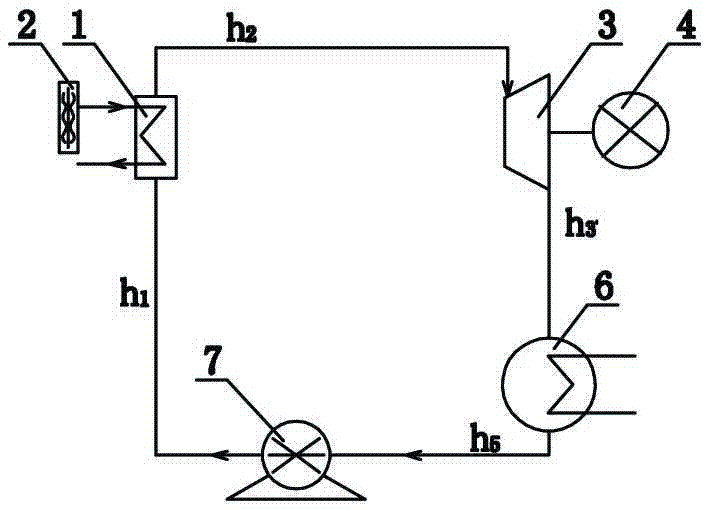

Embodiment 1

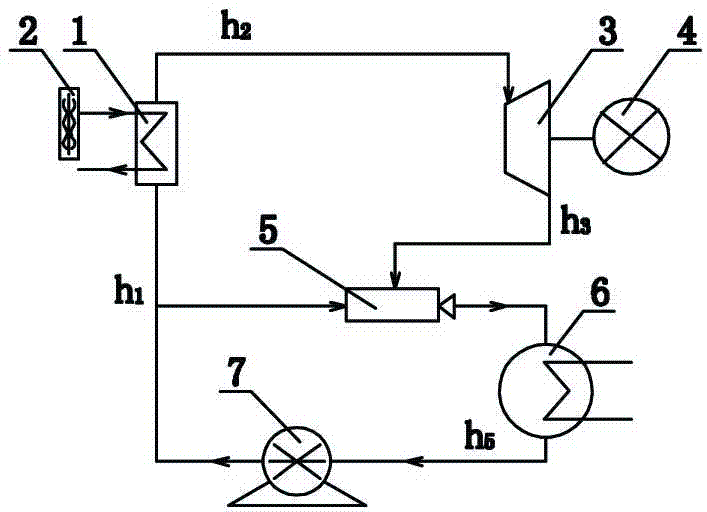

[0017] Such as figure 2 As shown, a low-temperature waste heat power generation system includes an evaporator 1, an expander 3, a condenser 6, a working medium pump 7 and an ejector 5, wherein the outlets of the working medium pump 7 are respectively connected to the evaporator 1 The inlet of the working fluid and the high-pressure inlet of the ejector 5, the outlet of the working fluid of the evaporator 1 is connected to the inlet of the expander 3, and the outlet of the expander 3 is connected to the low-pressure inlet of the ejector 5 , the expander 3 is connected to the generator 4, the medium pressure outlet of the ejector 5 is connected to the inlet of the condenser 6, and the outlet of the condenser 6 is connected to the inlet of the working medium pump 7.

[0018] The system adopts a closed Rankine cycle, and uses organic liquid R245fa instead of water as a circulating working medium to improve heat exchange efficiency. The organic working medium enters the evaporator...

Embodiment 2

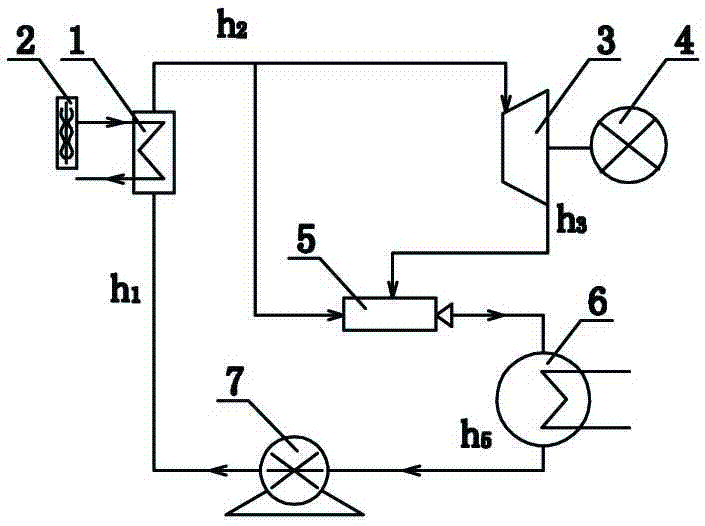

[0029] The difference between this implementation and embodiment 1 is: as image 3 As shown, a low temperature waste heat power generation system, the outlet of the working medium pump 7 is connected to the working medium inlet of the evaporator 1, and the working medium outlet of the evaporator 1 is respectively connected to the high pressure inlet of the ejector 5 and the Describe the inlet of the expander 3.

[0030] In the circulation process of the present invention, the liquid working medium is boosted in the working medium pump 7, enters the evaporator 1 and absorbs heat from the low-temperature heat source 2 to generate organic vapor, a part of the organic vapor enters the high-pressure inlet of the ejector 5, and a part of the organic vapor Push the expander 3 to rotate and do work, and drive the generator 4 to generate electricity. The organic vapor that has done work in the expander 3 becomes exhaust gas and enters the low-pressure inlet of the injector 5. The orga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com