Test machine for service life of valve core of water heating product

A testing machine and product technology, applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve the problem of inability to verify whether the technical performance, structure, and quality of the product are reasonable, whether it meets relevant standards, or cannot be accurately detected Problems such as the life of the spool of plumbing products, the accuracy and accuracy of the life of the detection spool, etc., to achieve the effect of convenient and unified processing, preventing energy loss, and reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

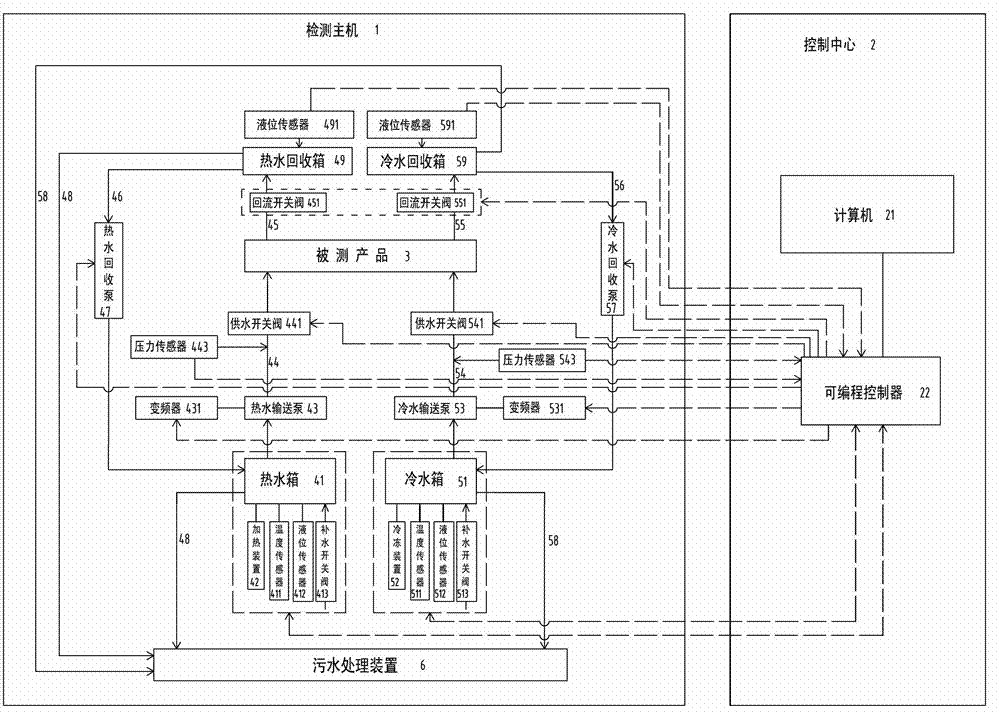

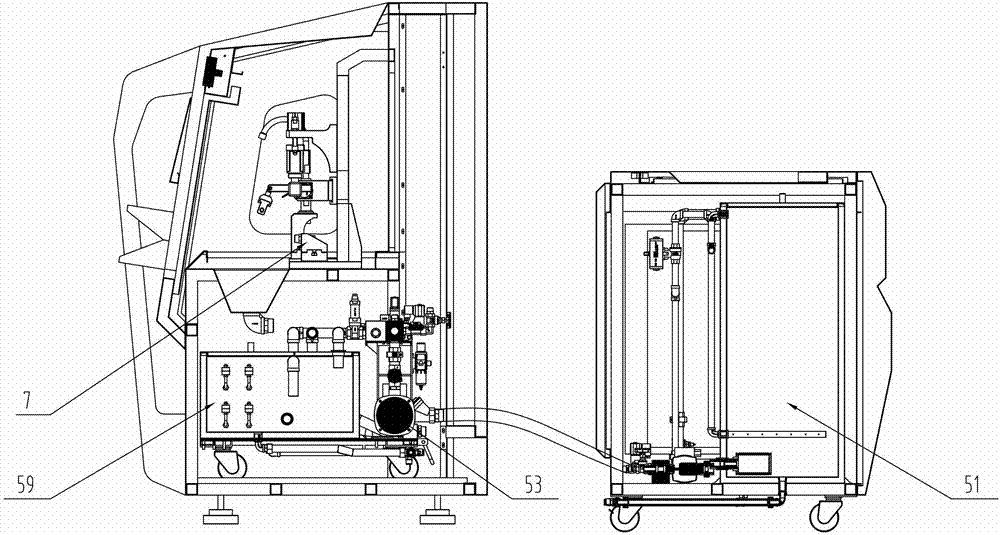

[0030] refer to figure 1 , figure 2 As shown, a plumbing product spool life detection machine includes a test device 7 for fixing the tested product 3 and operating the tested product 3 to repeatedly perform various water discharge actions, a water supply system, a programmable controller 22 and a computer 21, The water supply system includes a cold water circulation system and a hot water circulation system. The test device and the water supply system are set in a detection host 1, and the programmable controller 22 and the computer 21 are set in a control center 2. The detection host 1 and the control center 2 are independent of each other. , wherein, the computer 21 can also be replaced by an intelligent man-machine interface.

[0031] The cold water circulation system includes a cold water tank 51, a cold water delivery pump 53, a cold water recovery tank 59, a cold water recovery pump 57, and a freezing device 52. The cold water tank 51 and the cold water recovery tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com