Polysilicon resistor structure and method of forming the same

A polysilicon resistor and resistor technology, applied in circuits, electrical components, electrical solid devices, etc., can solve the problems of unstable electrical characteristics and high temperature of integrated circuits, and improve the temperature stability of resistance, reduce the variation range, and improve temperature stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

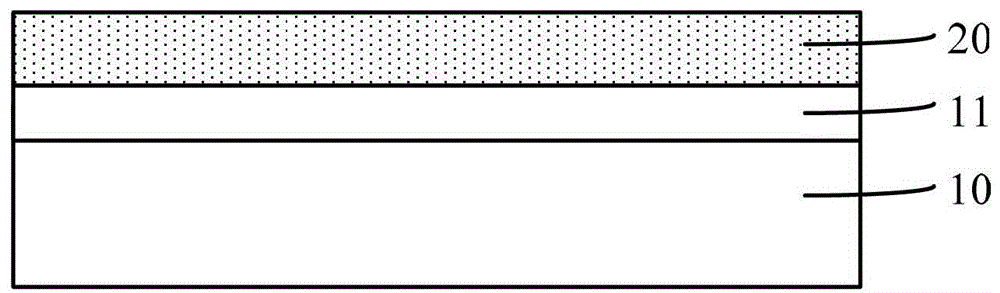

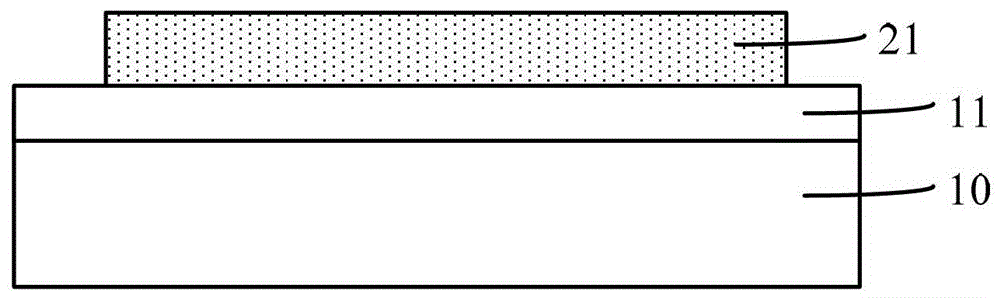

[0041] Please refer to Figure 7 ~ Figure 11 , is a schematic cross-sectional structure diagram of the formation process of the polysilicon resistance structure according to the first embodiment of the present invention.

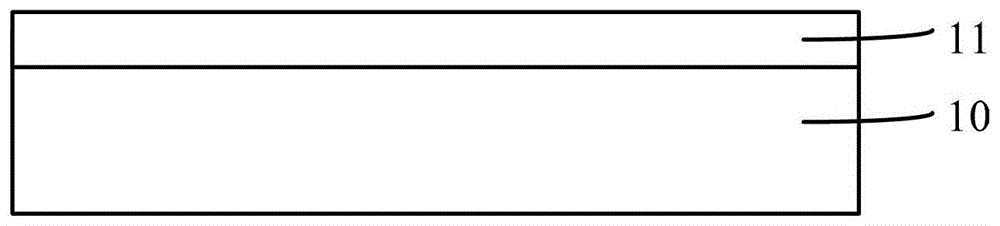

[0042] Specifically, please refer to Figure 7 , a substrate 100 is provided, and an isolation layer 101 is formed on the surface of the substrate 100 .

[0043] The substrate 100 can be a semiconductor substrate such as a bulk silicon substrate, a bulk germanium substrate, a silicon germanium substrate, a silicon carbide substrate, a silicon-on-insulator substrate, or a germanium-on-insulator substrate, or a ruby substrate, a sapphire substrate, etc. Insulating substrates such as substrates and glass substrates.

[0044] In this embodiment, the substrate 100 is a bulk silicon substrate. Since the bulk silicon substrate is doped with impurity ions, it has conductivity. Therefore, before forming the polysilicon resistor, the bulk silicon substrate and the...

no. 2 example

[0092] In the second embodiment of the present invention, a polysilicon resistor, a first metal silicide layer, a second metal silicide layer, a first interlayer dielectric layer, a first conductive plug, a second conductive plug, a first metal layer, and a second conductive plug are formed. The formation process of the second metal layer is consistent with the formation process in the first embodiment, please refer to the first embodiment Figure 7 ~ Figure 11 , which will not be described here.

[0093] Please also refer to Figure 11 with Figure 12 After forming the first metal layer 122 and the second metal layer 132, a second interlayer dielectric layer 160 is formed on the surfaces of the first metal layer 122, the second metal layer 132 and the first interlayer dielectric layer 150, and A third conductive plug 123 is formed in the second interlayer dielectric layer 160 and on the surface of the first metal layer 122, and a top metal layer is formed on the surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com