Method for measuring contamination degree of surface of electric power insulator

A measurement method and insulator technology, applied in the direction of measuring devices, specific gravity measurement, weighing by removing certain components, etc., can solve the problems of splashing of dirty solutions, errors, long filtration period, etc., to reduce sampling measurement errors, shorten Sampling measurement cycle, easy to grasp and promote the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

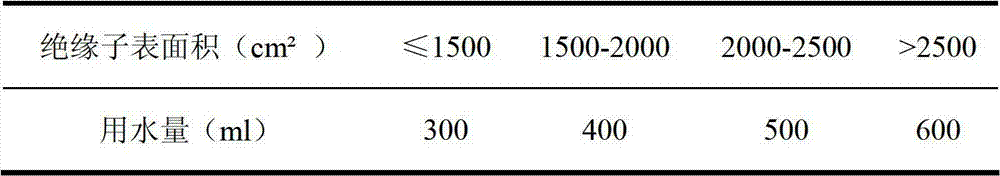

[0016] The method for measuring the surface pollution degree of electric insulators of the present invention uses a clean sampling cloth to clean and wipe the dirt on the surface of the insulator, weighs the quality difference m1 of the clean sampling cloth before sampling and after sampling, and immerses the dirty sampling cloth in deionized water after sampling to make the soluble Dissolution of pollution, measure the conductivity of the deionized aqueous solution containing pollution, convert the mass of soluble pollution in m2 and convert it into salt density, and the mass of insoluble pollution is m1-m2, and convert it into gray density to obtain the surface pollution degree of power insulators.

[0017] The above method of sampling and measuring the surface pollution degree of power insulators can be realized through the following steps:

[0018] (1) Put the clean sampling cloth into the corresponding paper cup, and then put the paper cup into a 60°C constant temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com